Key Features

Narrow aisle storage offers high storage density but places demands on drivers due to numerous storage locations, often resulting in misplaced pallets.

Linde Warehouse Navigation addresses this challenge by guiding drivers efficiently, enhancing productivity in narrow aisle warehouses.

Avoid errors and maximize productivity in the warehouse by identifying the sources of errors in advance and show the drivers the most efficient path between the 2 points in the high rack every time.

Learn More About Linde Warehouse Navigation

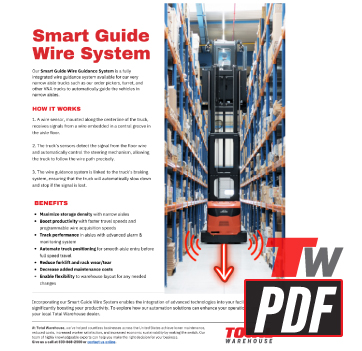

Linde Smart Guide Wire Guidance System is a fully integrated wire guidance system available for our VNA trucks to automatically guide the vehicles in narrow aisles.

A wire sensor mounted on the center of the truck receives signals from a wire buried in a groove in the stacking aisle floor. This signal controls the steering, allowing the truck to automatically follow the wire system.

Operators are freed from manual steering tasks and can focus on maximizing their productivity in tasks like order picking.

