Boost Warehouse Efficiency with Forklift Wire Guidance

Why Forklift Wire Guidance? Consumer demands and expectations are driving a significant increase in product volume and variety, necessitating warehouses to optimize space utilization and selectivity. One effective strategy is adopting narrow aisles, a concept pioneered by Total Warehouse. However, this shift can lead to potential risks such as increased lift truck, rack, and product damage.

To mitigate these challenges, Total Warehouse has introduced wire guidance technology to be used in AGV forklifts, which automatically guides forklifts through aisles, reducing operational impacts. This fully integrated system is available for very narrow aisle (VNA) lift trucks, including order pickers and turret trucks, allowing operators to focus on more productive tasks like order picking and pallet storing.

What are Wire Guidance Systems?

Wire Guidance is an advanced electronic and mechanical system designed to control the steering of VNA-enabled forklifts by tracking an energized guidewire embedded in the floor.

This guidewire is buried in a beveled cut approximately ½” to 5/8” deep within each aisle. Once wire guidance is activated, operators are relieved from steering duties, resulting in decreased product and rack damage, operator injuries, and lift truck impacts.

How Does the Forklift Wire Guidance Work?

1. A wire sensor, mounted along the centerline of the truck, receives signals from a wire embedded in a central groove in the aisle floor.

2. The truck’s sensors detect the signal from the floor wire and automatically control the steering mechanism, allowing the truck to follow the wire path precisely.

3. The wire guidance system is linked to the truck’s braking system, ensuring that the truck will automatically slow down and stop if the signal is lost.

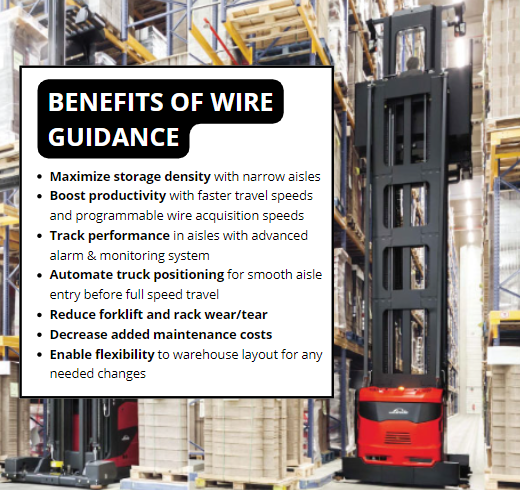

Benefits of Wire Guided Systems

Increased Productivity

With higher travel speeds and faster aisle entry, wire guidance significantly boosts picking productivity.

