Key Takeaways

Introduction to Industrial Pallet Rack Systems

Industrial pallet racking systems are the backbone of efficient warehouse operations. These systems are designed to maximize storage space while ensuring easy access to inventory. Pallet racking involves storing goods on pallets, which can be easily retrieved using forklifts, making it an essential component of modern warehousing.

An efficient racking system can significantly improve a warehouse’s productivity by optimizing the use of vertical space. The right pallet racking system not only enhances storage capacity but also improves the safety and organization of the warehouse. Having hands-on experience with various racking systems, I’ve seen firsthand how a well-designed warehouse racking systems can transform operations, reducing retrieval times and increasing overall efficiency.

The Evolution of Warehouse Racking: From Traditional to Modern Systems

Warehouse racking has evolved considerably over the years. Initially, warehouses relied on simple shelving systems, which were limited in their capacity and accessibility. As industrial needs grew, so did the complexity of racking systems. The introduction of forklifts revolutionized warehouse storage, enabling higher and deeper racks.

Key Milestones in Racking System Development

- Early Shelving Systems: Basic storage solutions with limited capacity.

- Introduction of Pallet Racking: Facilitated by the advent of forklifts.

- Advancements in Materials: Transition from wood to steel and other durable materials.

- Innovative Designs: Development of various racking types like selective, drive-in, and cantilever.

Today’s modern racking systems incorporate advanced materials and designs, offering enhanced durability and versatility. The integration of automation and smart technology is the latest trend, paving the way for even more efficient warehouse operations.

Insightful Analysis: Modern racking systems are not just about storage; they’re about smart storage. Incorporating technology such as Warehouse Management Systems (WMS) can further streamline operations, ensuring real-time inventory tracking and efficient space utilization.

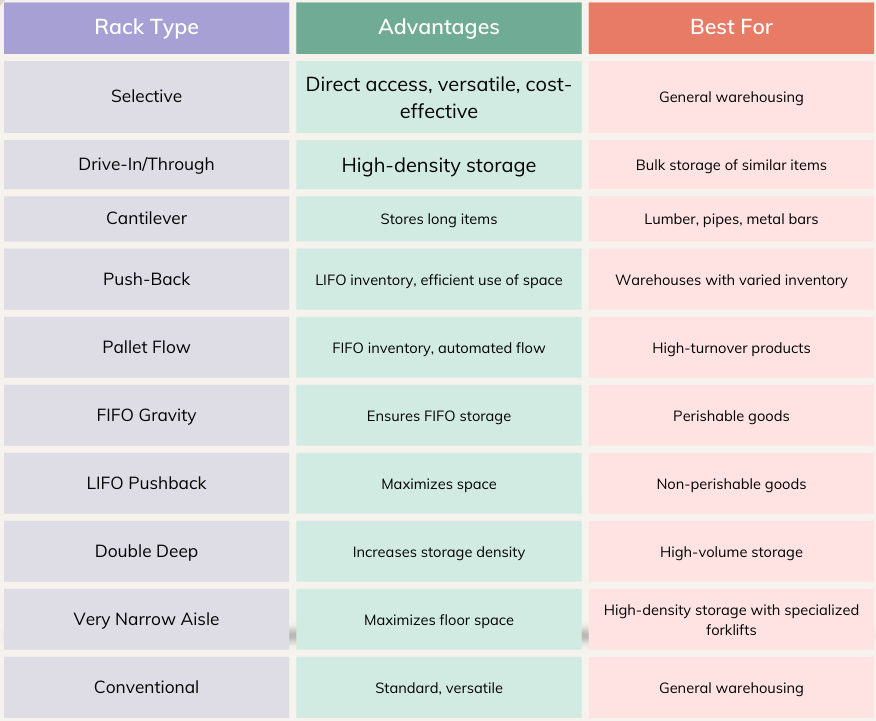

Understanding the Different Warehouse Pallet Racking Types

Selecting the right type of pallet racking system is crucial for optimizing warehouse space and operations. Here’s a detailed look at various types of industrial pallet racks:

Selective Pallet Racking

- Most common type.

- Allows direct access to each pallet.

- Versatile and cost-effective.

Drive-In and Drive-Through Racking

- Drive-In Racking: Forklifts enter the rack structure to access pallets from the same entry point.

- Drive-Through Racking: Forklifts can access from both ends, allowing for first-in, first-out (FIFO) inventory management.

