Why a Forklift Maintenance Checklist is Essential

A forklift maintenance checklist ensures safety, operational efficiency, and cost savings while minimizing downtime and avoiding expensive repairs. By performing regular inspections and preventative maintenance, businesses create a safer, more productive work environment.

Key Benefits of Using a Forklift Maintenance Checklist

✅ Enhanced Safety: Inspecting brakes, tires, and safety features prevents accidents and injuries.

✅ Improved Efficiency: Addressing minor issues early reduces operational disruptions and costly downtime.

✅ Cost Savings: Regular maintenance prevents expensive emergency repairs.

✅ Longer Equipment Life: Routine servicing minimizes wear and tear, extending the forklift’s lifespan.

✅ Compliance with Regulations: Ensures OSHA safety standard compliance for forklift operation.

✅ Higher Resale Value: Well-maintained forklifts retain value, leading to a better return on investment.

Forklift Maintenance Checklist: Key Inspection Areas

🔍 Pre-Shift Checks: Inspect tires, fluid levels, lights, horn, brakes, and safety devices before each shift.

🔍 Visual Inspections: Check for visible damage, leaks, loose components, and worn parts.

🔍 Fluid Level Checks: Monitor engine oil, hydraulic fluid, coolant, and battery fluid levels.

🔍 Tire Inspections: Examine tire pressure, tread depth, and damage.

🔍 Operational Checks: Test lifting/lowering functions, steering, and forward/reverse movement.

🔍 Safety Device Checks: Ensure seat belts, overhead guards, and emergency stop features work properly.

🔍 Cleaning & Lubrication: Regularly clean and lubricate key components to prevent damage.

🔍 Scheduled Maintenance: Follow the manufacturer’s servicing schedule for filter changes, component replacements, and adjustments.

How Often Should Forklifts Be Serviced?

Forklifts require full maintenance every 200–250 hours or every six weeks. OSHA mandates daily inspections to ensure safety.

Factors That Affect Maintenance Frequency:

- Age: Older forklifts require more frequent checks.

- Service History: If a part frequently malfunctions, it needs closer monitoring.

- Work Environment: Harsh conditions demand more frequent maintenance.

- OSHA Compliance: Following OSHA’s safety guidelines prevents violations and fines.

