KEY FEATURES

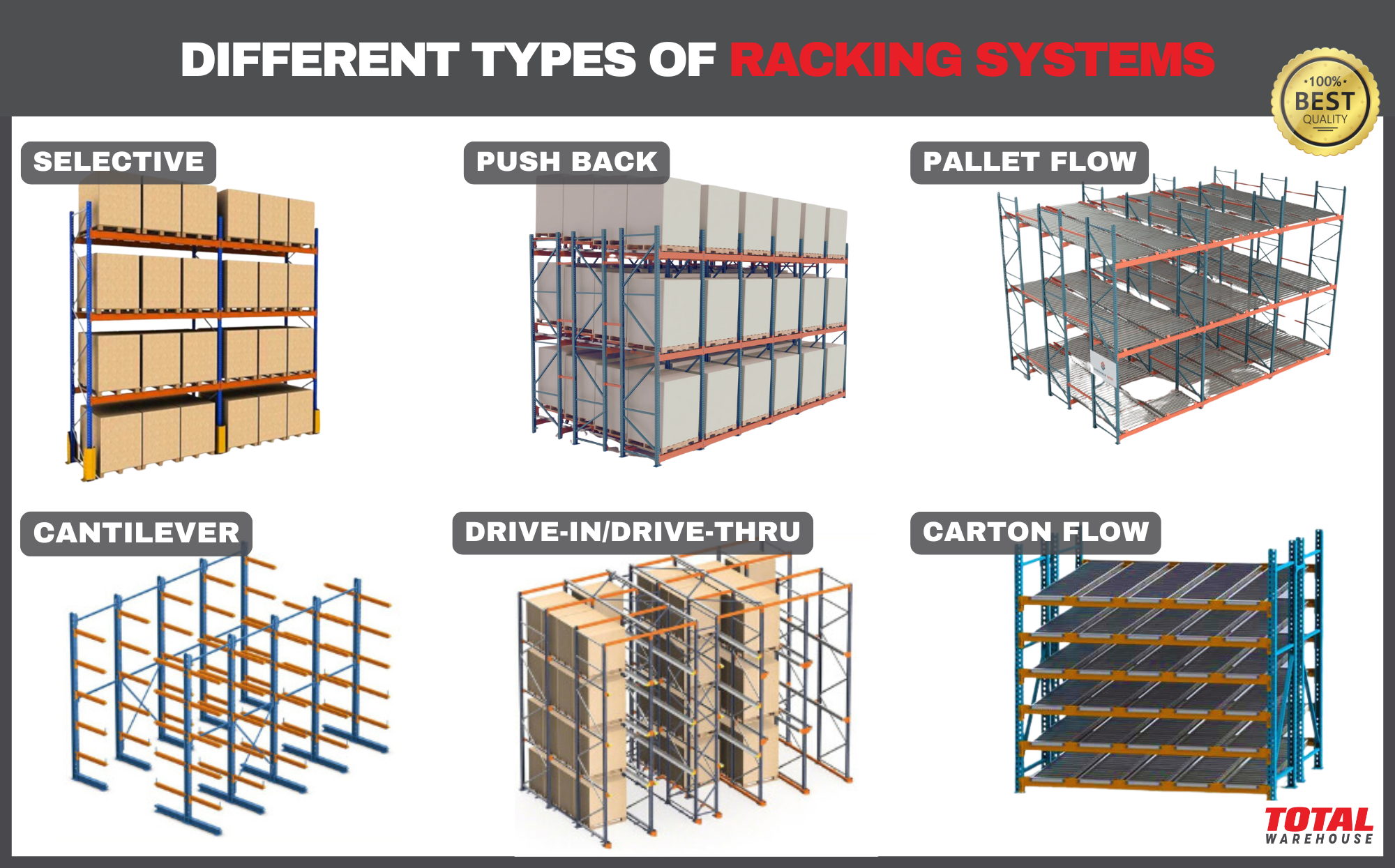

Selecting The Best Pallet Rack

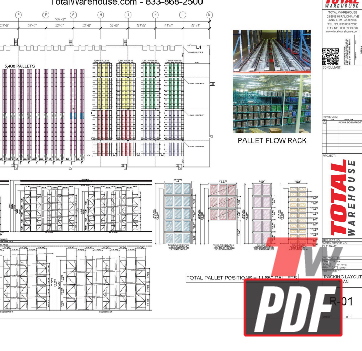

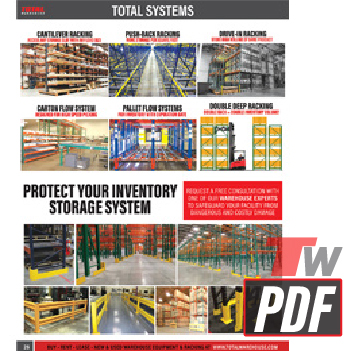

Choosing the right pallet racking configuration is essential to meet your storage needs. With various options available, it’s important to select the system that best fits your space and inventory requirements. From drive-in racks to push-back systems, understanding your needs can help you optimize your storage efficiency.

Rack Examples Include: Interlake Old Style Tear Drop, Kingway Tear Drop, USP Tear Drop, Speed Rack Tear Drop, Mecalux Tear Drop, Lyon Metal Tear Drop, Interlake New Style Tear Drop, Space Rack Tear Drop, Bull Dog Tear Drop, Highline, Buckley, Unarco T-Bolt, Penco