- Ideal for high-density storage.

Cantilever Racking

- Designed for long, bulky items like pipes and lumber.

- Consists of a series of arms extended from a central column.

- Highly adaptable for different sizes and lengths.

Push-Back Racking

- Uses a system of nested carts.

- Pallets are loaded from the front and pushed back.

- Efficient for last-in, first-out (LIFO) inventory.

Pallet Flow Racking

- Uses a gravity-driven system.

- Pallets are loaded from one end and flow to the other.

- Ideal for FIFO inventory.

Additional Pallet Rack Types

- FIFO Gravity Racks: Ensure first-in, first-out storage using gravity-fed systems.

- LIFO Pushback Racks: Allow last-in, first-out storage with nested carts.

- Double Deep Adjustable Pallet Rack: Increases storage density by storing two pallets deep.

- Very Narrow Aisle Pallet Rack: Maximizes storage space by reducing aisle width, requires specialized forklifts.

- Conventional Pallet Racks: Standard racking systems used for a variety of goods.

Table: Comparison of Types of Rackings

FAQs

Q: What is the best pallet racking system for high-density storage? A: Drive-in and drive-through racking systems are ideal for high-density storage, allowing for maximum use of space.

Q: How do I decide between FIFO and LIFO racking systems? A: Choose FIFO systems for perishable goods that require strict rotation and LIFO systems for non-perishable items where the last-in products can be accessed first.

Key Components and Accessories for Pallet Racking Systems

Understanding the components and accessories of pallet racking systems is essential for ensuring their proper function and safety.

Main Components

- Beams: Horizontal supports that hold the pallets.

- Frames: Vertical structures that support the beams.

- Decking: Surface that holds the pallets, available in wire or solid options.

Safety Accessories

- Wire Decking: Enhances safety by providing a stable surface.

- Column Protectors: Prevent damage to the vertical columns from forklifts.

- Pallet Supports: Provide additional support for pallets, preventing them from falling.

Load Capacity and Stability

It’s crucial to consider the load capacity and stability of your racking system. Overloading can lead to accidents and damage, so always adhere to manufacturer guidelines and regularly inspect your racking for any signs of wear and tear.

Expert Opinion: Investing in quality accessories and adhering to safety protocols not only prolongs the life of your racking system but also ensures a safer working environment.

List: Essential Safety Accessories

- Wire Decking

- Column Protectors

- Pallet Supports

- Safety Netting

- Load Signs

FAQs

Q: How often should I inspect my pallet racking system? A: Regular inspections should be conducted at least monthly to ensure the integrity of the system and to identify any potential issues early.

Q: What are the most important accessories for pallet racking safety? A: Wire decking, column protectors, and pallet supports are among the most important accessories to ensure safety.

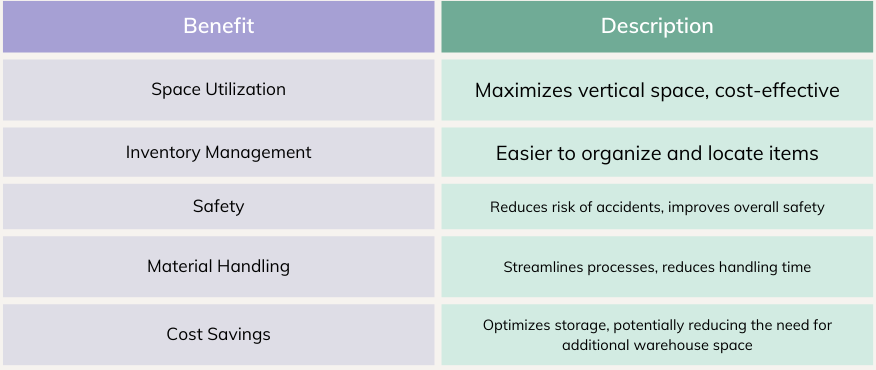

Benefits of Implementing a Racked Warehouse System

Implementing a warehouse pallet racking system offers numerous benefits that enhance the overall efficiency and safety of warehouse operations.

Improved Space Utilization and Efficiency

A well-designed racking system maximizes vertical space, allowing for more storage without expanding the warehouse footprint. This efficient use of space can lead to significant cost savings.

Enhanced Inventory Management and Accessibility

With organized pallet racking, inventory management becomes more straightforward. Items are easier to locate, reducing retrieval times and improving overall productivity. In my experience, having a structured racking system has drastically cut down on the time spent searching for products, leading to faster order fulfillment.

