Forklift Capacity Chart & Overview

Selecting a forklift can be overwhelming, especially when considering the numerous specifications involved. This article simplifies forklift selection by focusing on weight capacity, a crucial factor for any warehouse. For a basic overview of capacities of various types of forklifts, the forklift capacity chart below will provide good reference, outlining the maximum weight a specific forklift model can safely lift and maneuver at various heights. This information prevents overloading, which can cause tip-overs, product damage, and serious injuries. Whether you’re selecting a new forklift or optimizing your existing fleet, knowing your load requirements and referencing a forklift capacity chart ensures you make the right choices for your warehouse’s unique needs.

How Can You Check the Load Capacity of a Forklift?

To check the load capacity of a forklift, one must first consult the data plate, which provides crucial information such as the rated maximum capacity and load center. The load capacity chart, often included on the data plate, indicates the maximum weight the forklift can lift at various mast stages and load centers. It’s essential to understand that the shape and size of the load affect the capacity; longer objects have a larger load center, reducing the maximum weight that can be safely lifted.

Attachments also play a role; each has its own rated capacity, and the forklift’s overall capacity is limited by the lowest-rated component. When adding attachments post-purchase, the forklift must be re-rated by the manufacturer to ensure safety and compliance with OSHA standards. As the lifting height increases, the load capacity decreases due to the construction of the forklift’s multi-stage mast.

Calculating the net capacity involves accounting for factors such as de-rated capacity, mast type, and any modifications. The load center is a critical factor; it’s the distance from the vertical face of the forks to the load’s center of gravity, and not centering the load at the ideal load center can lower the carrying capacity. To calculate the actual net capacity, you can use the formula:

![]()

High-Capacity Forklifts and Side loaders: When Regular Forklifts Aren’t Enough

For massive loads between 15,000 and 60,000 pounds, high-capacity forklifts are the answer. These industrial giants, like the Hubtex Roxx offered by Total Warehouse, tackle heavy-duty jobs. The Hubtex Roxx boasts exceptional maneuverability for its size, making it perfect for navigating tight spaces while handling hefty loads. It comes in capacities ranging from 8 tons to 30 tons and offers an optional electric steering system for increased space savings and efficiency. Additionally, the unique single-wheel steering reduces the turning radius significantly.

Similar to high-capacity forklifts, side loaders handle massive but long and bulky loads like lumber, pipes, or precast concrete. They carry cargo alongside the machine instead of in front, allowing them to maneuver exceptional lengths in narrow aisles. The CombiLift Sideloader has a max lifting height of 20 feet, mas lifting capacity of 6,000 lbs., and excels in the Aluminum, Building Materials, Logistics, Metals, Plastics, Steel, and Timber industry.

Tried and True: Sit-Down Electric Forklifts

Sit-down electric forklifts reign supreme for warehouse use due to their emphasis on operator comfort. Their spacious design and ergonomic joystick controls minimize driver strain during long shifts. Additionally, electric power makes them ideal for indoor environments because they produce no harmful emissions, unlike propane-powered forklifts. However, their weight capacities typically range from 3,000 to 10,000 pounds, prioritizing maneuverability for lighter, pallet-sized loads.

There are so many options when it comes to Sit Down Electric forklifts, but for the best in class, I’d advise looking at this model as well as other Linde series.

Built for the Outdoors: Sit-Down Propane Forklifts

The dependable cousin of the electric sit-down forklift is the propane-powered model. Propane forklifts excel in outdoor applications due to their power for handling heavy loads and their overall design optimized for outdoor material handling. They prioritize operational ease, serviceability, efficiency, versatility, and safety in harsh environments.

Like their electric cousin, there are so many options when it comes to Sit Down Propane forklifts as well, , but for the best in class with a high 7,000 lb. lift capacity for the most rugged tasks, I’d advise looking at the Linde 1202.

Reaching New Heights: Order Pickers

Designed to retrieve individual items at varying heights, order pickers prioritize operator platform elevation over brute lifting power. Their weight capacities are typically lower, ranging from 1,000 to 3,000 pounds. This allows for a lighter chassis, enhancing stability when the platform is raised.

Some of the order picker models I’d recommend include the Linde 1355, with a picking height of up to 40 ft and the Big Joe J2 Joey with a shorter picking height of 6 ft which is great for low level tasks that have loads up to 1,500 lbs.

