If you are looking for a reliable and efficient reach truck for your warehouse or distribution center, you might be wondering which brand to choose. Crown and Linde are two of the leading manufacturers of reach trucks, offering a range of models and features to suit different applications and environments. But how do they compare in terms of performance, quality, and value?

In this article, we will compare and contrast crown reach trucks and linde reach trucks, based on various criteria such as lift height and capacity, energy efficiency and battery performance, ergonomics and operator comfort, technology and automation, customer service and support, and price and value. We will also provide some recommendations and tips on how to choose the best reach truck for your needs, based on your operational goals and budget.

By the end of this article, you will have a better understanding of the similarities and differences between crown and linde reach trucks, and you will be able to make an informed decision on which brand to buy or rent. Let’s get started!

Key Takeaways

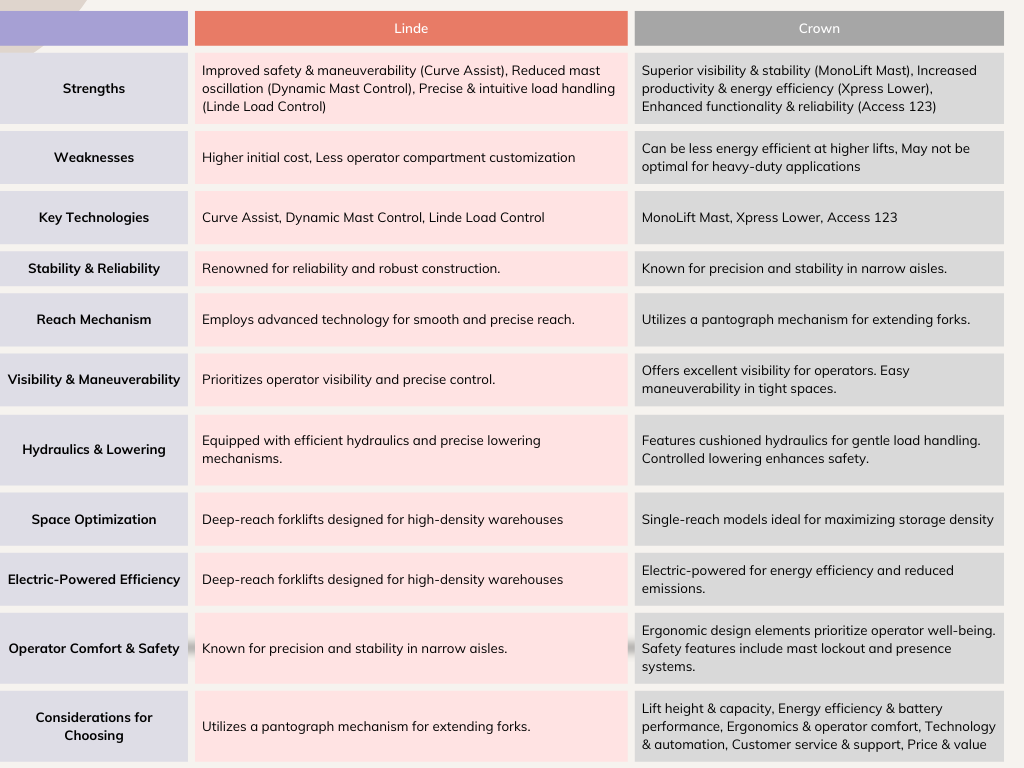

- Crown and Linde are both reputable and innovative manufacturers of reach trucks, offering a variety of models and features to meet different customer needs and preferences.

- Crown reach trucks are known for their MonoLift Mast, which provides superior visibility and stability, their Xpress Lower Technology, which increases productivity and energy efficiency, and their Access 123 Comprehensive System Control, which enhances functionality and reliability.

- Linde reach trucks are known for their Curve Assist, which improves safety and maneuverability, their Dynamic Mast Control, which reduces mast oscillation and sway, and their Linde Load Control, which enables precise and intuitive handling of loads.

- Crown and Linde reach trucks have different strengths and weaknesses in terms of lift height and capacity, energy efficiency and battery performance, ergonomics and operator comfort, technology and automation, customer service and support, and price and value.

- The best reach truck for your needs depends on various factors such as your application and environment, your usage and charging patterns, your operator preferences and feedback, your operational needs and goals, and your budget and investment.