Learn More About Linde Smart Guide Wire Guidance System

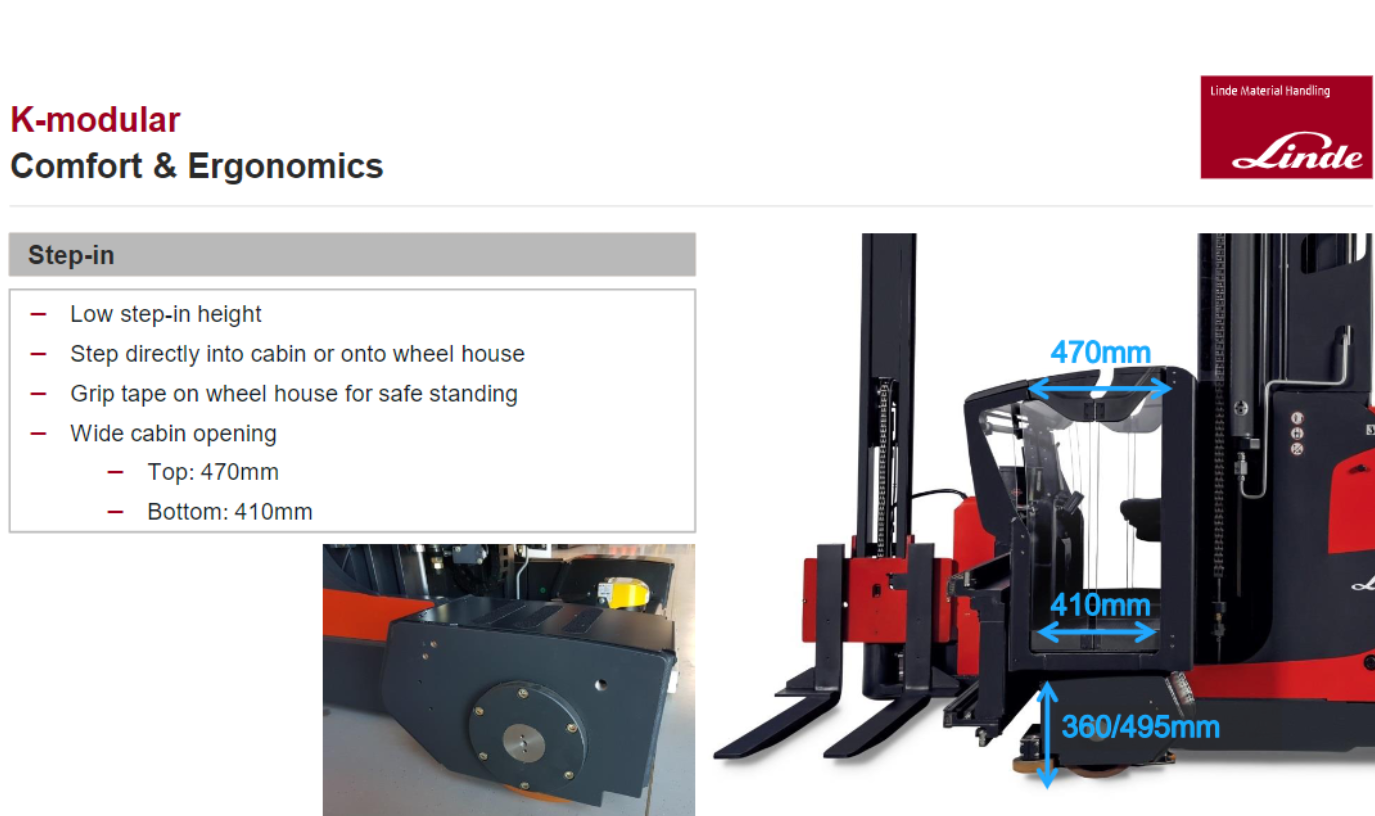

Experience the comfort and ergonomics from the Linde 5231 Turret Truck

- Low Step on Height for Easy On and Off

- Step Directly into Cabin or onto Wheel House

- Grip Tape on Wheel House for Safe Standing

- Wide Cabin Opening

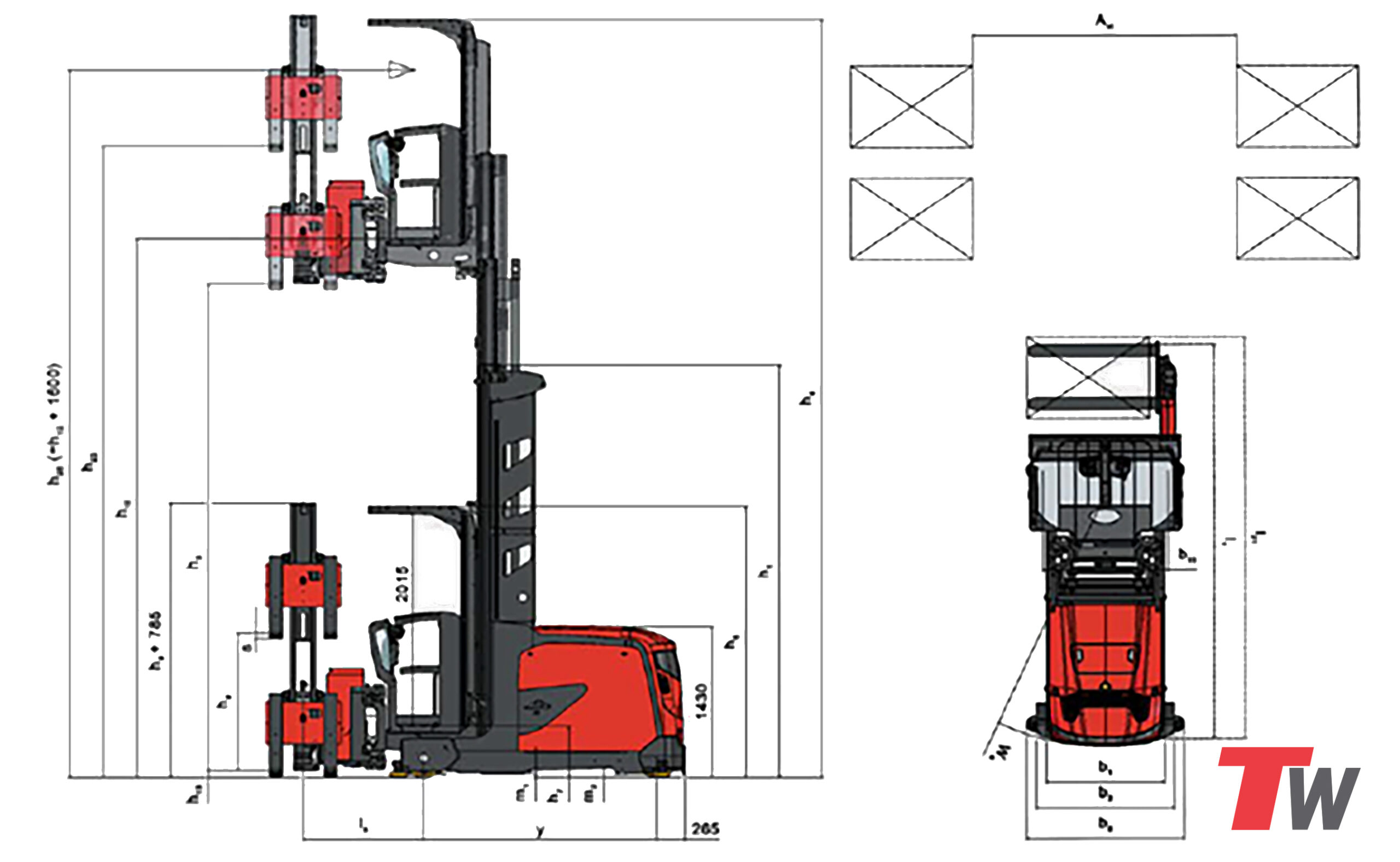

Unique modular design concept enables perfect individualization for each application.

