Choosing Pallet Racking Styles: Teardrop, Structural Sammons & More

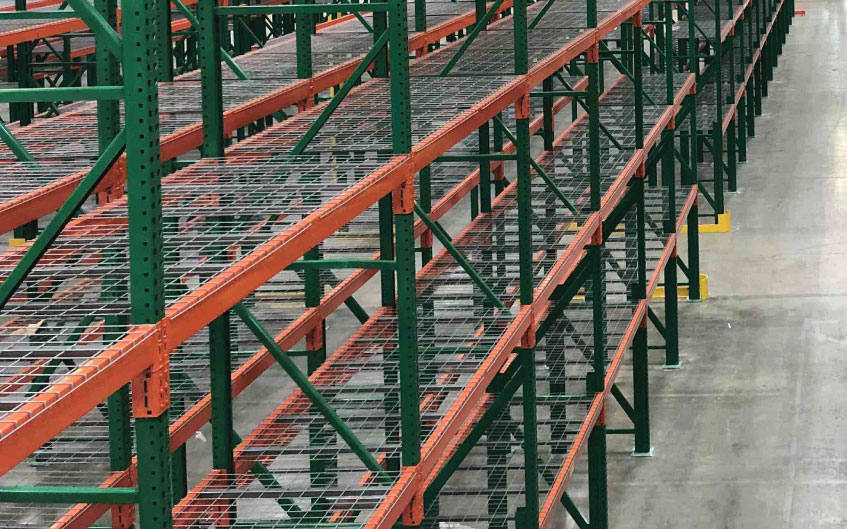

Pallet racking comes in a variety of styles, and understanding which one suits your operation best can be crucial for optimizing your warehouse space. At Total Warehouse, we specialize in helping businesses identify the perfect pallet racking setup, from engineering and installation to providing additional equipment like lighting and safety features to take your warehouse from early construction to full operation.

This guide will introduce you to the eight most common pallet racking styles found across the United States. Keep in mind that not all racking styles are compatible with each other, and choosing the right one can significantly impact your warehouse’s efficiency. Read on to learn more, and know that Total Warehouse is here to assist with every step of the process, from planning to installation.

Inspection of Pallet Rack Beams & Upright Connections

To determine the style of pallet racking you need, start by inspecting the connection points between the beams and uprights. Different types of connectors are often linked to specific manufacturers, with common options like hook & slot, pin & slot, or bracket and fastener connections. While some styles may appear similar at first glance, you can identify them by looking for defining features, such as locking mechanisms. Additionally, colors often vary by manufacturer, with certain color combinations being exclusive to specific brands.

Below is a breakdown of common pallet racking styles to help you make an informed decision.

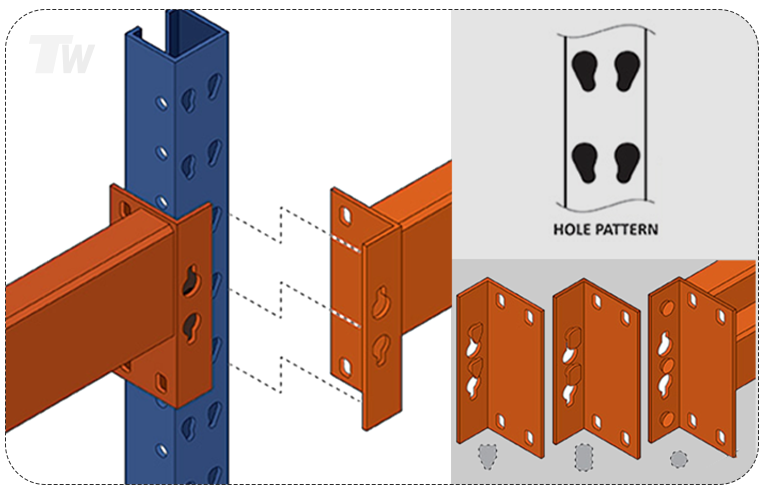

Teardrop Rack Style

The Teardrop style, also known as Interlake Old-Style, is the most widely used racking in the USA. It gets its name from the inverted teardrop-shaped slots on the uprights. Load beams in this style feature circular pins that lock easily into the slots, making installation quick and secure. Teardrop racks are commonly found in warehouses with orange load beams and blue uprights.

