Let’s face it, warehouse space is at a premium. Every square foot is valuable, and that includes taking advantage of vertical storage. Today, we’re taking a deep dive into a storage solution that can help you achieve just that: push-back racking.

What is Push-Back Racking Systems?

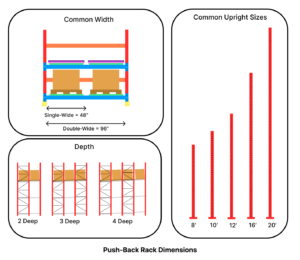

Imagine a system that lets you store pallets two to six deep on either side of an aisle, without sacrificing easy access. That’s the magic of push-back racking. It combines the density of drive-in racking with the single-lane accessibility of selective racking.

Here’s how it works:

- Wheeled carts or rollers line the pick aisle of each lane.

- You place a pallet on the top cart/rollers.

- To add another pallet, the forklift pushes the first pallet back, creating space for the new one.

- This continues until all the carts/rollers are full.

- Unloading is the reverse – pallets are pushed forward for easy retrieval.

Push-Back Racking System Structures: The Good, the Not-So-Good, and the Perfect Fit

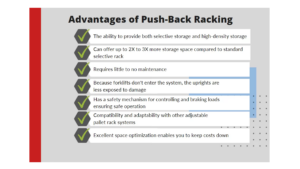

The Good:

- Space Optimization King: Push-back racking can double or even triple your storage capacity compared to standard selective racks.

- Faster Loading & Unloading: Easy access to the front of each lane means faster handling of palletized goods.

- Less Maintenance: The simple design requires minimal upkeep.

- Safety First: Since forklifts don’t enter the racking system, there’s less risk of damage to both the equipment and the structure itself.

- Temperature Resistant: Certain push-back systems are built to withstand cold storage environments.

- Cost-Effective: By maximizing space, you can potentially reduce your overall storage footprint and related costs.

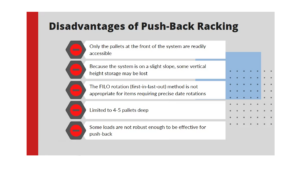

The Not-So-Good:

- Limited Accessibility: Only the pallets at the front are readily available.

- Vertical Space Trade-Off: The slight slope for gravity flow might mean sacrificing some vertical storage height.

- Inventory Rotation: Push-back systems follow a Last-In-First-Out (LIFO) method, so it’s not ideal for items with strict expiration dates.

- Load Limitations: The system relies on the weight of each pallet to push the others forward. So, very lightweight or unstable loads might not be suitable

Are Pushback Storage Racks the Perfect Fit For You?

Push-back racking shines for warehouses with:

✅ High-volume, non-perishable inventory with a long shelf life.

✅ A need for bulk storage of similar products.

✅ Limited order picking requirements (since some pallets might be temporarily inaccessible).

So, are Push-Back Shelving Racks Right for You?

Consider this:

- Do you prioritize maximizing space over easy access to every pallet?

- Do you have a large number of pallets per SKU (ideally between 6 and 30)?

- Are you dealing with items that don’t require strict order picking or specific rotation?

If you answered yes to these questions, then push-back racking could be your warehouse space optimization hero.

Ready to Push the Boundaries of Storage?

At Total Warehouse, we’re experts in helping you find the perfect storage solution for your needs. Push-back racking is just one of the many options we offer. For additional information, please take a look at our article on pallet racking and it’s benefits. Contact us today to discuss your specific requirements and explore how we can help you maximize your warehouse space and efficiency.

We’re confident we can help you find the perfect solution to maximize your space, optimize efficiency, and keep your warehouse running smoothly – all without breaking the bank. Check out our Push Back pallet racking solutions here. Looking to buy today? Don’t hesitate! One of our pallet racking experts would love to share more about our new and used options. Feel free to give us a call at 833-868-2500 or contact us online.