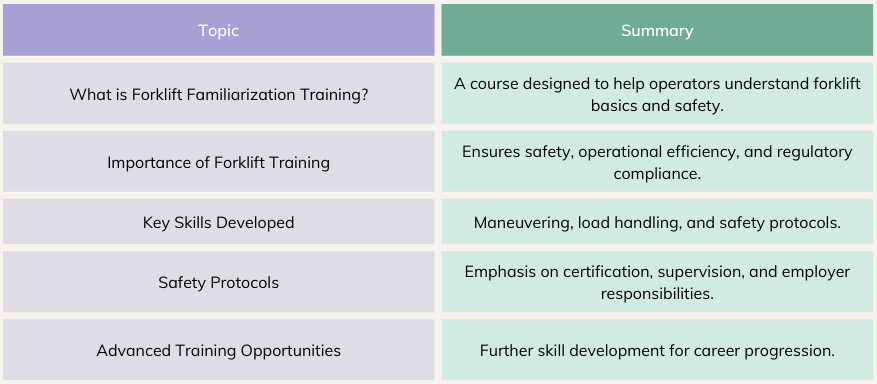

Key Takeaways

Introduction to Forklift Familiarization Training

Forklift familiarization training is a crucial step for any new or inexperienced forklift operator. This course is designed to provide operators with the knowledge and skills necessary to safely and efficiently operate forklift trucks within a warehouse or industrial setting. By undergoing this training, operators become proficient in handling the equipment, adhering to safety standards, and understanding the operational protocols that ensure a smooth workflow.

The importance of this training cannot be overstated. Proper training reduces the risk of accidents, ensures compliance with industry regulations, and enhances the overall productivity of warehouse operations. Moreover, it equips operators with the confidence and competence needed to navigate the complexities of material handling, ultimately contributing to a safer and more efficient working environment.

Why is Forklift Training Important?

- Safety: Reduces workplace accidents and injuries.

- Efficiency: Enhances operational productivity.

- Compliance: Meets regulatory standards and legal requirements.

- Career Advancement: Provides foundational skills for career growth.

Understanding Forklift Truck Basics

Before delving into the specifics of familiarization training, it’s essential to understand the basic components and functionalities of a forklift truck. Forklifts are versatile pieces of equipment designed to lift, move, and place heavy loads with precision. Key components include the mast, forks, counterweight, and operator cabin, each playing a critical role in the forklift’s operation.

Key Components of a Forklift

| Component | Description |

|---|---|

| Mast | Vertical structure that lifts and lowers the load. |

| Forks | Horizontal prongs used to pick up and carry loads. |

| Counterweight | Weight at the rear to balance the load being lifted. |

| Operator Cabin | Controls and protects the operator. |

Understanding these components helps operators recognize how the forklift functions and the importance of each part in maintaining balance and control. During familiarization training, operators learn to inspect these components for any signs of wear or damage, ensuring the equipment’s reliability and safety.

Common FAQs

Q: What types of forklifts are commonly used in warehouses? A: Common types include electric forklifts, LPG propane forklifts, order pickers, and pallet jacks.

Q: How often should forklift trucks be inspected? A: Daily inspections are recommended to ensure safety and operational efficiency.

Stages of Forklift Training

Forklift training typically progresses through three main stages: basic training, specific job training, and familiarization training. Each stage builds on the previous one, providing operators with a comprehensive understanding of forklift operation and safety.

Stages of Training

- Basic Training

- Covers general operating principles.

- Includes theoretical and practical instruction.

- Specific Job Training

- Tailored to the specific tasks and equipment used in the workplace.

- Focuses on the environment and operational nuances.

- Familiarization Training

- On-the-job training under supervision.

- Ensures operators can safely and efficiently perform their duties in real-world conditions.

Importance of Each Stage

- Basic Training: Lays the groundwork with fundamental skills and knowledge.

- Specific Job Training: Customizes learning to the job’s unique requirements.

- Familiarization Training: Reinforces skills in actual working conditions, ensuring readiness and safety.

Key Skills for Forklift Operators

Forklift operators must develop a range of skills to perform their duties safely and efficiently. These skills are honed during familiarization training, which focuses on practical, hands-on experience in a controlled environment.

Essential Skills

- Maneuvering: Operators learn to navigate tight spaces and complex layouts.

- Load Handling: Proper techniques for lifting, moving, and placing loads.

- Safety Protocols: Adherence to safety guidelines to prevent accidents.