Slotted, Redi Rack, Frick Gallagher, Keystone, Palletier Old Style, Speed Rack, Husky Slotted, Buckley Master, Republic Keystone, Triple A, Cantennial, EMI Arrowstar, Amerilock, Prest Tear Drop, Palletier New Style, Sammons, EMI, Artco, Unarco 2, Ace Rack, Hiline, Prest Web Style, Strudi Built, Ridge U Rack, Burtman, Palmershile, Speed Rack, Structural Rack, Amerack and MI-Rack

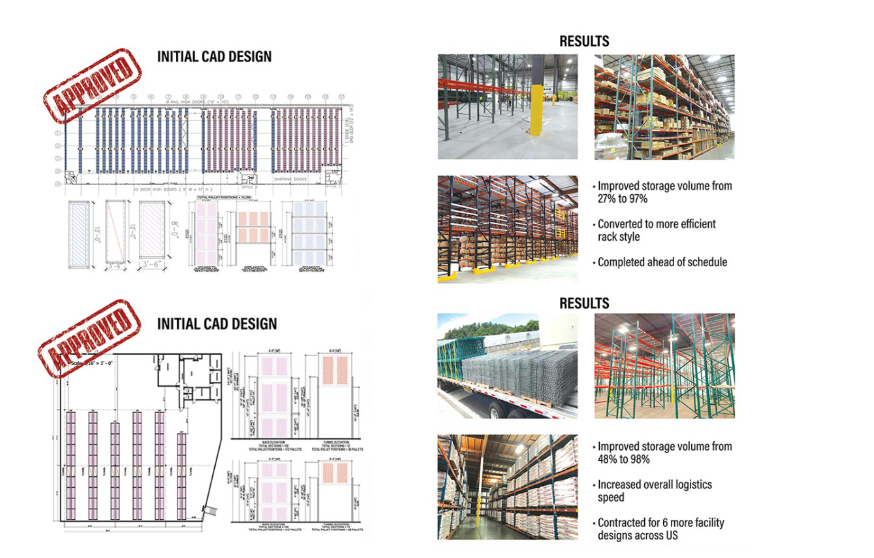

Maximize Efficiency with Custom Solutions

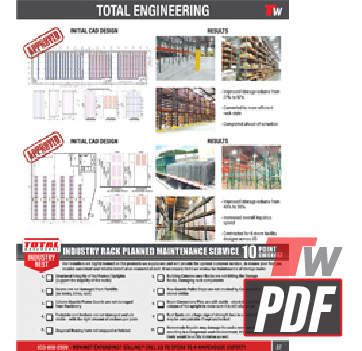

By thoroughly evaluating your inventory and processing requirements, methods, and objectives, we’ll design the most efficient configuration of storage and processing systems tailored to maximize your space, equipment, and labor resources.