Crown Reach Trucks: Overview and Features

Crown is a global leader in material handling equipment, with over 70 years of experience and innovation. Crown reach trucks are designed to optimize space utilization and productivity in narrow aisle warehouses and distribution centers. Crown offers three main series of reach trucks: the RM/RMD Series MonoLift Mast Reach Truck, the RR/RD Series Reach Truck, and the ESR Series Sit-Down Reach Truck. Each series has different models and configurations to suit different customer needs and preferences.

Here are some key features of Crown reach trucks:

- Lift Heights: Crown’s reach trucks provide breakthrough lift heights, allowing efficient access to high shelves and maximizing vertical storage space.

- Maneuverability: Crown’s nimble design ensures smooth navigation through narrow aisles, making them ideal for high-density warehouses.

- Energy Savings: Crown’s AC-powered reach trucks optimize energy consumption, reducing operational costs and environmental impact.

Some of the unique features and innovations of crown reach trucks are:

- The MonoLift Mast, which is a patented design that eliminates the outer mast channel and provides superior visibility and stability. The MonoLift Mast also allows for greater lift heights and capacities, as well as faster lift and lower speeds.

- The Xpress Lower Technology, which is a patented feature that uses gravity to lower the forks up to twice as fast as conventional systems, without consuming any energy. The Xpress Lower Technology increases productivity and energy efficiency, as well as reduces noise and heat generation.

- The Access 123 Comprehensive System Control, which is a patented system that monitors and controls all aspects of the reach truck’s performance, such as steering, braking, lifting, lowering, traction, and diagnostics. The Access 123 Comprehensive System Control enhances functionality and reliability, as well as simplifies maintenance and troubleshooting.

- The Crown InfoLink Fleet Management System, which is a wireless system that connects the reach trucks to a central database and provides real-time data and insights on the reach truck’s performance, usage, and status. The Crown InfoLink Fleet Management System helps customers optimize their fleet efficiency, safety, and productivity, as well as reduce their operating costs and downtime.

Linde Reach Trucks: Overview and Features

Linde is a global leader in industrial trucks, with over 130 years of experience and innovation. Linde reach trucks are designed to maximize performance and safety in narrow aisle warehouses and distribution centers. Linde offers three main series of reach trucks: the R14X-R16X High Reach Forklift, the R10B-R16B Reach Truck, and the R20-R25 Reach Truck. Each series has different models and configurations to suit different customer needs and preferences.

Here’s a few general reasons why Linde stands out:

- Quality Craftsmanship: Linde’s reputation for durability and reliability precedes it. Their reach trucks withstand rigorous daily use, ensuring longevity and minimal downtime.

- Innovative Features: Linde integrates advanced features like regenerative lowering, which recovers energy during descent, extending battery life and reducing maintenance.

- Operator Comfort: Linde’s ergonomic design prioritizes operator comfort, enhancing productivity during long shifts.

Some of the unique features and innovations of linde reach trucks are:

- The Curve Assist, which is a feature that automatically adjusts the speed and steering angle of the reach truck according to the curve radius and load weight. The Curve Assist improves safety and maneuverability, as well as reduces tire wear and energy consumption.

- The Dynamic Mast Control, which is a feature that uses sensors and actuators to reduce mast oscillation and sway, especially at high lift heights and speeds. The Dynamic Mast Control improves stability and accuracy, as well as reduces cycle times and operator fatigue.

- The Linde Load Control, which is a feature that enables precise and intuitive handling of loads, using ergonomic joysticks and pedals. The Linde Load Control improves productivity and comfort, as well as reduces errors and damage.

- The Linde Connect Fleet Management System, which is a wireless system that connects the reach trucks to a central database and provides real-time data and insights on the reach truck’s performance, usage, and status. The Linde Connect Fleet Management System helps customers optimize their fleet efficiency, safety, and productivity, as well as reduce their operating costs and downtime.

Double Reach Forklifts: Which Brand Excels?

Double reach forklifts, also known as double deep reach trucks, are essential for warehouses with high-density storage needs. These specialized machines allow operators to access two pallets deep within racking systems, maximizing storage capacity. Let’s delve into the specifics of Crown and Linde double reach forklifts:

Crown’s Approach:

- Models: Crown offers a robust lineup of double reach forklifts, including the Crown RR 5700 Series. These machines are designed for versatility, allowing operators to handle both single and double deep storage.

- Customization: Crown’s double reach trucks can be customized to fit various warehouse layouts. Whether you need a universal stance, sidestance, or sit-down reach truck, Crown has options to match your requirements.

- Energy Efficiency: Crown’s AC-powered reach trucks not only enhance productivity but also minimize energy consumption. Efficient regenerative braking systems recover energy during lowering, extending battery life.

