Get to Know Electric Battery Systems

Q: What’s the Difference Between Lithium, Lead Acid, TPPL, Flat Plate, and Tubular Batteries for Forklifts?

A: When it comes to powering your forklifts, not all batteries are created equal. The right choice can boost productivity, reduce downtime, and even save money long-term. Here’s a breakdown of the main differences, advantages, and best uses of the top forklift battery types:

1. Lithium-Ion (Li-ion)

Best for: High-efficiency operations, multi-shift use, fast turnaround.

Lithium-Ion (Li-ion) batteries are ideal for high-efficiency, multi-shift operations that require quick turnaround. They offer fast charging—often within 1–2 hours—and support opportunity charging, which means operators can plug in during breaks without damaging the battery. They require zero maintenance, have a long lifespan of over 3,000 cycles, and are sealed for safe, clean operation. While the upfront cost is higher, lithium batteries offer a lower total cost of ownership over time.

2. Lead Acid (Flooded)

Best for: Budget-conscious, single-shift operations with downtime for charging.

Lead Acid (Flooded) batteries are a more budget-friendly option, best suited for single-shift operations with ample downtime for charging. They are a proven, widely available technology with a lower initial investment. However, they do require regular maintenance such as watering, have long charge times (8+ hours), and need a well-ventilated charging area due to the release of gases during charging.

3. TPPL (Thin Plate Pure Lead)

Best for: Operations needing some of lithium’s benefits but at a lower price point.

TPPL (Thin Plate Pure Lead) batteries are great for operations looking for some of the benefits of lithium without the higher price tag. These batteries are maintenance-free, charge faster than traditional lead acid, and offer more cycles than standard flooded batteries. They also allow for partial charging, making them more flexible. That said, they are more expensive than traditional lead acid and don’t last quite as long as lithium batteries.

4. Flat Plate (Type of Lead Acid)

Best for: Light to medium duty operations.

Flat Plate batteries, a type of lead acid, are well-suited for light to medium-duty operations. They offer a lower upfront cost and perform reliably in consistent, low-demand environments. However, they have a shorter lifespan compared to other battery types and are less efficient under heavier loads.

5. Tubular Plate (Type of Lead Acid)

Best for: High-duty cycles and heavier equipment.

Tubular Plate batteries, also a type of lead acid, are built for heavy-duty cycles and deep discharges, making them ideal for demanding applications such as high-capacity forklifts or continuous use. They offer a longer lifespan than flat plate batteries and are more durable under tough conditions. They do, however, come at a higher cost and still require routine maintenance.