Total Warehouse Engineering & Design Experts offers:

- Analysis of inventory load requirements

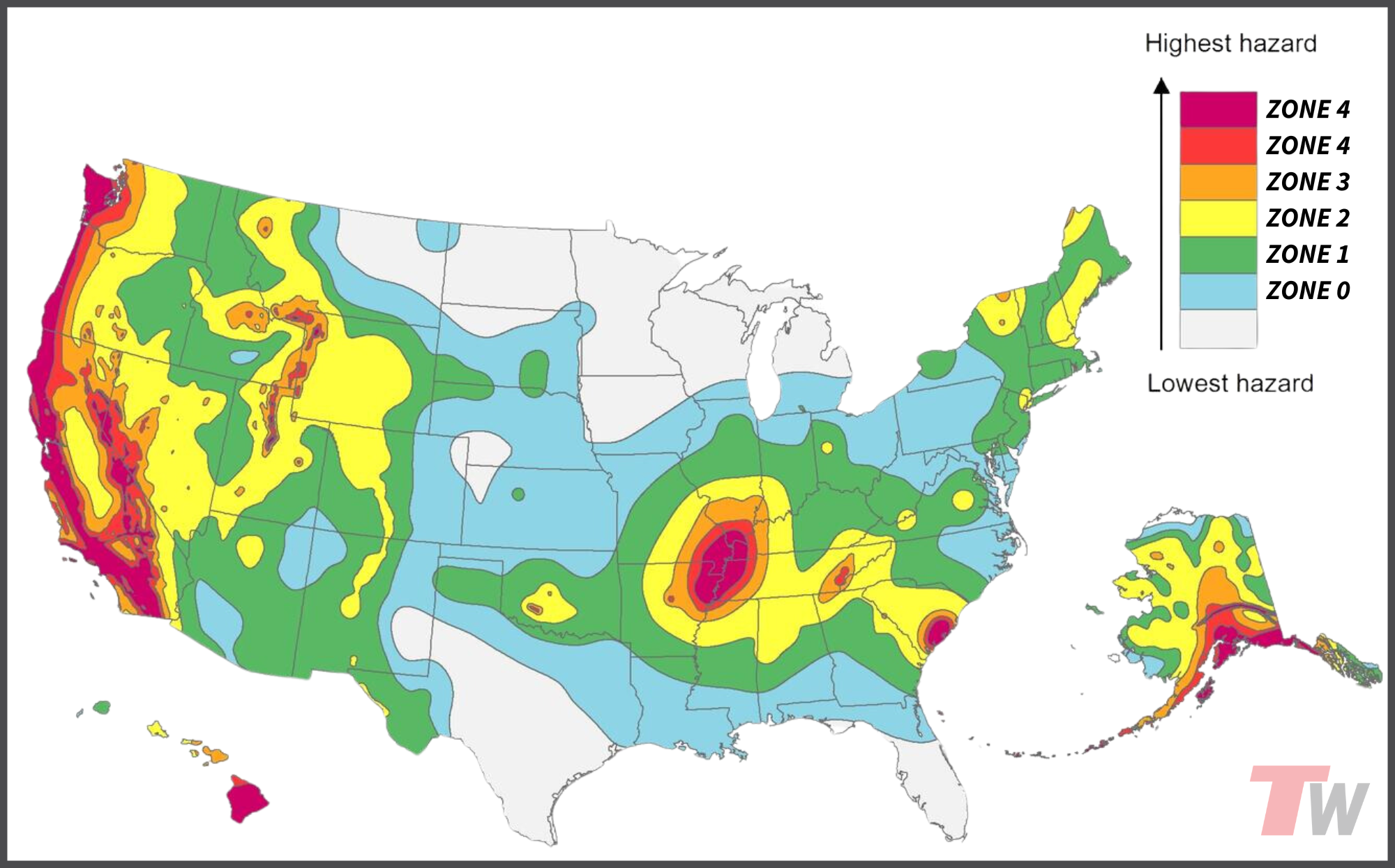

- Determined environmental considerations like seismic activity & warehouse conditions