Linde’s Expertise:

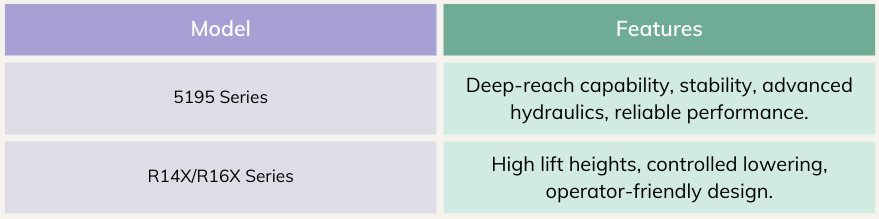

- Models: Linde’s double reach forklifts are part of their R14X and R16X Series. These machines prioritize precision and performance. Linde’s engineering excellence ensures smooth operation even in demanding environments.

- Regenerative Lowering: Linde’s focus on innovation shines through in features like regenerative lowering. As the forks descend, energy is captured and returned to the battery, reducing the need for frequent battery changes.

- Operator Comfort: Linde’s ergonomic design considers operator well-being. Comfortable seating, intuitive controls, and excellent visibility contribute to efficient material handling.

People Also Ask:

- Q1: What is the maximum load capacity of Crown double reach forklifts?

- A: The load capacity varies based on the specific model, but Crown’s double reach forklifts typically handle loads ranging from 3,000 to 4,500 pounds.

- Q2: Are Linde double reach forklifts suitable for narrow aisles?

- A: Absolutely! Linde’s reach trucks are designed for maneuverability in tight spaces. Their compact design allows efficient operation even in narrow aisles.

- Q3: How do double reach forklifts differ from single reach forklifts?

- A: Double reach forklifts have longer forks and are capable of reaching two pallets deep within racking systems. Single reach forklifts handle only one pallet at a time.

Stand-Up Reach Forklifts: Crown’s RC Series vs. Linde’s Stand-Up Models

Ergonomics, Maneuverability, and Attachment Options

Stand-up reach forklifts are ideal for warehouses with limited space and frequent load handling. Let’s compare Crown’s RC Series with Linde’s stand-up reach trucks:

Crown’s RC Series:

- Ergonomics: Crown’s stand-up reach trucks prioritize operator comfort. The RC Series features an adjustable seat, intuitive controls, and excellent visibility. Operators can work efficiently during long shifts.

- Maneuverability: Crown’s stand-up models excel in tight spaces. Whether navigating narrow aisles or loading/unloading at the dock, these trucks offer agility and precision.

- Attachment Options: Crown provides various attachments, such as side shifters and fork positioners, allowing customization based on specific tasks.

Linde’s Stand-Up Models:

- Operator Experience: Linde’s stand-up reach trucks focus on operator experience. The cabin design ensures minimal fatigue, and the controls are intuitive.

- Compact Design: Linde’s compact stand-up models are adept at maneuvering through narrow aisles. They’re suitable for high-density storage areas.

- Advanced Features: Linde integrates advanced features like regenerative braking and automatic speed reduction during cornering.

People Also Ask:

- Q1: What is the turning radius of Crown’s RC Series stand-up reach trucks?

- A: The turning radius varies by model, but Crown’s RC Series typically has a tight turning circle, allowing efficient maneuvering in confined spaces.

- Q2: Do Linde stand-up reach trucks have adjustable controls?

- A: Yes, Linde’s stand-up models feature adjustable controls and ergonomic seating to enhance operator comfort.

- Q3: Which brand offers better visibility in stand-up reach trucks?

- A: Both Crown and Linde prioritize visibility. Operators should choose based on personal preference and specific requirements.

Moving Mast Reach Trucks: Precision Positioning

Understanding Moving Mast Reach Trucks

Moving mast reach trucks, a hallmark of Linde’s innovation, redefine precision positioning. Unlike traditional reach trucks with extendable forks, moving mast reach trucks take a different approach. Here’s what you need to know:

- Mast Movement: Instead of extending the forks, the entire mast moves forward. This unique design allows operators to position pallets with unparalleled accuracy. Whether it’s loading or unloading, moving mast reach trucks excel in tight spaces.

- Advantages:

- Pinpoint Placement: The ability to move the entire mast ensures precise pallet placement, especially in narrow aisles.

- Reduced Risk of Damage: Operators can avoid accidental collisions with racks or adjacent pallets, minimizing product damage.

