Maximize Your Warehouse Storage: How Much More Can You Store?

Have you heard that narrowing your aisles could increase your warehouse storage capacity? It’s true—by optimizing your aisle dimensions, you can potentially store many more pallets without expanding your space. But how much more exactly? Before making changes to your warehouse design, it’s crucial to estimate the increase in pallet storage based on different aisle widths.

With our warehouse storage capacity calculator, you can easily compare how aisle dimensions impact pallet storage. You’ll be able to see how much additional storage you can gain by narrowing your aisles to accommodate different types of lift trucks.

Lift Trucks and Aisle Widths

Not all lift trucks are the same, and the width of your aisles needs to account for the type of truck you use:

1) 4-Wheel Counterbalance Trucks require wider aisles.

2) Reach Trucks need narrower aisles.

By entering the truck types and aisle widths into the calculator, you can determine:

1) How many additional pallets you can store.

2) The percentage increase in storage capacity achieved by reducing aisle width.

Pallet Storage Based on Lift Truck Type and Aisle Width – Calculator

What Does the Calculator Do?

The calculator allows you to explore various pallet racking designs based on the aisle widths required for different lift trucks. It helps you assess:

The optimal aisle width for your specific truck types.

The increase in storage capacity from wide aisles to narrow or very narrow aisles.

How to Use the Calculator

1) Enter the dimensions: Input the length and width of the area you plan to rack.

2) Decide pallet width: Choose how many pallets wide you’ll store on each beam (typically 2 or 3).

3) Specify depth and height: Enter how many pallets deep you’ll store and how high you’ll stack them (floor + beam levels).

4) Select lift trucks: Choose the truck type to see how it affects aisle width and storage capacity.

The calculator then compares pallet storage for different lift trucks and aisle widths. It shows you the benefits of narrowing your aisles to boost storage efficiency using more compact lift trucks.

Why Narrowing Aisles Matters

Narrowing aisles, where feasible, can lead to significant space savings and increased storage capacity. Whether you’re working with standard forklifts or considering switching to trucks that can operate in tighter spaces, this tool will help you make data-driven decisions to get the most out of your warehouse.

Disclaimer: This calculator is for demonstration purposes only. For precise calculations and a detailed warehouse layout, contact us for an AutoCAD plan tailored to your warehouse’s column grid and egress plan.

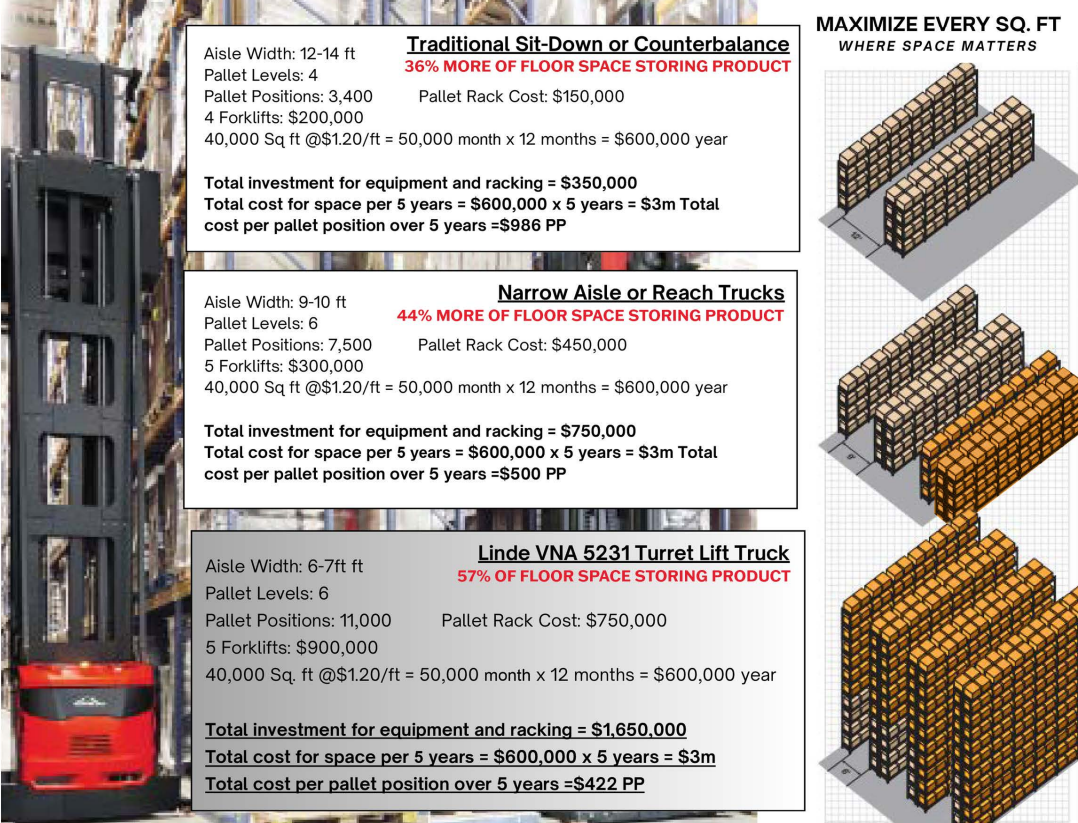

Learn More: Capacity and Throughput Comparison PDF

Let’s Talk

Want to discuss improving your storage density and cutting down on rack installation time and costs with our Total Warehouse Engineers? Whether you’re looking to optimize your existing space or design a new warehouse, our experts are here to help. Contact us today to schedule a meeting and explore how we can help you store more pallets in less space.

About the Author:

Dom is an engineering manager at Total Warehouse with extensive experience in optimizing warehouse spaces and designing innovative pallet racking systems. With a career spanning over 8 years, he has successfully led cross-functional teams to implement solutions that improve operational efficiency and maximize storage capacity. Known for his expertise in lean manufacturing principles and warehouse automation, Dom has delivered projects that not only reduce costs but also enhance safety and workflow. With a proven track record in both design and execution, Dom is a trusted expert in warehouse optimization.