- Understanding of facility design and equipment limitations

- Development of practical storage and processing solutions

- Provision of advice on equipment and automation tools, if necessary

Tailored Solutions with TW Engineers

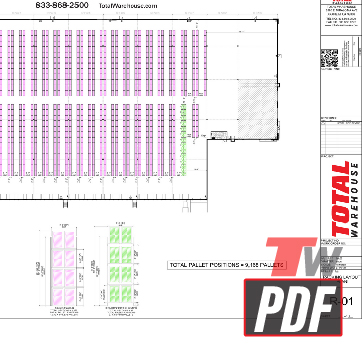

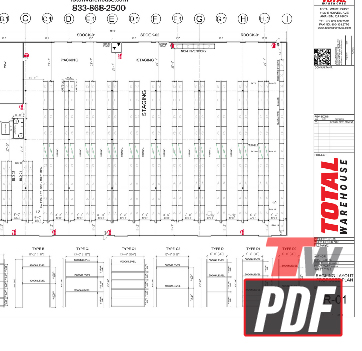

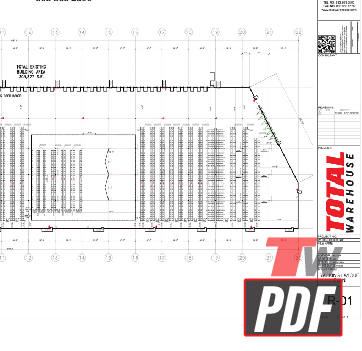

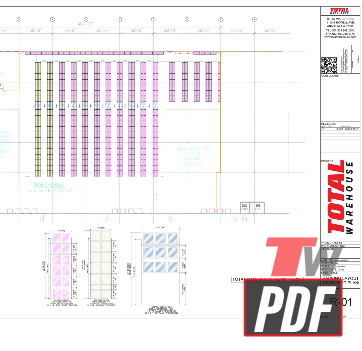

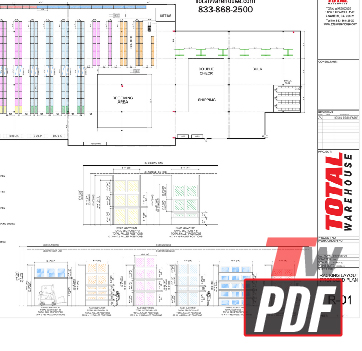

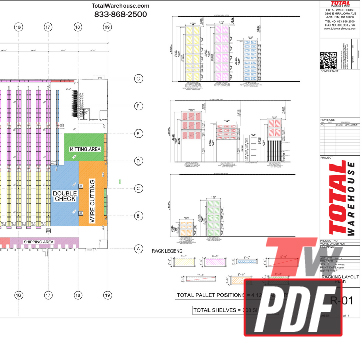

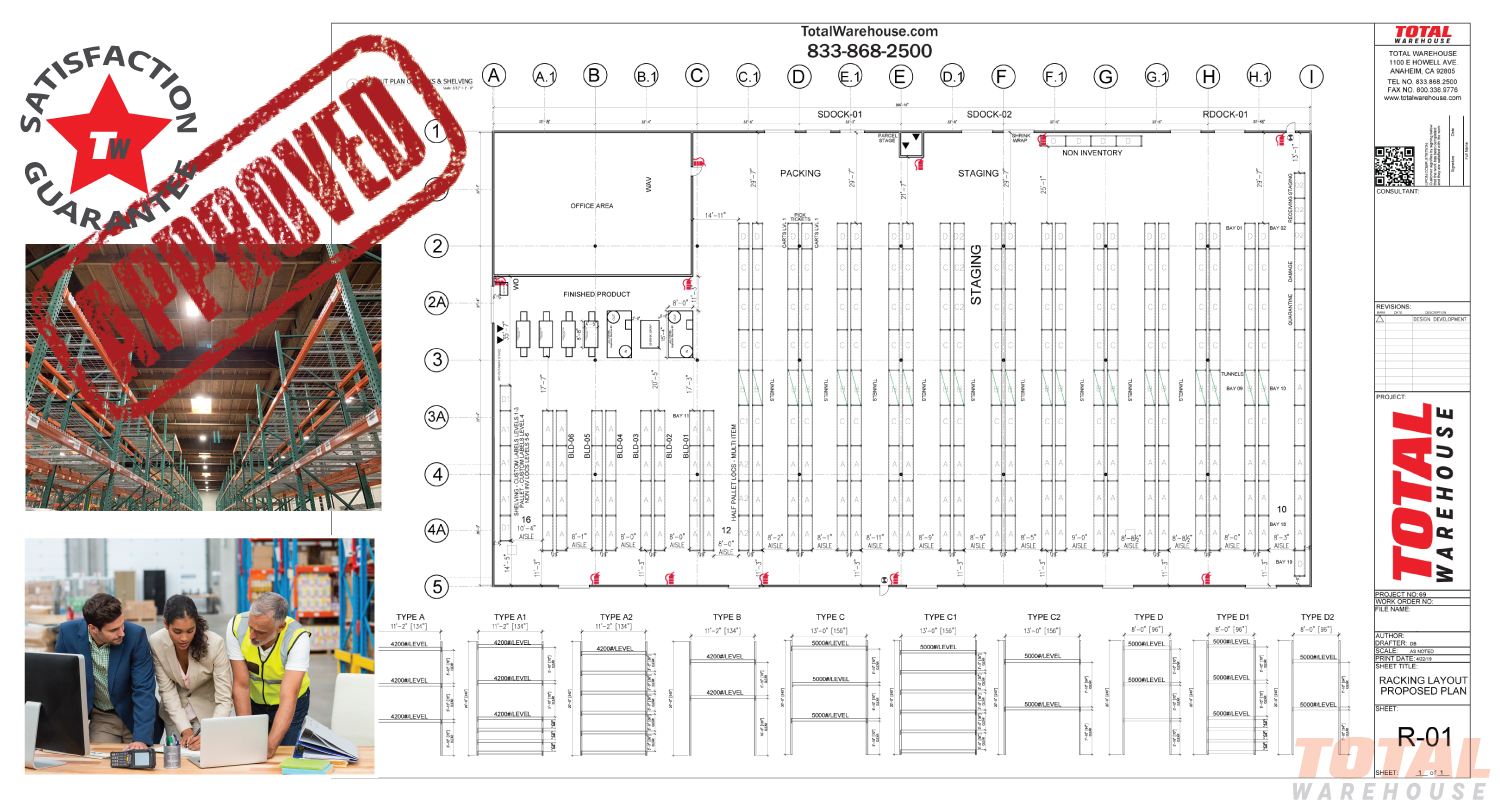

Our system design and engineering team utilizes cutting-edge CAD software to tailor your storage racking systems. Your personalized design encompasses various elements: existing structures, planned office spaces, material handling systems, pedestrian zones, vehicle aisles, fire safety measures, and emergency exits.

Total Warehouse Engineering & Design

- Pallet racking systems

- Pick modules

- Dynamic Storage Racks

- Conveyors

- Industrial Shelving

- Automated systems and equipment integration

We determine storage rack designs that align with your inventory throughput objectives and product specifications, emphasizing streamlined processes and minimal handling.

Pallet Racking Solutions for Businesses

Tailor your warehouse storage and processing solutions to align with your specific operational requirements considering factors such as budget, labor availability, and equipment capabilities.

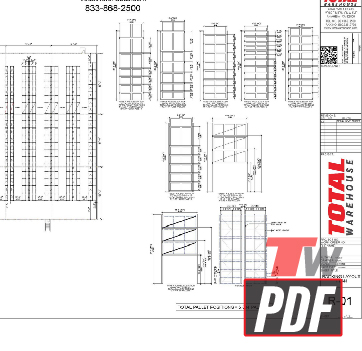

Engineering & Design Deliverables:

- Concept and Installation Drawings

- Building: Floor Plan, Warehouse Storage, Pallet Racking Elevations

- Detailed CAD Drawings

- Equipment Load Capacities

- Seismic Design

- Inventory Slotting Analysis

- High-Pile Analysis

With extensive industry experience spanning sectors like food & beverage, retail, manufacturing, automotive, 3PL, electronics, home & garden supply, and more, we’re equipped to meet your unique needs.