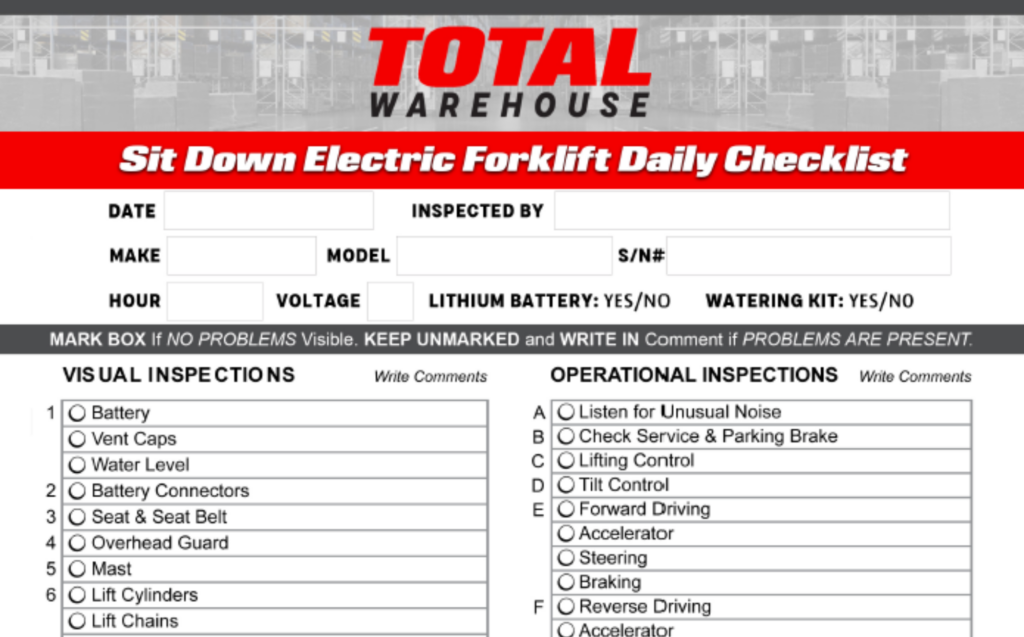

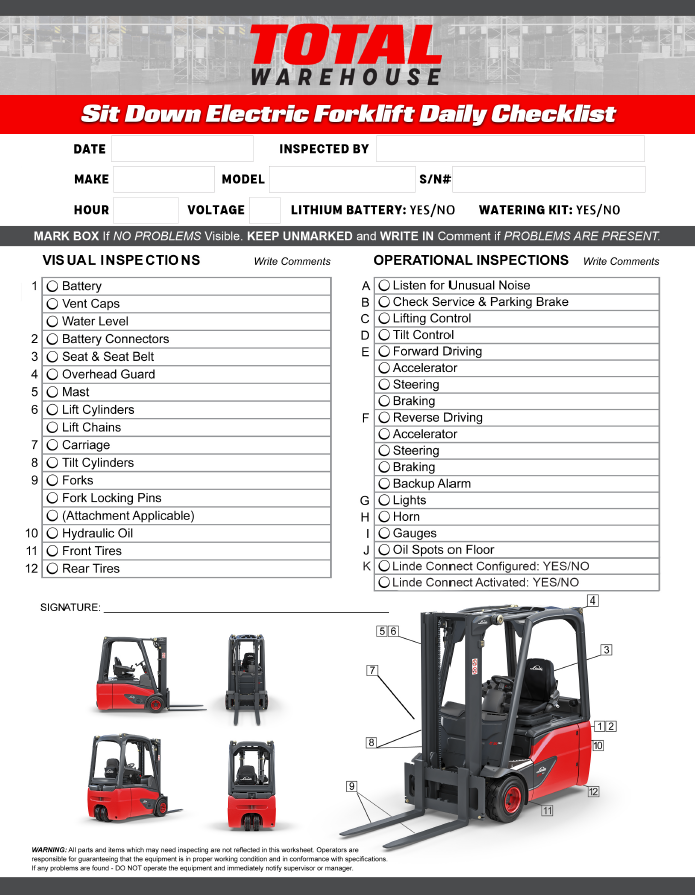

Daily Forklift Maintenance Checklist

🔹 Before Turning on the Forklift:

- Ensure hoses are properly connected.

- Inspect tires for deflation or damage.

- Test seat belts and safety devices.

- Check fluid levels.

- Inspect tines and overhead guard.

- Clean the operator compartment.

- Look for visible damage.

🔹 After Turning on the Forklift:

- Test steering, brakes, and accelerator.

- Check forward and reverse gears.

- Inspect pedals, handbrake, and clutch release.

- Raise and lower tines.

- Verify horn, lights, and backup alarm.

Long-Term Forklift Preventative Maintenance

📅 Monthly Checklist

- Check ignition time and spark plugs.

- Inspect drive belts and air filters.

- Change engine oil and filters.

- Lubricate chassis and mast.

📅 Quarterly Checklist

- Inspect lift chain tension and carriage rollers.

- Replace fuel filter and hydraulic pump.

- Drain water separator.

- Clean radiator.

📅 Semi-Annual Checklist

- Test brake booster operation.

- Check engine bolts and manifold nuts.

- Replace brake fluid.

- Monitor coolant levels.

- Apply wheel-bearing grease.

Forklift Maintenance Tips

- Regular Cleaning: Keep the forklift clean at the end of each workweek.

- Collision Inspections: Check forklifts for damage after any impact.

- Certified Maintenance Only: Only licensed operators and technicians should perform repairs.

- Use a CMMS: A Computerized Maintenance Management System helps track maintenance costs, schedule servicing, and monitor repairs.

- Address Issues Immediately: Delays in repairs increase safety risks and costs.

Forklift Maintenance by Type

⚡ Electric Forklifts

- Check battery cables and restraints.

- Monitor electrolyte levels.

⛽ Liquid Propane Forklifts

- Inspect propane tanks for leaks or damage.

- Ensure hoses and belts are secure.

- Verify the relief valve is pointing up.

🚜 Internal Combustion Forklifts

- Check engine oil, coolant, and brake fluid levels.

- Inspect air filter and radiator.

Forklift Repair Qualifications

- Certified Forklift Operators (CFOs) can perform basic inspections and identify issues.

- Certified Forklift Technicians (CFTs) handle major repairs and part replacements.

- Many businesses outsource repairs for cost-effectiveness.

How Much Does Forklift Servicing Cost?

- Annual maintenance costs: $1,500–$6,000.

- Factors affecting cost:

- Repair type: Minor exterior fixes cost less than internal repairs.

- In-house vs. outsourced repairs: In-house technicians require parts and training, while outsourced services may charge higher hourly rates.

Total Warehouse are proud dealers for Dematic, Linde, Big Joe, UniCarriers, and Landoll. We’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.