Warehouse Layouts and Moving Mast Reach Trucks

The adaptability of moving mast reach trucks makes them ideal for various warehouse layouts:

- Irregularly Shaped Storage Areas: Some warehouses have unconventional layouts due to existing structures or space constraints. Moving mast reach trucks seamlessly navigate these irregular shapes, ensuring efficient material handling.

- Changing Configurations: Warehouses often reconfigure their storage areas based on seasonal demands or inventory fluctuations. Moving mast reach trucks accommodate these changes effortlessly. Whether it’s adjusting racking positions or accommodating new storage zones, they provide versatility.

People Also Ask:

- Q1: How does the mast movement work in moving mast reach trucks?

- A: The entire mast, including the forks, moves forward or backward. This allows precise positioning of pallets without extending the forks.

- Q2: Are moving mast reach trucks suitable for high-density storage?

- A: Absolutely! Their ability to navigate tight spaces makes them ideal for maximizing storage density in narrow aisles.

Multidirectional Reach Trucks: Navigating Complexity

The Versatility of Multidirectional Reach Trucks

Multidirectional reach trucks combine features of single-reach and moving mast trucks. Here’s why they matter:

- 360-Degree Movement: Unlike traditional reach trucks that move forward and backward, multidirectional reach trucks can also move sideways. This versatility is invaluable in complex warehouse layouts.

- Applications:

- Handling Irregularly Shaped Loads: Whether it’s long pipes, carpet rolls, or furniture, multidirectional reach trucks handle them with ease.

- Navigating Tight Corners: In warehouses with tight corners or narrow passages, these trucks shine. They eliminate the need for complex maneuvers.

Enhancing Efficiency with Multidirectional Reach Trucks

Warehouse managers appreciate the following benefits:

- Space Optimization: Multidirectional reach trucks allow diagonal movement, utilizing every inch of available space. They’re perfect for maximizing storage capacity.

- Reduced Travel Time: Operators can move directly to their destination without multiple turns. This efficiency translates to faster order picking and replenishment.

People Also Ask:

- Q1: Can multidirectional reach trucks replace traditional forklifts?

- A: While they excel in specific scenarios, multidirectional reach trucks are best used alongside other forklift types. Their unique capabilities complement standard forklifts.

- Q2: What safety features do multidirectional reach trucks have?

- A: These trucks typically include features like stability control, anti-tip mechanisms, and operator presence sensors to enhance safety.

High-Visibility Mast Design: Safety First

The Importance of Mast Visibility

Clear visibility is critical for safe reach truck operation. Both Crown and Linde prioritize mast design to enhance operator safety:

- Crown’s Approach:

- Crown reach trucks feature well-designed masts with minimal obstructions.

- Operators can see the load, rack, and surroundings clearly, reducing the risk of accidents.

- Linde’s Innovation:

- Linde focuses on minimizing blind spots.

- Their mast design ensures operators have an unobstructed view, even at maximum lift heights.

Operator Efficiency and Safety

A high-visibility mast design benefits both productivity and safety:

- Efficiency: Operators can work confidently, knowing they have a clear view of their surroundings. This translates to faster load handling and fewer errors.

- Safety: Accidents due to poor visibility can be costly. By prioritizing mast visibility, both Crown and Linde contribute to a safer warehouse environment.

Hydraulics and Controlled Lowering

Crown Reach Trucks: Cushioned Hydraulics

Crown reach trucks excel in load handling due to their well-engineered hydraulic systems. The cushioned hydraulics ensure smooth lifting and lowering of pallets, minimizing shock to both the operator and the goods. This feature is particularly valuable when handling fragile or sensitive items, such as electronics or glassware.

Moreover, Crown’s controlled lowering mechanism allows precise placement of loads onto shelves or racks. Operators can adjust the descent speed, ensuring safe and accurate positioning. Whether it’s unloading pallets from a truck or stacking inventory in high bays, Crown reach trucks provide optimal control.

Linde Reach Trucks: Precision and Efficiency

Linde’s hydraulic systems are equally impressive. Their reach trucks incorporate advanced technology to optimize load handling. The hydraulics respond swiftly to operator commands, allowing for efficient vertical movement. Linde’s focus on precision ensures that every lift and lower action is predictable and reliable.

Safety-wise, Linde’s controlled lowering feature prevents sudden drops, reducing the risk of load damage or accidents. Operators appreciate the consistent performance, especially during repetitive tasks. Whether you’re retrieving items from elevated racks or replenishing stock, Linde reach trucks deliver consistent results.