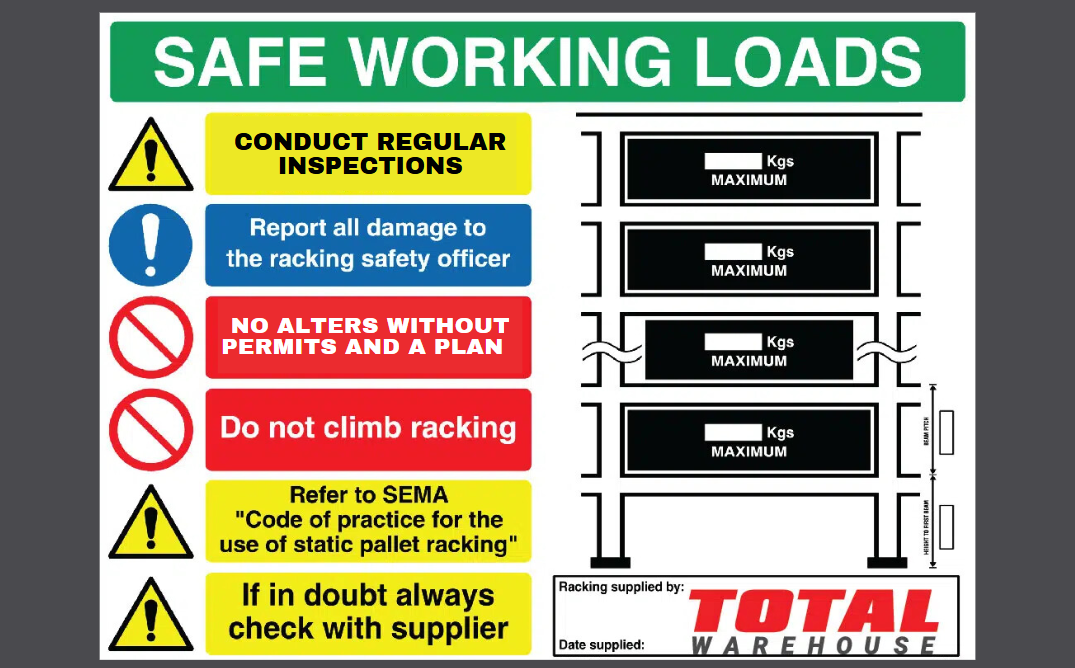

Navigate Permits and Safety Standards for Your Rack System

Before building any rack system, it is critical to triple check the permitting requirements and warehouse safety standards in your state and local jurisdiction.

We are committed to managing the demanding process of acquiring permits for warehouse rack projects. This relieves you from the stress of ensuring compliance, handling paperwork, coordinating with multiple parties, and enduring long waits at the permit office.

- We handle the Permit Submittal & Acquisition

- Ensure Compliance with Regulations & Codes

- Receive Proper Warehouse Rack Permitting

Why Seismic Zones Matters in Warehouse Rack

Seismic zones are crucial for warehouse racking as they determine the level of earthquake resistance required to ensure safety and compliance. Properly designed racking systems in high-risk seismic areas prevent collapses, protecting inventory, employees, and operations. Adhering to seismic standards reduces damage, minimizes downtime, and enhances overall warehouse stability.

Partner with Total Warehouse Engineers for seismic-compliant racking.

Enhance Safety In Your Building

Pallet packing systems are a smart way to enhance safety in your building. By installing clear, properly-sized aisles and pallet shelves, you ensure forklifts can maneuver safely while storing products to code, reducing the risk of accidents. Additionally, these systems help maximize warehouse storage and minimize operational expenses, creating a more efficient and cost-effective operation!

View Our Catalog: Catalog Page

Check out our article on guidelines for maintaining warehouse space. Learn new strategies for optimizing space utilization in your warehouse.