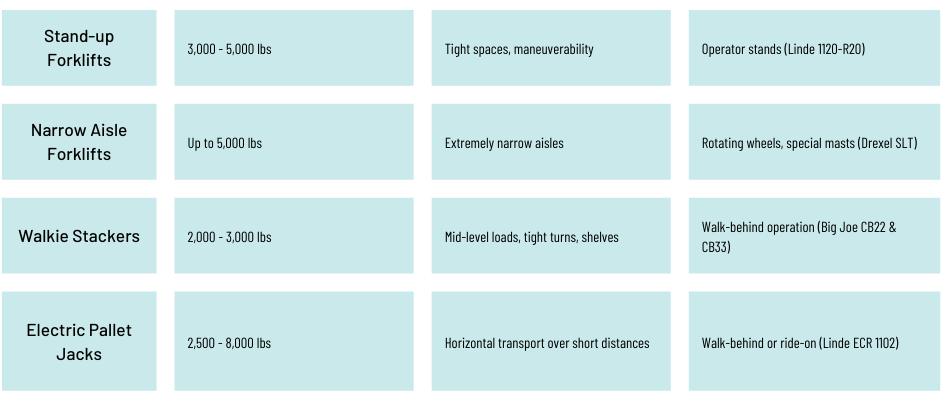

Compact and Agile: Stand-Up Forklifts

As the name suggests, stand-up forklifts require the operator to stand on a platform while operating. IN other words, you can think of Stand Ups as the upright relative of sit-down forklifts.

This design offers exceptional maneuverability in tight spaces and narrow aisles but comes at the cost of reduced operator comfort during extended use. Weight capacities for stand-up forklifts are generally lower than their sit-down counterparts, ranging from 3,000 to 5,000 pounds.

With its impressive lifting capacity of 5,000 lbs., the Linde 1120-R20 is a great option if you’re looking for a versatile reach truck that excels with palletized loads.

Forklifts for Tight Spaces: Narrow Aisle Forklifts

Narrow aisle forklifts are specifically designed to operate in confined warehouse aisles. They achieve this feat through innovative features like rotating wheels and special mast designs. While some models offer larger lift capacities, most are built to excel in tight spaces as narrow as 56 in. and handle around 3,000 lbs.

But if you’re looking for the best of both worlds then I’d consider investing in the Drexel SLT which can lift loads up to 5,000 lbs. and as high as 30 ft.

Walkie Stackers: Versatile and User-Friendly

Walkie stackers, also known as pedestrian stackers, offer a perfect blend of maneuverability and lifting capacity for mid-level loads in warehouses. Unlike traditional forklifts, they do not have a seat for the operator, who instead walks behind the machine. This design allows for exceptionally tight turns and makes them ideal for stocking shelves, loading and unloading trucks, and transporting pallets over short distances.

Walkie stackers typically handle loads ranging from 2,000 to 3,000 pounds, making them suitable for a wide variety of warehouse tasks. Their lifting heights are generally lower than those of forklifts, reaching up to 12 feet. This focus on maneuverability and mid-level lifting makes them a cost-effective alternative to forklifts for specific applications.

For ultimate lifting power, the Big Joe CB22 & CB33 might be a great choice if this is the kind of forklift you’re considering.

Electric Pallet Jacks: Lifting Made Easy

Electric pallet jacks, though not technically forklifts, deserve mention due to their prevalence in warehouses. These low-profile, walk-behind or ride-on machines are designed for horizontal load movement over short distances. Their lifting capacities range from 2,500 to 8,000 pounds, making them ideal for transporting palletized goods.

Total Warehouse boasts a large fleet of electric pallet tracks, so I’m sure we have one that meets your needs. But one model worth mentioning is the Linde ECR 1102 which lifts an impressive 8,000 lbs. and has a reliable run time of 8 hrs.

Beyond the Basics: Factors Affecting Capacity

Several other lifting capacity specifications can affect actual lifting capacity and should be reviewed before purchasing a forklift. These factors include:

✅ Load Center: The distance from the forklift’s forks to the center of gravity of the load. As the load center increases, the weight capacity decreases.

✅ Forklift Attachments: Certain attachments like clamps or side shifters can reduce overall weight capacity.

✅ Lift Height: The higher the lift height, the lower the weight capacity due to the forklift’s stability.

Choosing the Right Forklift for Weight Capacity

When selecting a forklift, considering the weight of the heaviest loads you intend to move is crucial. Of course, other specifications like battery life, lift height, and price will also influence your decision. This article provides a foundation for comparing lift capacity between forklift models and brands. If you have any questions about the forklifts mentioned in this article or others, our material handling experts are happy to assist you. You can reach us at totalwarehouse.com or call us at (833) 868-2500.