Key Features

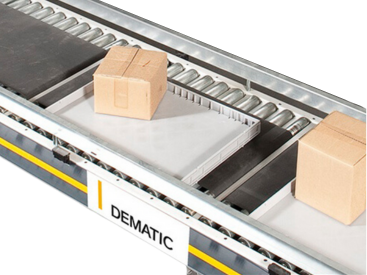

Dematic’s MCS enhances operational flexibility, allowing easy modification without replacing the entire system. Its universal side channel supports all conveyor models, making it simple to add, reconfigure, or replace modules. The global metric design uses common components, streamlining maintenance and reducing spare parts.

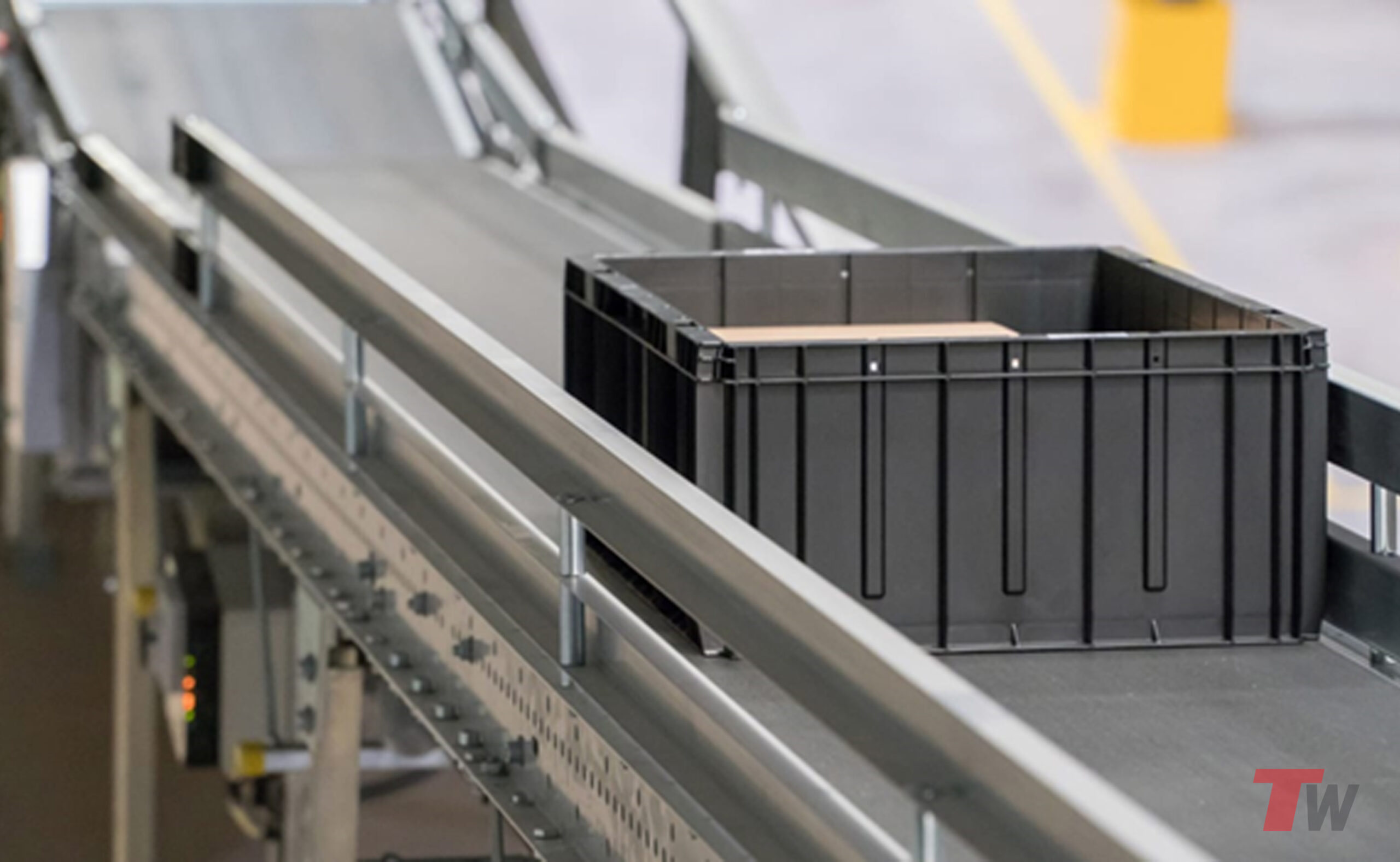

Dematic MCS handles cases, totes, trays, polybags, and parcels, ensuring efficient material flow. It integrates with workstations, scanners, sorters, label printers, case sealers, weigh scales, palletizers, and robotics. Functions include transport, accumulation, gapping, and diverting.

Dematic MCS combines AC drive motors, low-voltage motor-driven rollers, or both for an optimized conveyor layout. A single AC motor is ideal for long runs, reducing costs compared to multiple rollers.

Features include quiet rollers with double spring action, plastic-coated axles, and sealed-for-life bearings. High-strength, one-piece vulcanized belts provide precise carton control and handle lightweight or polybagged items. The segmented belt conveyor, powered by motor-driven rollers, features automatic tracking and tensioning.

Our conveyor solutions optimize material handling with versatile functionality. They efficiently transport, accumulate, and sort products, creating precise gaps and diverting items to multiple destinations.

Designed to enhance efficiency and flow, our systems support seamless movement and strategic sorting.

Dematic Pallet Conveyor uses integrated unit load technology to efficiently transport pallets, skids, tubs, and carts. It offers functions like transport, accumulation, diversion, rotation, and tilting.

Designed for seamless integration with systems like AS/RS, palletizers, and stretch wrap machines, it features a universal side channel and standardized components. Available in Roller and Chain options.

Durable goods manufacturers rely on automated conveyor systems to streamline the movement of work-in-process (WIP) inventory across production areas.

These systems efficiently transport large or heavy components between workstations such as cutting, welding, assembly, and quality inspection, reducing manual handling and labor costs.

By ensuring consistent material flow, conveyor systems enhance production speed, accuracy, and overall efficiency, helping manufacturers optimize their operations.

In parcel and postage operations, automated conveyor systems are essential for efficient cross-docking, both inbound and outbound.

These systems use a network of moving belts or rollers to transport packages through various stages, from sorting by destination to final packaging and loading.

By incorporating barcode scanning and other technologies, the conveyors accurately identify and direct each parcel, minimizing manual handling and speeding up delivery times.

Automation Specialists

Total Warehouse is your trusted specialist in Material Handling Automation Systems. With extensive experience, we create tailored solutions to address your unique business challenges. Powered by our partnership with Dematic, we deliver best-in-class solutions designed to optimize your warehouse operations.

Dematic Modular Conveyor

Flexible, Scalable, and Versatile

The Dematic Modular Conveyor features a universal metric side frame across all modules, making reconfiguration easy as operational needs evolve. With over 40 standard models, it supports a range of functions, including transportation, accumulation, gapping, and diverting—such as right-angle transfers and steerable wheel diverts. Available in multiple standard widths and configurations, the system offers horizontal, inclining, and declining sections, along with straight, curved, or angled junctions (wedges) to accommodate diverse material handling requirements.

Lease Rates

We can deliver the columbia journeyman today

Daily

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveWeekly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveMonthly

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

Reservelong term

Starting Atrequest quote

24/7 availability

- Plenty in stock at all TW locations

- WE DELIVER!

May vary upon evaluation

ReserveStill not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.