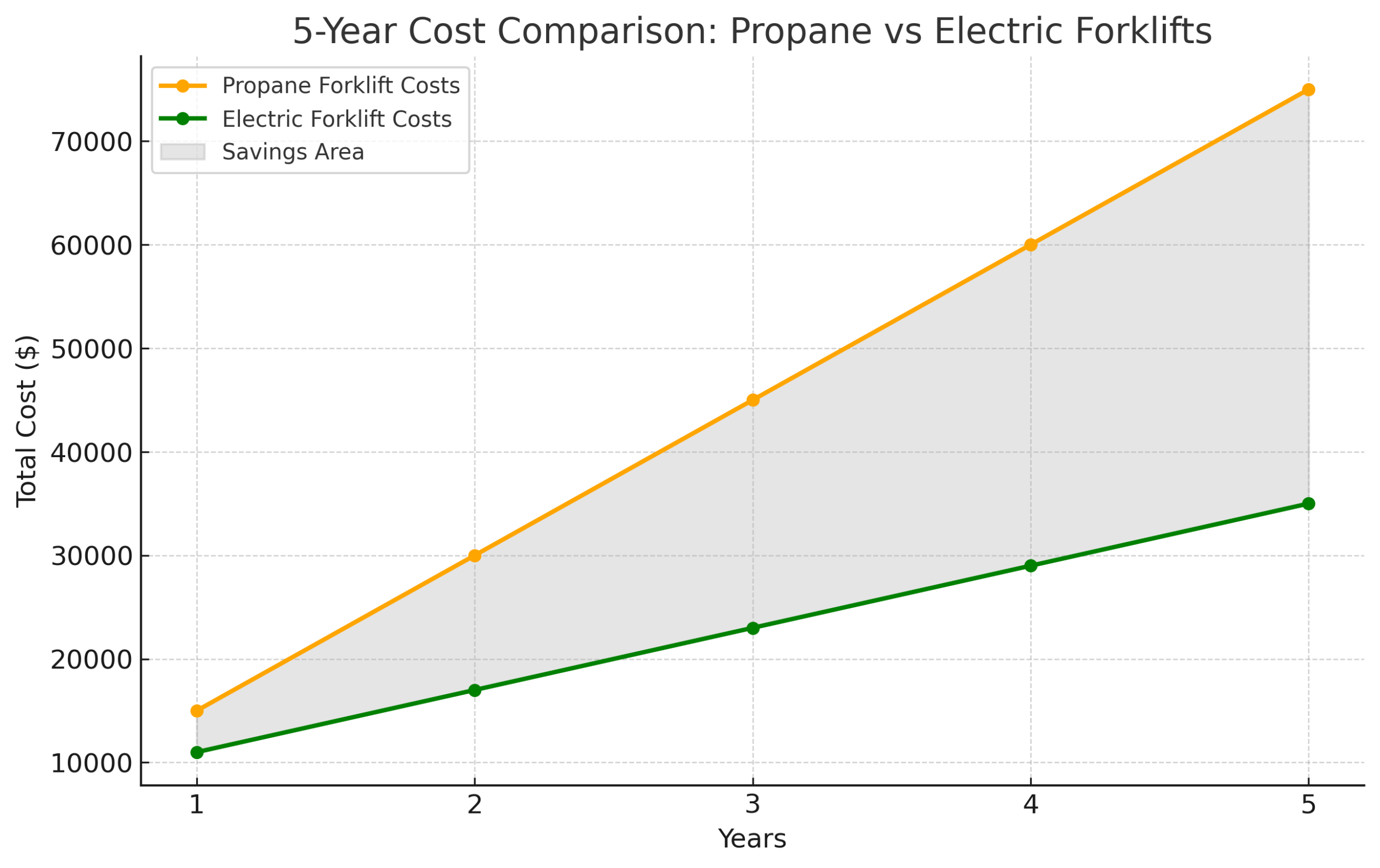

Q: How Can I Save Money by Switching from Propane to Electric Forklift Batteries?

A: Switching from propane-powered forklifts to electric battery-powered forklifts can lead to significant cost savings—not just in fuel, but in maintenance, efficiency, and total cost of ownership. Here’s how:

1. Lower Fuel Costs

Propane costs 2-3x more per hour of use compared to electricity. Over time, the difference adds up—especially in multi-shift operations.

2. Less Maintenance

Electric forklifts have fewer moving parts, no engine, no transmission, and no exhaust systems to worry about. That means less downtime and fewer repair bills.

3. Charging Is Cheaper Than Refueling

Electric batteries can be charged during off-peak hours to reduce electricity costs even more—no need for propane tank swaps or storage.

4. Longer Lifespan

Lithium or TPPL batteries can last 2-3x longer than internal combustion components, providing lower lifetime costs.

5. Tax Incentives & Environmental Credits

Some regions offer rebates, grants, or tax deductions for going electric, and being green can also help with ESG goals or customer expectations.

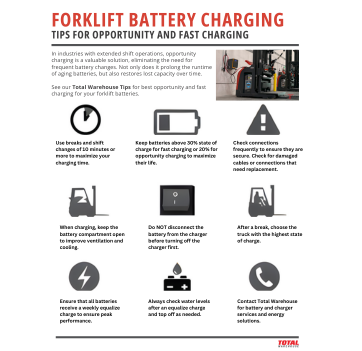

Q: Is Charging Forklift Batteries Complicated or Costly?

A: Not at all—charging is easier than it looks, and Total Warehouse makes it simple.

Many businesses worry that switching to electric means expensive infrastructure or complex charging routines, but the reality is the opposite. Modern chargers are compact, easy to install, and can be placed right where you need them—no dedicated room required. Charging can happen during breaks or shift changes, with smart systems that prevent overcharging and reduce downtime.

Best of all, Total Warehouse experts handle everything—from layout planning and installation to staff training and support—so you don’t have to guess or go it alone. With lower fuel costs, less maintenance, and easy day-to-day use, electric forklifts are a smart move—and charging them is one of the easiest parts.