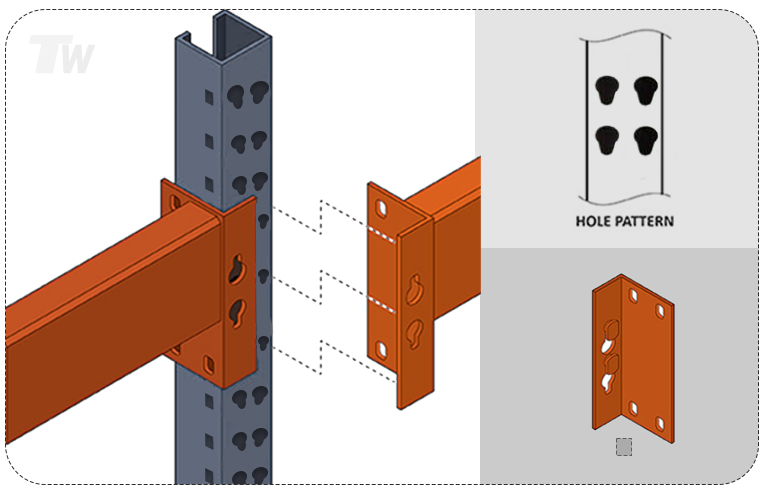

Sammons Rack Style

Sammons racking is most commonly seen on the West Coast. While it may resemble the Teardrop style at first glance, its distinctive feature is the mushroom-shaped connector pins that fit into slots spaced 4 inches apart. This style is typically paired with grey load beams and uprights.

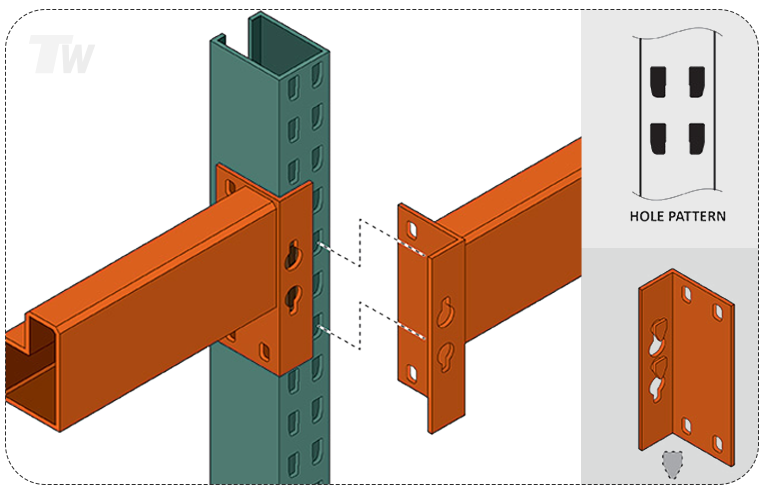

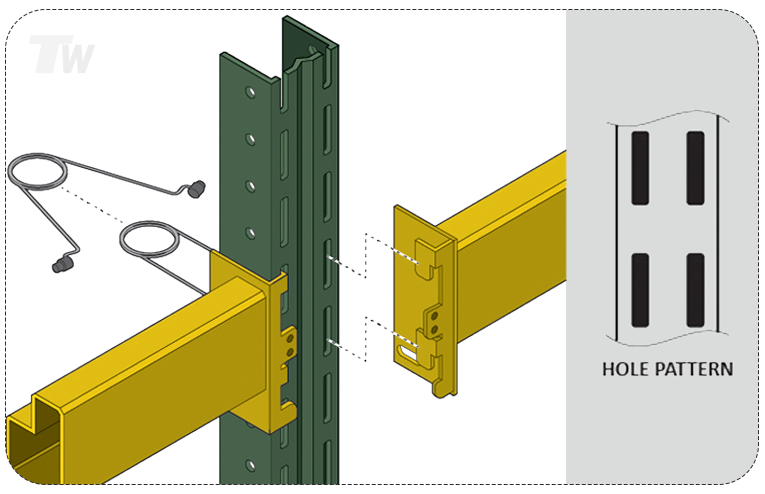

Newstyle Rack (Interlake New Style)

Newstyle racking, also known as Interlake New Style, is compatible with Teardrop racking. This versatility makes it a great option when you need to mix and match components, especially if you are sourcing used materials. Newstyle uprights feature rectangular slots, with pins spaced 2 to 4 inches apart on the load beams. This style is commonly found with orange load beams and green uprights.