Increased Safety and Reduction in Material Handling Time

Safety is paramount in any warehouse. Pallet racking systems, when properly installed and maintained, can reduce the risk of accidents. Additionally, they streamline material handling, as forklifts can easily access and transport pallets, reducing handling time.

Table: Benefits of Racked Warehouse Systems

FAQs

Q: What is the main advantage of using pallet racking systems? A: The primary advantage is improved space utilization, allowing for more efficient storage and better organization of inventory.

A: Properly installed and maintained racking systems reduce the risk of accidents by providing stable and secure storage, preventing the collapse of racks, and minimizing the chances of items falling from heights. Additionally, organized racking systems reduce clutter, improving overall workflow and reducing trip hazards for warehouse personnel.

Designing an Efficient Industrial Pallet Rack Layout

Designing an efficient layout for your industrial pallet racking system is critical for optimizing storage and ensuring smooth operations.

Assessing Warehouse Space and Ceiling Height

Before installing any racking system, it’s essential to assess the available warehouse space and ceiling height. This assessment will determine the type and configuration of the racking system that best suits your needs.

Determining Load Requirements and Pallet Sizes

Understanding the weight and size of the loads you need to store is crucial. This information helps in selecting the appropriate racking system and ensuring that it can safely support your inventory.

Optimizing Aisle Width and Forklift Accessibility

The width of the aisles should be optimized for the type of forklifts used in your warehouse. Narrow aisles can maximize storage space, but they require specialized narrow aisle forklifts. In my experience, optimizing aisle width has been a game-changer, significantly improving the maneuverability and speed of forklifts.

List: Key Considerations for Racking Layout

- Assess warehouse dimensions

- Determine load capacities

- Select appropriate racking type

- Optimize aisle width

- Ensure forklift compatibility

FAQs

Q: How do I determine the best layout for my warehouse? A: Start by assessing your warehouse space and ceiling height, then determine your load requirements and select a racking system that maximizes space while ensuring easy access for forklifts.

Q: What are the benefits of optimizing aisle width? A: Optimizing aisle width improves forklift accessibility and maneuverability, leading to faster and more efficient material handling.

Installation and Maintenance of Pallet Racking Systems

Proper installation and regular maintenance of pallet racking systems are vital for their longevity and safety.

Step-by-Step Installation Process

- Site Preparation: Clear the installation area and ensure the floor is level.

- Assemble Frames and Beams: Follow the manufacturer’s instructions for assembling the frames and beams.

- Anchor Frames: Secure the frames to the floor to ensure stability.

- Install Decking and Accessories: Add wire decking, pallet supports, and other accessories as needed.

- Inspect and Test: Conduct a thorough inspection and test the system for stability and load capacity.

Regular Maintenance Practices

- Inspect for Damage: Regularly check for any signs of damage or wear.

- Tighten Bolts and Fasteners: Ensure all bolts and fasteners are secure.

- Clean Regularly: Keep the racking system clean and free from debris.

- Load Checks: Regularly check that the load capacities are not being exceeded.

Common Issues and Troubleshooting Tips

- Bent Frames or Beams: Replace immediately to prevent collapse.

- Loose Bolts: Tighten to maintain stability.

- Overloading: Ensure loads do not exceed the recommended capacity.

Practical Tip: Regular maintenance is not just about safety; it’s about preserving your investment. Routine checks can prevent costly repairs and downtime.

FAQs

Q: How often should pallet racking systems be inspected? A: Inspections should be conducted monthly, with a more thorough review every six months.

Q: What are common maintenance practices for pallet racking? A: Regular inspections, tightening of bolts, cleaning, and load capacity checks are essential maintenance practices.

Safety Regulations and Standards

OSHA Guidelines and Industry Standards

Compliance with safety regulations is crucial for maintaining a safe and efficient warehouse environment. The Occupational Safety and Health Administration (OSHA) sets forth guidelines that are essential for ensuring the safety of pallet racking systems in warehouses. Key OSHA regulations include proper installation, regular maintenance, and adherence to load capacities to prevent accidents.

Best Practices for Ensuring Compliance

- Regular Inspections: Conduct thorough inspections of racking systems regularly to identify and rectify any damages or potential hazards.

- Proper Load Management: Ensure that the weight of the stored goods does not exceed the load capacity of the racking system. Use load signs to communicate weight limits clearly.