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

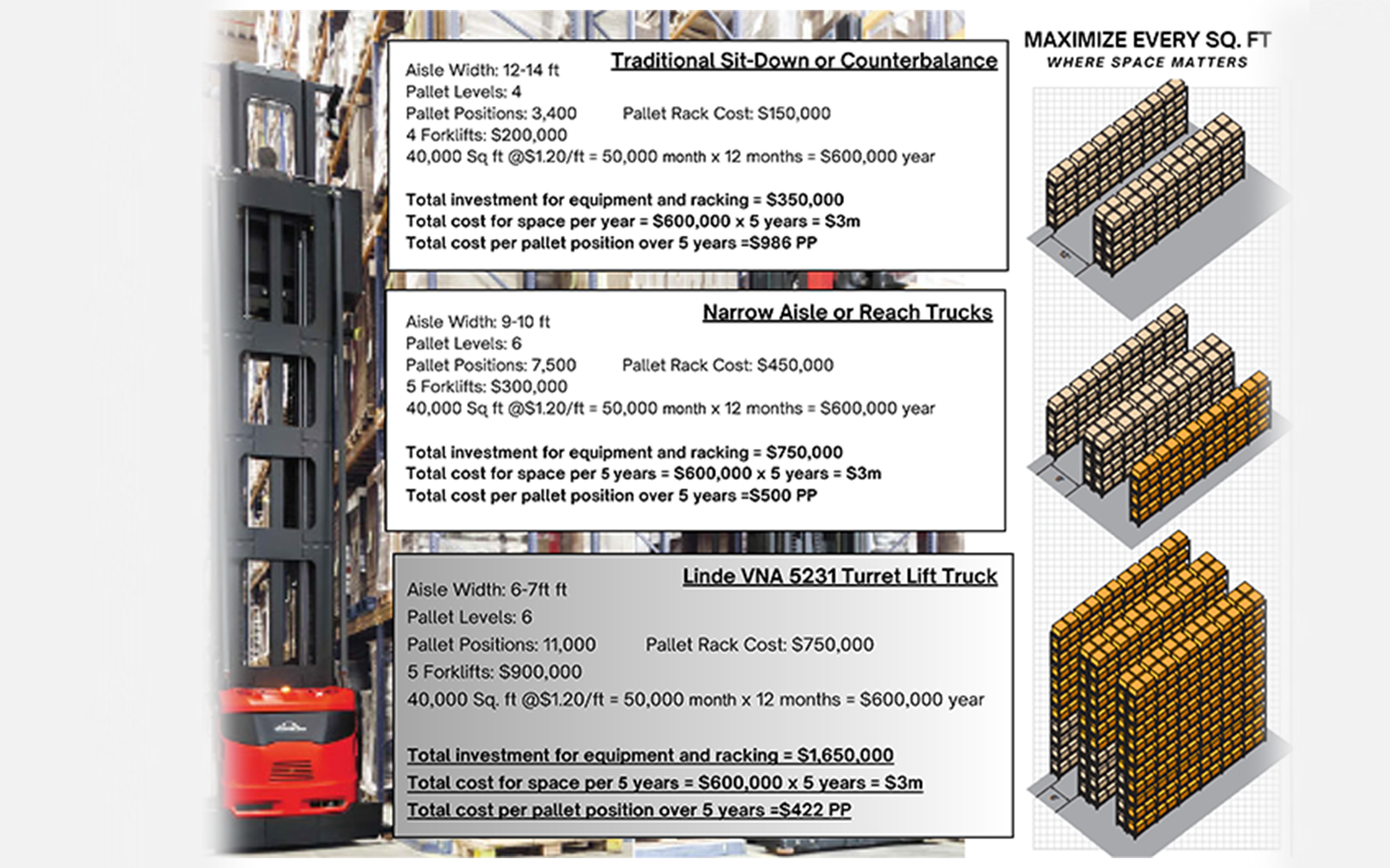

Capacity & Throughput

Achieve More in Less Time

With our expert engineering and racking solutions, you can amplify your storage capacity utilization. Increasing your pallet positions will bring huge value to your bottom line.

- Maximize Your Square Foot

- Maximize Your Equipment Investment

- Maximize Your Racking Investment

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.