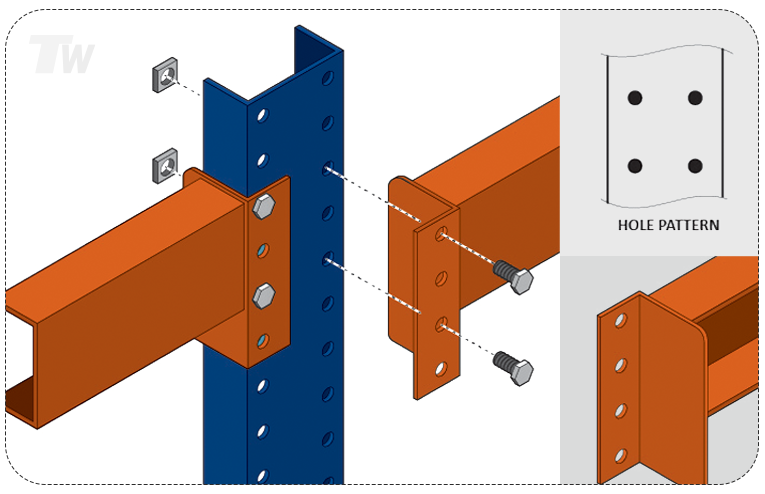

Structural Rack Style

If you’re dealing with heavy loads, Structural Style racking is designed for durability and strength. Made from hot-rolled steel, this racking uses bolts to connect load beams directly to the uprights, rather than hooks or pins. Structural uprights come in both single column and closed post varieties, offering extra reinforcement. This style is perfect for high-capacity warehouses needing extra durability.

Ridg-U-Rak Rack Style

Ridg-U-Rak racking features a hook & slot connection and can be identified by its unique rectangular slots on the uprights. The beams are relatively thin and connect to the uprights with a spring component and two pins that lock securely into place. This design makes Ridg-U-Rak a sturdy yet flexible option for many warehouses.

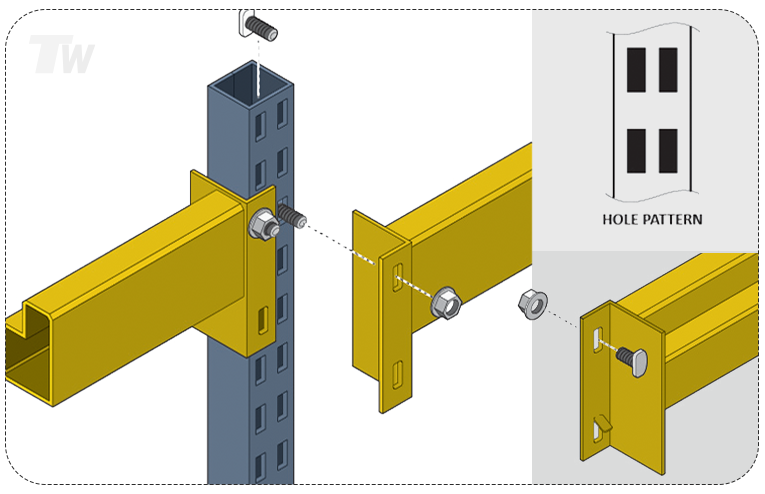

T-Bolt Rack Style

T-Bolt racking is easy to spot due to the rectangular slots on both the columns and load beams. The load beams are attached with bolts, ensuring a secure connection that’s especially useful in high seismic areas. T-Bolt racks usually come with blue uprights and yellow load beams.

Conclusion

With this guide, you should now have a better understanding of the most popular pallet racking styles in the U.S. However, if you’re still unsure or need professional advice, Total Warehouse is here to help. Our team of experts can guide you through selecting the best racking system for your needs, and we provide full engineering, installation, and equipment solutions to ensure your warehouse operates at its full potential.

Contact us today to get started on optimizing your warehouse from the ground up!