Key Features

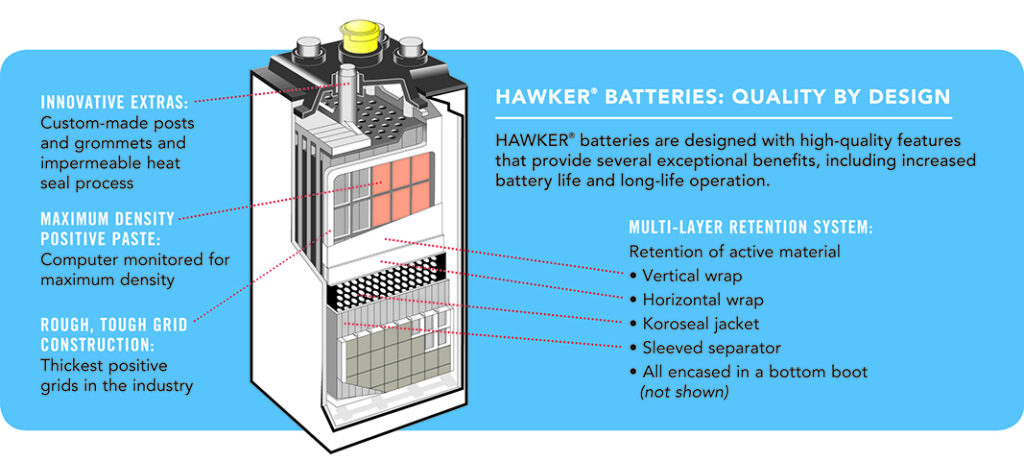

Maximize equipment performance with HAWKER® POWERLINE® flooded lead-acid batteries, ideal for various forklift types. The design and construction of POWERLINE® batteries ensure superior performance and extended lifespan.

Our rugged positive grid construction, featuring the thickest grid in the industry, ensures improved current distribution and extended battery life with reduced corrosion and cooler operating temperatures.

The pasted plate is the heart and soul of your lead-acid battery. The positive grids are pasted with the most active material and is the densest available anywhere in the industry today. Dense positive paste ensures long-life operation under deep cycling as well as continued, uninterrupted power.

Sleeved separators are made of the highest-quality, microporous plastic material available. Sleeved separators eliminate failures caused by separator misalignment.

Our revolutionary formation system uses an acid recirculation and two shot forming processes. This ensures that every cell of every battery receives a uniform temperature-controlled acid bath.

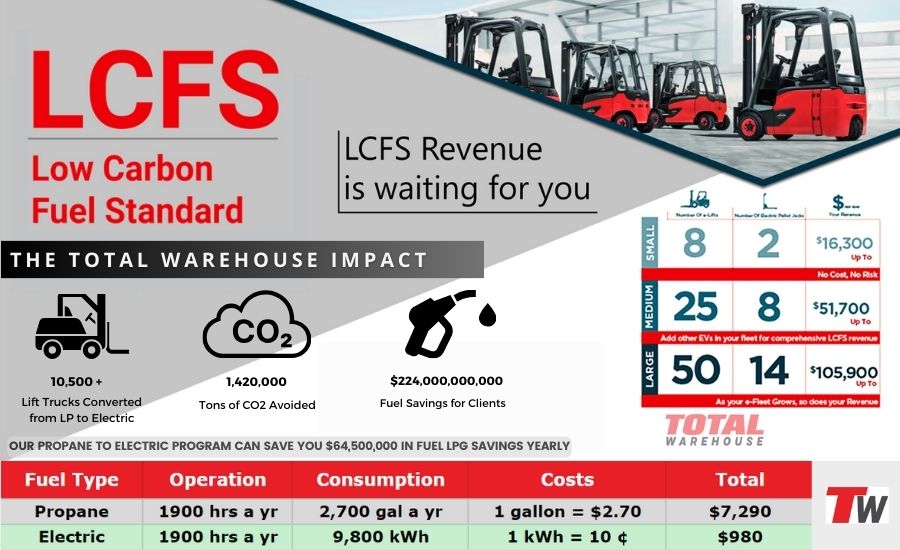

Zero Emission Forklift Mandate

With the Zero Emission Forklifts Regulation, CARB plans to ban sales of all new forklifts that are not zero-emission by 2026 to improve air quality and reduce pollution.

- Starting in 2026, businesses cannot purchase or lease new internal combustion (IC) engine forklifts

- Mandates the replacement of propane forklifts with zero-emission engines such as electric

Learn More: Zero-Emission Forklift Regulation – Fleet Impact?

How Can Total Warehouse Help?

Expert Consultation: We provide the right electric forklifts and ensure compliance with CARB regulations.

Zero-Emission Options: Our electric forklifts meet zero-emission standards and fit your fleet needs.

Incentives: We guide you through state incentives, tax credits, and rebates.

Transition Support: We support in phasing out old forklifts for electric models and upgrading infrastructure.

Learn More: Total Warehouse’s Electric Energy Solutions

Cost of Ownership

Propane vs Lead Acid vs TPPL vs LithiumHow to Use This Calculator

- Enter your fleet size and annual operating days at the top

- Adjust the values for each energy type (hover over inputs for details)

- The calculator will automatically update results 3 seconds after your last change

- Compare the yearly costs and potential savings across different energy types

- Results are color-coded (green for savings, red for costs)

This calculator helps you compare the cost of ownership between Propane, Lead Acid, TPPL, and Lithium power sources for your fleet.

General Parameters

Propane

Lead Acid (810)

TPPL (770)

Lithium (518)

Costs Calculation Results

| Model | Propane | Lead Acid | TPPL | Lithium |

|---|---|---|---|---|

| Annual Cost by Life Expectancy | $0.00 | $0.00 | $0.00 | $0.00 |

| Annual Fuel/Elec Cost Per Truck | $0.00 | $0.00 | $0.00 | $0.00 |

| Annual Fleet Cost | $0.00 | $0.00 | $0.00 | $0.00 |

| Total Fleet Savings 1Yr | $0.00 | $0.00 | $0.00 | $0.00 |

| Total Fleet Savings 5Yr | $0.00 | $0.00 | $0.00 | $0.00 |

| Total Fleet Savings 10Yr | $0.00 | $0.00 | $0.00 | $0.00 |

Quality by Design

Our POWERLINE™ batteries provide superior performance and long life cycle that is based on the battery’s design and construction.

Hawker Chargers

Complete Energy Solution

Explore our smartest and most energy-efficient charger line in the business. We offer different charge profile options for operational flexibility, we ensure peak efficiency and non-stop power while reducing your battery charging costs, water consumption, and battery maintenance and repair costs.

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.