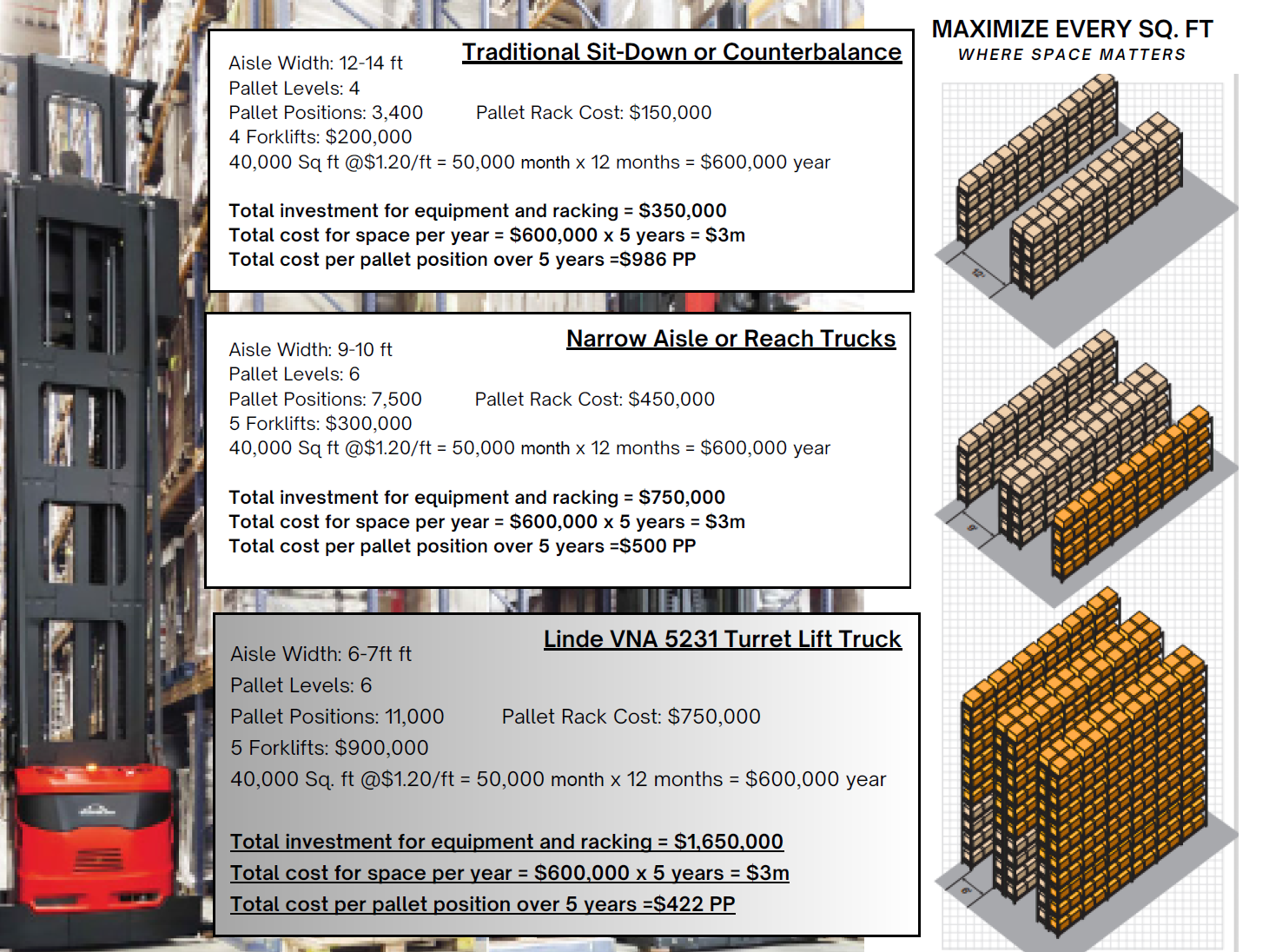

Optimized Space Utilization

Wire Guidance allows for closer aisles and floor-level storage, maximizing facility space utilization compared to rail guidance.

Reduced Costs

By freeing operators from steering responsibilities in VNAs, efficiency increases, and damage to racks, products, and forklifts is minimized.

Decreased Risks

Automatic slowdown and stop functions for navigation errors, as well as automated control for speed and height relationships, reduce risks to operators.

Types of Guided Forklifts

Wire-guided forklifts are exclusively VNA trucks, but what sets them apart from standard lift trucks? VNA forklifts, also known as turret trucks or swing reach trucks, or order pickers are specifically designed for high-density warehouses. These trucks allow for smaller aisles, enabling more goods to be stored and accessed. Their narrow and compact design ensures maneuverability through tight corridors, and their 180-degree rotating mast allows operators to access both sides of the aisle without repositioning the truck.

Wire-guided forklifts come with numerous customizations ideal for narrow aisle storage, including turret heads, compact turning, shuttle forks, load capacity, lift height, Personal Protection Systems (PPS), energy-saving Advanced Lifting Systems (ALS), and more.

Implementing wire guidance technology can transform warehouse operations, improving efficiency, safety, and space utilization. By leveraging this technology, warehouses can better meet the increasing demands of today’s market while maintaining a safe and productive environment.

How Wire Guidance Systems Impact the Autonomous Forklift Industry

Forklift wire guidance systems have revolutionized the efficiency and precision of Automated Guided Vehicles (AGVs) and autonomous forklifts in modern warehouses and distribution centers. These systems utilize a network of wires embedded in the facility’s floor to create invisible pathways that guide the vehicles along predetermined routes. By emitting a low-frequency signal, the wires enable AGVs and autonomous forklifts to navigate with remarkable accuracy, even in complex environments with multiple intersections and tight spaces.

One of the primary benefits of wire guidance systems for AGV forklifts is their ability to operate in narrow aisles and high-density storage areas. This precision allows warehouses to maximize their storage capacity by reducing aisle widths and increasing vertical storage. Additionally, wire-guided systems are highly reliable and less susceptible to interference from environmental factors such as dust, varying lighting conditions, or changes in floor surfaces, which can affect other navigation technologies like laser or vision-based systems.

Furthermore, wire guidance systems contribute to enhanced safety and reduced operational costs. By following predefined paths, AGVs and autonomous forklifts minimize the risk of collisions with infrastructure or other vehicles, leading to fewer accidents and less damage to goods and equipment. The system’s reliability also translates to reduced downtime and maintenance requirements, as there are fewer moving parts compared to traditional forklifts. This combination of improved safety, increased efficiency, and lower operational costs makes wire guidance systems an invaluable asset for businesses looking to optimize their material handling processes and stay competitive in the rapidly evolving logistics industry.

At Total Warehouse, we’ve helped countless businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability by making the switch. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.