- Equipment Inspection: Regular checks to identify and address potential issues.

Skill Development Areas

Common FAQs

Q: What is the most important skill for a forklift operator? A: Safety is paramount; understanding and adhering to safety protocols is crucial.

Q: How can operators improve their maneuvering skills? A: Regular practice in varied environments helps enhance maneuvering abilities.

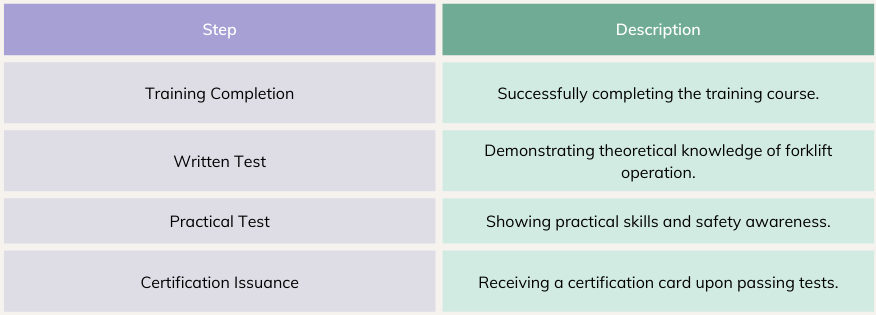

Safety Protocols and Certification

Safety is a critical aspect of forklift operation, and familiarization training places a strong emphasis on safety protocols and certification. Proper training and certification not only ensure compliance with industry regulations but also significantly reduce the risk of accidents and injuries in the workplace.

Safety Measures

- Regular Inspections: Daily checks of the forklift to identify any potential issues.

- Proper Load Handling: Techniques to avoid tipping and ensure load stability.

- Operator Awareness: Being mindful of surroundings and potential hazards.

- Protective Gear: Use of helmets, gloves, and other safety equipment.

Certification Process

Employers have a crucial role in ensuring that all operators are properly trained and certified, maintaining records of training, and providing continuous education on new safety protocols and equipment advancements. This commitment to safety and training helps foster a culture of safety within the workplace.

Common FAQs

Q: How often do forklift operators need to be recertified? A: Recertification is typically required every three years, but it may vary by region and employer policy.

Q: What are the consequences of not following safety protocols? A: Non-compliance can lead to accidents, injuries, legal penalties, and increased operational costs.

By emphasizing these key aspects, forklift familiarization training not only equips operators with the necessary skills and knowledge but also underscores the importance of safety and compliance in maintaining a productive and secure work environment.

Advanced Training Opportunities

After completing the initial stages of forklift familiarization training, operators have the opportunity to pursue advanced training courses. These courses are designed to enhance specific skills, improve safety protocols, and prepare operators for more complex tasks and responsibilities.

Types of Advanced Training

- Specialized Equipment Training: Focuses on different types of forklifts such as narrow aisle or rough terrain forklifts.

- Advanced Safety Techniques: Emphasizes advanced safety measures and emergency procedures.

- Supervisor Training: Prepares experienced operators for supervisory roles, including team management and training responsibilities.

Benefits of Advanced Training

- Enhanced Skills: Operators gain advanced skills that can increase efficiency and safety.

- Career Progression: Provides a pathway for career advancement within the warehouse industry.

- Operational Efficiency: Advanced training contributes to smoother and more efficient warehouse operations.

Common FAQs

Q: How does advanced training differ from basic training? A: Advanced training builds on basic skills, focusing on specialized equipment, advanced safety protocols, and leadership abilities.

Q: Who should consider advanced forklift training? A: Experienced operators looking to enhance their skills or advance their careers should consider advanced training.

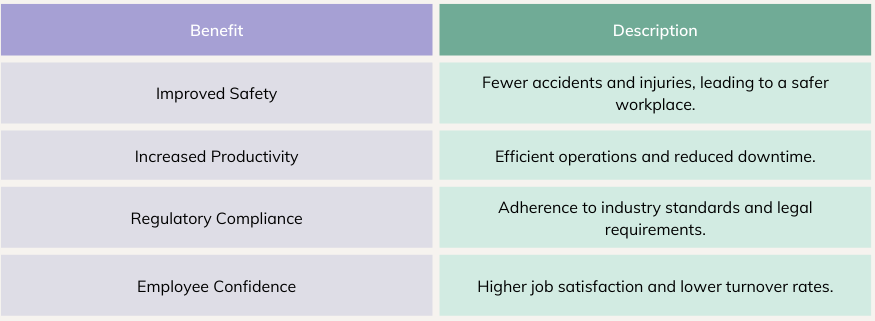

Benefits of Forklift Familiarization Training

Forklift familiarization training offers numerous benefits to both operators and employers. By investing in comprehensive training programs, warehouses can ensure a safer and more efficient working environment.