- Secure Installation: Follow manufacturer guidelines for the installation of racking systems, ensuring that all components are securely anchored and assembled.

- Use of Safety Accessories: Implement safety accessories such as wire decking, column protectors, and safety netting to enhance stability and safety.

- Documentation: Maintain detailed records of inspections, maintenance, and employee training to demonstrate compliance with safety standards.

Training and Certification for Warehouse Staff

Proper training and certification are vital for warehouse staff to operate safely and efficiently. Employees should be trained on the following aspects:

- Safety Protocols: Understanding and adhering to safety procedures for handling and storing goods.

- Equipment Use: Proper use of forklifts and other material handling equipment.

- Emergency Procedures: Knowledge of emergency protocols in case of accidents or equipment failures.

- Inspection and Maintenance: Training on how to conduct regular inspections and perform basic maintenance on racking systems.

Certification programs can further enhance staff expertise, ensuring that they are well-versed in the latest safety standards and practices.

Case Studies: Successful Implementation of Pallet Racking Systems

Real-World Examples from Various Industries

Implementing pallet racking systems can yield significant benefits across different industries. Here are a few examples:

Example 1: Automotive Parts Warehouse

Challenge: An automotive parts warehouse faced issues with space utilization and inventory management. Solution: Implemented selective pallet racking to organize parts by category and improve accessibility. Measurable Benefits:

- Improved space utilization by 30%.

- Reduced retrieval time by 25%.

- Enhanced inventory accuracy through better organization.

Example 2: Food and Beverage Distribution Center

Challenge: A food and beverage distribution center needed to ensure compliance with FIFO inventory management for perishable goods. Solution: Installed pallet flow racking systems to facilitate first-in, first-out inventory rotation. Measurable Benefits:

- Reduced spoilage by 15%.

- Streamlined loading and unloading processes.

- Increased storage capacity by 20%.

Example 3: E-Commerce Fulfillment Center

Challenge: An e-commerce fulfillment center struggled with fast order turnaround times and efficient space use. Solution: Adopted very narrow aisle pallet racking to maximize storage density and improve picking efficiency. Measurable Benefits:

- Increased order fulfillment speed by 40%.

- Optimized floor space usage.

- Improved worker productivity.

Challenges Faced and Solutions Implemented

Each case study highlights unique challenges and the tailored solutions implemented to overcome them. Common challenges include space constraints, inventory management issues, and compliance with safety standards. Solutions often involve selecting the appropriate type of pallet racking system, optimizing layout design, and enhancing safety measures.

Future Trends in Industrial Pallet Racking and Warehouse Management

Automation and Smart Racking Systems

The future of warehouse management lies in automation and the integration of smart technologies. Automated pallet racking systems, such as automated storage and retrieval systems (AS/RS), enhance efficiency by automating the retrieval and storage of goods.

Integration with Warehouse Management Software (WMS)

Integrating pallet racking systems with Warehouse Management Software (WMS) offers several advantages:

- Real-Time Inventory Tracking: Provides accurate and up-to-date information on inventory levels and locations.

- Improved Accuracy: Reduces errors in order picking and inventory management.

- Enhanced Efficiency: Streamlines warehouse operations, reducing labor costs and improving productivity.

Expert Opinion: In my experience, integrating WMS with pallet racking systems has revolutionized inventory management, making it possible to track products in real-time and optimize warehouse operations seamlessly.

Sustainable and Eco-Friendly Racking Solutions

Sustainability is becoming increasingly important in warehouse management. Eco-friendly racking solutions focus on reducing the environmental impact of storage systems. Key trends include:

- Recyclable Materials: Using racking systems made from recyclable materials to reduce waste.

- Energy-Efficient Lighting: Implementing LED lighting and motion sensors to reduce energy consumption.

- Space Optimization: Designing racking systems that maximize storage space, reducing the need for warehouse expansion and minimizing environmental impact.

Insightful Analysis: The shift towards sustainable racking solutions not only benefits the environment but also offers cost savings through reduced energy consumption and improved space utilization.

By understanding and implementing the best practices for safety regulations, successfully deploying pallet racking systems, and embracing future trends, warehouses can significantly enhance their efficiency, safety, and sustainability.

By ensuring that your warehouse racking is optimized with the right pallet racking systems, components, and maintenance practices, you can enhance your operational efficiency, safety, and overall productivity.