Space Optimization and Storage Density

Crown’s Single-Reach Models

Crown’s single-reach reach trucks are designed for space optimization. These compact machines excel in narrow aisles, allowing warehouses to maximize storage density. By reaching only one pallet deep, they efficiently utilize available space without compromising maneuverability. Crown’s innovative MonoLift Mast design further enhances visibility, making it easier for operators to navigate tight corners.

Linde’s Deep-Reach Forklifts

Linde takes a different approach with its deep-reach forklifts. These specialized trucks can reach multiple pallets deep, making them ideal for high-density warehouses. Linde’s R14X and R16X Series offer impressive lift heights while maintaining stability. When you need to access items stored deep within racks, Linde’s deep-reach trucks provide the solution.

Electric-Powered Efficiency

Crown and Linde: Embracing Electric Power

Both Crown and Linde recognize the environmental and economic benefits of electric-powered reach trucks. By eliminating emissions and reducing noise levels, electric reach trucks create a cleaner and safer work environment. Warehouse managers appreciate the cost savings and long-term efficiency of electric fleets.

Crown’s electric reach trucks, including the RR/RD Series, combine power with precision. Their lithium battery-powered models offer extended runtimes and quick charging capabilities. Linde’s commitment to sustainability is evident in their electric reach trucks, such as the Linde 5195 Series. These trucks balance power, efficiency, and eco-friendliness seamlessly.

Operator Comfort and Safety

Ergonomics and Safety in Crown and Linde Reach Trucks

Both Crown and Linde prioritize operator well-being, recognizing that comfortable and safe working conditions lead to better productivity and job satisfaction.

Crown’s Operator-Centric Design

Crown reach trucks are engineered with the operator in mind. Here’s how they enhance comfort and safety:

- Ergonomic Seating and Controls: Crown’s spacious cabins feature adjustable seats, lumbar support, and intuitive controls. Operators can fine-tune their seating position for extended shifts, reducing fatigue and discomfort.

- Clear Sightlines: Crown’s MonoLift Mast design ensures excellent visibility. Operators can see the forks, load, and surroundings clearly, minimizing the risk of collisions or accidents.

- Operator Presence System: Crown reach trucks are equipped with an operator presence sensor. If the operator leaves the seat, the truck automatically engages the parking brake, preventing unintended movement.

- Mast Lockout: During maintenance or service, Crown’s mast lockout feature ensures that the forks remain stationary, enhancing technician safety.

Linde’s Operator-Focused Approach

Linde’s reach trucks also prioritize operator comfort and safety:

- Spacious Cabins: Linde’s cabins provide ample room for operators to move comfortably. Adjustable seats and ergonomic controls contribute to a pleasant working environment.

- Visibility Enhancements: Linde’s panoramic view mast design maximizes visibility. Operators can navigate tight spaces confidently, reducing the risk of accidents.

- Operator Presence Detection: Linde’s reach trucks feature an operator presence detection system. If the operator leaves the seat, the truck automatically stops, preventing unauthorized use.

- Safety Interlocks: Linde incorporates safety interlocks to prevent unsafe actions. For example, the truck won’t lift the forks if the operator is not seated correctly.

Conclusion and Recommendations

Choosing Between Crown and Linde Reach Trucks

In the battle of Crown vs. Linde, there’s no clear winner—it depends on your specific warehouse needs. Here are our recommendations:

-

Crown Reach Trucks:

- Ideal for warehouses with narrow aisles and high-density storage.

- Consider Crown if you prioritize precision, cushioned hydraulics, and single-reach models.

- Explore the Crown RM/RMD Series for exceptional performance.

-

Linde Reach Trucks:

- Opt for Linde if reliability, stability, and deep-reach capabilities are crucial.

- The Linde 5195 Series offers robust construction and efficient hydraulics.

- Linde’s reputation for durability makes it a solid choice for long-term use.

Additional Considerations

- Budget: Consider upfront costs, maintenance, and total cost of ownership.

- Training: Ensure operators receive proper training for safe and efficient use.

- Application: Evaluate your warehouse layout, load types, and operational requirements.

Remember, the right reach truck can transform your warehouse operations. Whether you’re stacking pallets, retrieving inventory, or optimizing storage, Crown and Linde have solutions tailored to your needs.

Tables for Quick Reference

Crown Reach Truck Models

Linde Reach Truck Models

In Summary

Choosing between Crown and Linde reach trucks involves weighing factors like stability, hydraulics, visibility, and operator comfort. Assess your warehouse requirements, explore detailed specifications, and make an informed decision. Whichever brand you choose, prioritize safety, efficiency, and long-term value. 🚚🏢🔧