Key Benefits

- Improved Safety: Reduces the risk of accidents and injuries.

- Increased Productivity: Trained operators work more efficiently, reducing downtime.

- Regulatory Compliance: Ensures compliance with OSHA and other regulatory standards.

- Employee Confidence: Boosts operator confidence and job satisfaction.

Safety and Productivity

Common FAQs

Q: What impact does training have on warehouse productivity? A: Proper training significantly increases productivity by reducing errors and downtime.

Q: How does training contribute to regulatory compliance? A: Training ensures that operators are aware of and adhere to OSHA and other industry standards.

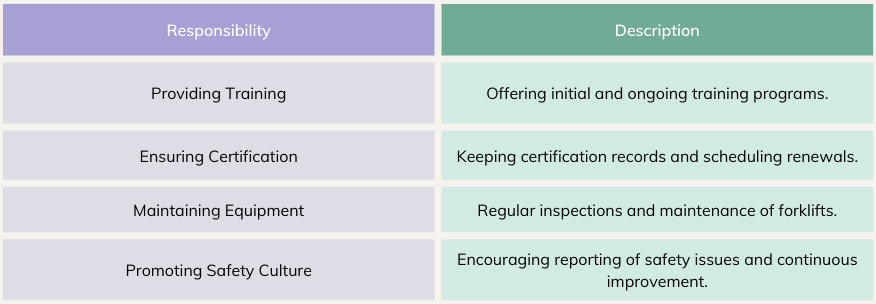

Employer Responsibilities

Employers play a crucial role in the successful implementation of forklift familiarization training. Ensuring that all operators are properly trained and certified is a key responsibility, along with maintaining an environment that prioritizes safety and continuous learning.

Key Employer Responsibilities

- Providing Training: Offering comprehensive training programs for all forklift operators.

- Ensuring Certification: Making sure all operators are certified and up-to-date with their training.

- Maintaining Equipment: Regularly inspecting and maintaining forklifts to ensure they are safe to use.

- Promoting Safety Culture: Encouraging a workplace culture that prioritizes safety and continuous improvement.

Support and Resources

Common FAQs

Q: How can employers ensure ongoing compliance with training requirements? A: Employers can schedule regular training sessions and maintain up-to-date records of certifications.

Q: What should employers do to promote a safety culture? A: Employers should encourage open communication about safety concerns and provide ongoing safety training.

Technology and Innovations in Forklift Training

As technology advances, new tools and methods are being developed to enhance forklift training programs. These innovations provide more effective training experiences and help operators stay current with the latest safety and operational standards.

Emerging Technologies

- Virtual Reality (VR) Training: Offers immersive training experiences that simulate real-world scenarios.

- Simulation Software: Allows operators to practice in a controlled, virtual environment.

- Online Training Modules: Provides flexible, self-paced learning opportunities.

Benefits of Technology Integration

- Enhanced Engagement: Interactive training methods increase engagement and retention.

- Cost-Effective: Reduces the need for physical training spaces and equipment.

- Up-to-Date Training: Keeps operators informed about the latest safety protocols and technologies.

Common FAQs

Q: What are the benefits of using VR in forklift training? A: VR provides a realistic and immersive training experience, improving skill retention and safety awareness.

Q: How can online training modules complement traditional training methods? A: Online modules offer flexible, self-paced learning that can be used to reinforce and expand on traditional training.

Conclusion: The Future of Forklift Training

Forklift familiarization training is an essential component of warehouse operations, ensuring safety, efficiency, and compliance. As technology continues to evolve, training methods will become even more effective and accessible, providing operators with the tools they need to succeed in their roles.

Final Thoughts

- Commitment to Safety: Continual emphasis on safety and training is crucial for maintaining a productive workplace.

- Embracing Technology: Leveraging new technologies will enhance training programs and operational efficiency.

- Ongoing Education: Lifelong learning and continuous improvement are key to staying competitive in the warehouse industry.

By investing in comprehensive training programs and staying current with technological advancements, warehouses can create a safer, more efficient, and more productive working environment for all employees.