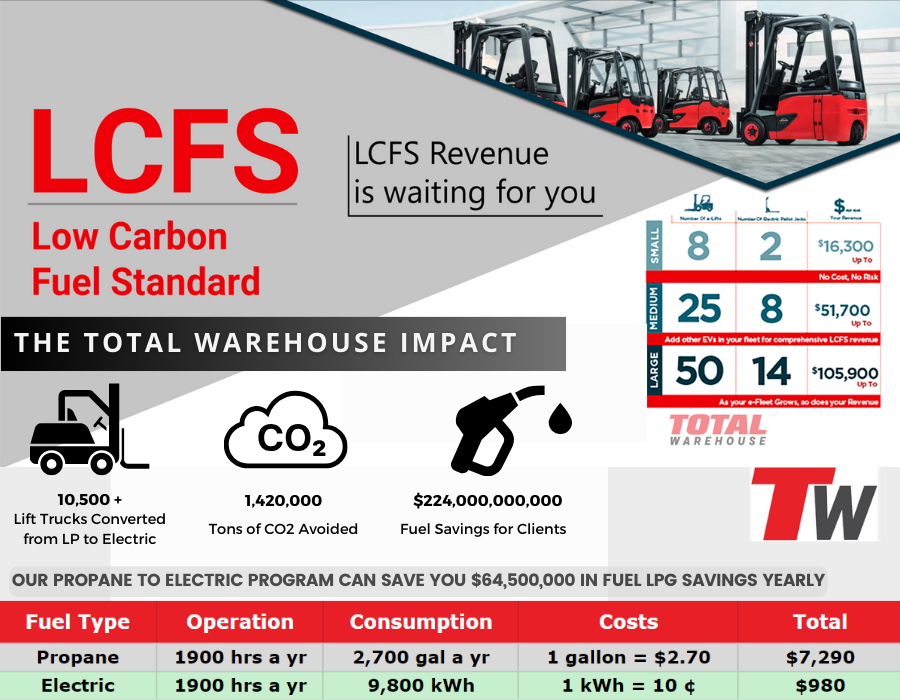

Q: What Is the LCFS Program and How Can It Save My Business Money?

A: The LCFS Program (Low Carbon Fuel Standard), managed by CARB (California Air Resources Board), provides cash incentives for companies that switch from propane (LPG) to electric-powered equipment, such as forklifts. By participating, your facility can earn tens of thousands of dollars per year through LCFS credits, making electric forklifts more affordable while also reducing your carbon footprint.

How Much Can I Save?

Through our Propane to Electric Conversion Program, Total Warehouse customers have the potential to save millions annually in fuel costs. One program example shows a $64.5 million total savings in fuel LPG.

Why Make the Switch?

-

Earn rebates and credits from the state

-

Save significantly on fuel costs

-

Improve sustainability and reduce emissions

-

Get expert support from Total Warehouse to calculate and claim your savings

How Do I Get Started?

Click to calculate your savings from LPG to electric or contact Total Warehouse to see how much your facility could earn through LCFS credits.

Learn More: Zero-Emission Forklift Regulation – Fleet Impact?

Q: How Can Total Warehouse Help Me Transition to Electric Forklifts and Maximize Incentives?

A: At Total Warehouse, we make the switch to electric easy, smart, and rewarding. Here’s how we help you every step of the way:

Expert Guidance: We don’t just sell forklifts—we analyze your operation, recommend the best electric models for your workflow, and ensure you’re fully CARB-compliant from day one.

Zero-Emission Solutions: All our electric forklifts meet strict emissions standards and can be custom-fit to your existing fleet. Whether you’re scaling up or just starting out, we have options that work.

Incentive Navigation: Rebates? Tax credits? LCFS rewards? We’ll help you claim every dollar you’re eligible for, making the investment in electric even more cost-effective.

Seamless Transition: From removing outdated propane units to upgrading your charging infrastructure, we offer full-service support so you can modernize with zero stress.

Ready to future-proof your fleet? Let Total Warehouse help you save money, meet regulations, and power a greener operation. Request A Free Consultation Today!

Li-Ion Forklift Batteries

Complete Energy Solution

Explore Our Lithium Ion Forklift Battery Energy Solutions:

- Linde KBS Lithium Batteries & Chargers

- EnerSys Batteries & Chargers

- Triathlon Batteries & Chargers

- Electric Forklifts

- Electric Order Pickers

- Electric Pallet Jacks

- Electric Walkie Riders

- Electric Reaches

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.