Watering Forklift Batteries | Forklift Battery Maintenance

The Essential Guide to Watering Forklift Batteries: Maximize Lifespan & Performance

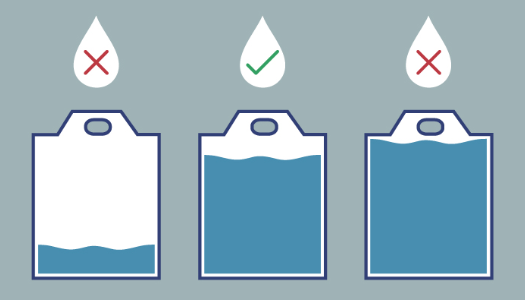

Watering forklift batteries can feel like a delicate balancing act. Too much water can lead to dangerous boil-over, while too little can dry out the cells, significantly shortening battery life. Both scenarios can take a serious toll on your battery’s longevity and performance, leading to costly replacements. But with a proper battery watering routine, you can extract every bit of power from your forklift batteries and keep them running efficiently.

In this guide, we’ll cover everything you need to know about watering forklift batteries, from understanding its importance to following safe and effective methods. Here’s what you’ll learn:

1. Why watering your battery is crucial

2. Best methods and steps for watering

3. The right time to water for maximum performance

Why Is Battery Watering Important?

A typical forklift battery is designed to last around five years, but neglecting proper watering and charging can cut that lifespan in half. Failing to water a battery regularly may reduce its life expectancy by up to 50%, leading to costly replacements that could have been avoided by following simple guidelines. Proper maintenance, including timely watering, is key to getting the most out of your investment.

When Is Watering Necessary?

Forklift batteries, especially those using lead-acid technology, require routine watering to maintain optimal electrolyte levels. The charging and discharging process causes some of the battery’s electrolyte to evaporate, and water replenishment ensures these levels remain ideal.

How often should you water? As a general rule, a forklift operating one shift per day should be watered weekly. However, if your forklift runs multiple shifts or you’re using reconditioned batteries, you may need to water more frequently. Always water the battery after it’s fully charged and has had time to cool.

How to Water a Forklift Battery: Step-by-Step

1. Prioritize Safety First

Before starting, safety is paramount. Wear personal protective equipment (PPE) such as safety goggles, gloves, and aprons to guard against potential acid splashes. There must be an eyewash station within 20 feet.

Additionally, make sure the forklift is turned off, the key is removed, and that you’re working in a well-ventilated area. Avoid any open flames or lit cigarettes, as hydrogen gas can be emitted during charging.

2. Determine When Watering Is Needed

To avoid over-watering or under-watering, you’ll need to check the battery’s electrolyte levels. Here are 2 common methods:

1) Visual Inspection: Regularly inspect the electrolyte levels in each cell. If levels are below the top of the plates, it’s time to add water.

2) Float or Eye Indicators: Some batteries come equipped with built-in indicators that signal when watering is needed. Refer to the manufacturer’s guidelines for specific instructions.

3. Gather the Right Tools

Before watering, make sure you have the following equipment on hand:

1) Watering Jug or Gun: Specialized tools for precise water filling.

2) Distilled or Deionized Water: Tap water can contain impurities that damage the battery, so always use purified water.

3) PPE: Always wear goggles, gloves, long sleeves, and closed-toe shoes for protection.

Optional: A Battery Watering System can automate and streamline the process, ensuring even water distribution and preventing human error.

4. The Watering Process

Manual Method

If you’re manually watering your forklift battery, follow these steps:

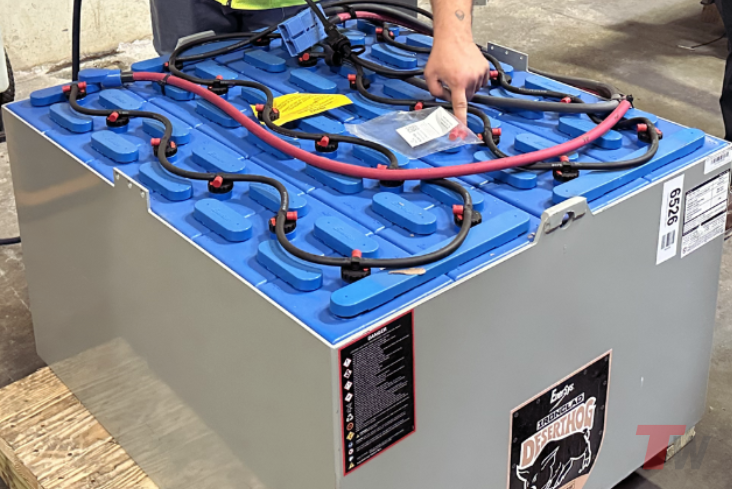

1) Locate the battery’s fill holes or vent caps on the top of each cell.

2) Remove the vent caps, using a tool if needed.

3) Slowly pour distilled water into each cell using a watering jug or gun. Be careful to fill each cell evenly and avoid overfilling.

4) Stop when the electrolyte level reaches the recommended height.

5) Securely replace the vent caps to prevent contamination and evaporation.

Battery Watering Systems (Automated Method)

Automated battery watering systems are a game changer for large operations or businesses seeking to optimize maintenance.

These systems connect directly to the vent caps and automatically fill each cell to the correct level.

All you need to do is attach the system to a water source, and it will handle the rest—ensuring consistent, accurate water levels without the risk of under- or over-watering.

Recap of Key Takeaways

1. Check your water levels at least once a week, and water accordingly

2. Always use Distilled or Deionized Water

3. Always Water Batteries AFTER charging, not before charging.

By establishing a routine and using the right tools, you can extend the life of your forklift batteries, reduce maintenance costs, and improve overall operational efficiency. Whether you choose manual watering or invest in an automated system, staying on top of this crucial maintenance task will keep your equipment performing at its best for years to come.

At Total Warehouse, we provide a range of service and parts programs to guarantee that you get optimal value for your investment, along with the most cost-effective ownership experience. We deliver high-quality products and services at competitive prices, representing products manufactured by Linde, UniCarriers Forklift, Big Joe Manufacturing, and Landoll. We’ve helped countless of businesses across the United States achieve lower maintenance, reduced costs, increased worker satisfaction, and increased economic sustainability. Our team of highly knowledgeable experts can help you make the right decision for your business. Give us a call at 833-868-2500 or contact us online.

About the author:

Julie K has been a key figure in the warehouse industry for over five years, combining with content editorial skills & analytical expertise. She has provided valuable guidance to industry leaders, while her editorial abilities have made complex information accessible to a wider audience. Outside of work, Julie stays at the forefront of warehouse technology, continually expanding her understanding of this dynamic industry.