3 Compelling Reasons to have a PM Agreement

Having a planned maintenance agreement is essential for maintaining the health of your warehouse forklift fleet for many reasons.

In the material handling industry and equipment upkeep, preventative maintenance (PM) stands as the cornerstone, endorsed by OEMs for its efficacy in sustaining operational efficiency. By conducting regular, scheduled checks, this proactive approach aims to identify potential issues early on, ensuring the continued smooth functioning of equipment. This practice involves comprehensive inspections of safety components and preemptive detection of any signs of impending part failure, mitigating the risk of larger issues down the line.

It is imperative that your forklift maintenance service provider is completing both preventative and routine maintenance on your equipment.

Explore Our Forklift Repair and Service Programs.

1) During a standard PM Service inspection, a technician has the ability to identify wear items before they reach the point of failure, breakage, or cause damage to other components.

Service techs can also pinpoint safety-related issues that are currently inoperable and propose suitable replacements to mitigate potential liability for your company. Additionally, the tech can alert you to any broken or damaged parts that might lead to failures before the next scheduled PM Service, thereby minimizing downtime. Without such inspections, these issues may remain unnoticed until a failure or accident occurs.

The technician provides a thorough evaluation of the unit’s condition, highlighting potential problems. This proactive approach allows you to plan ahead, ensuring the lift truck operates safely and efficiently.

2) Furthermore, a Service Agreement for Preventive Maintenance (PM) serves as a clear reflection of a service company’s capabilities.

It is imperative that your repair company collaborates with you to minimize your overall operating costs. Key aspects include punctuality in delivering PM services, and making sure that the necessary maintenance and repair parts are readily available on the service vehicle.

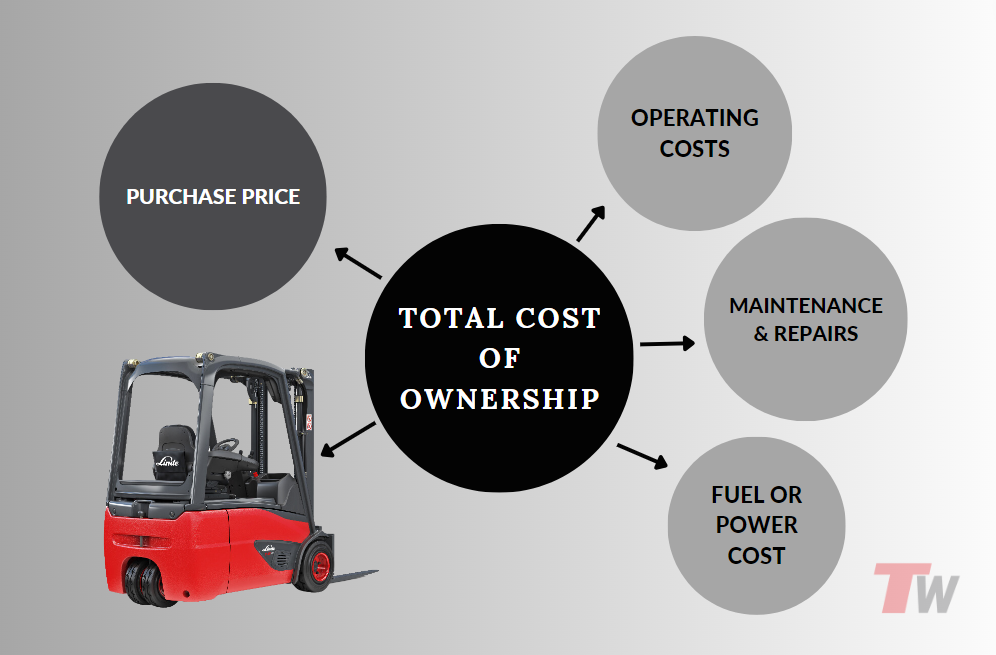

These elements collectively play a crucial role in diminishing repair expenses and minimizing equipment downtime. This ultimately lowers your overall cost of ownership and generates substantial value for both you and your business. A PM agreement serves as a testament to a company’s dedication and competence in supporting YOUR business.

3) Thirdly, through diligent equipment maintenance, you not only cut down on ownership expenses but also enhance the retained value of your equipment.

This results in a higher trade-in value when it comes time for replacement.

Total Warehouse Forklift Repair and Service Programs

For forklift maintenance and repair needs, contact our specialists at Total Warehouse. Whether you have a single truck requiring service annually or a fleet of 100 trucks needing attention every 30 days, we will customize a PM agreement that aligns perfectly with your business needs.

We provide repairs, service & maintenance for a wide range of forklifts, pallet jacks, & order pickers aimed at maximizing the value of your investment and minimizing the total cost of ownership. We recognize that forklift maintenance isn’t one-size-fits-all.

Explore Our Forklift Repair and Service Programs.

At Total Warehouse, we provide a range of service and parts programs to guarantee that you get optimal value for your investment, along with the most cost-effective ownership experience. We deliver high-quality products and services at competitive prices, representing products manufactured by Linde, UniCarriers Forklift, Big Joe Manufacturing, and Landoll. We’ve helped countless of businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.