- Truck capacities ranging from 2,500 to 3,500 lbs

- Optimized cabins for picking, storage, or combined use

- Flexible chassis widths for diverse needs

The K truck’s excellent cabin design provides operators with immediate comfort and familiarity. With ample space for movement, the cab ensures a comfortable working environment, reducing fatigue and enhancing efficiency and productivity.

The Operators Cabin is extremely robust, and opens easily for convenient entry and exit, along with comfortable cushioning supports for operator when leaning over the barriers.

- Reduced shock and vibration due to isolation of cabin from chassis.

- Easy and low access height.

- Various comfortable and adjustable seats.

- 3 different Cabins available– Combi cabin (combined picking/ stacking) – Comfort cabin with +100mm more depth – Cold store cabin (-30°C)

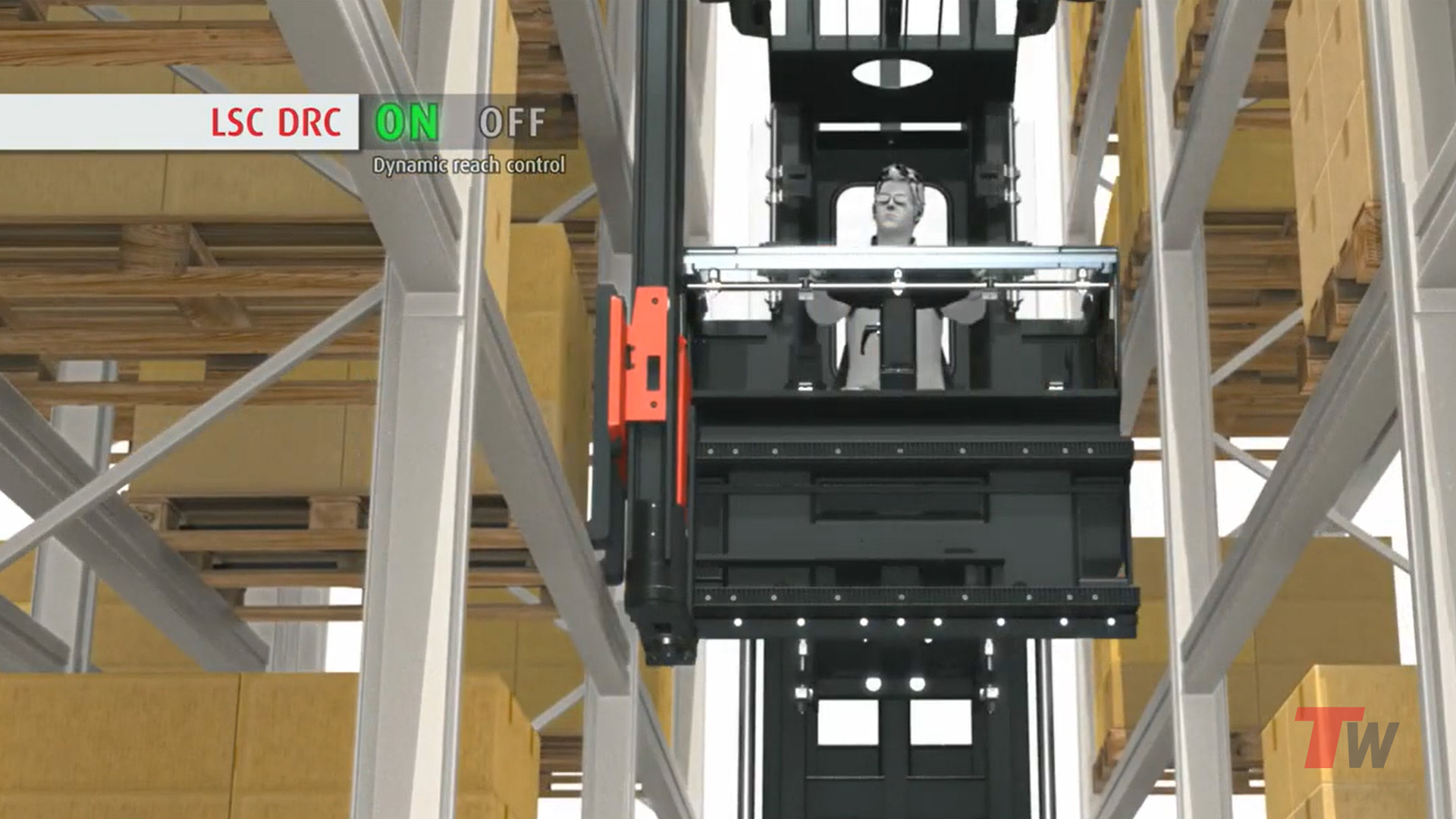

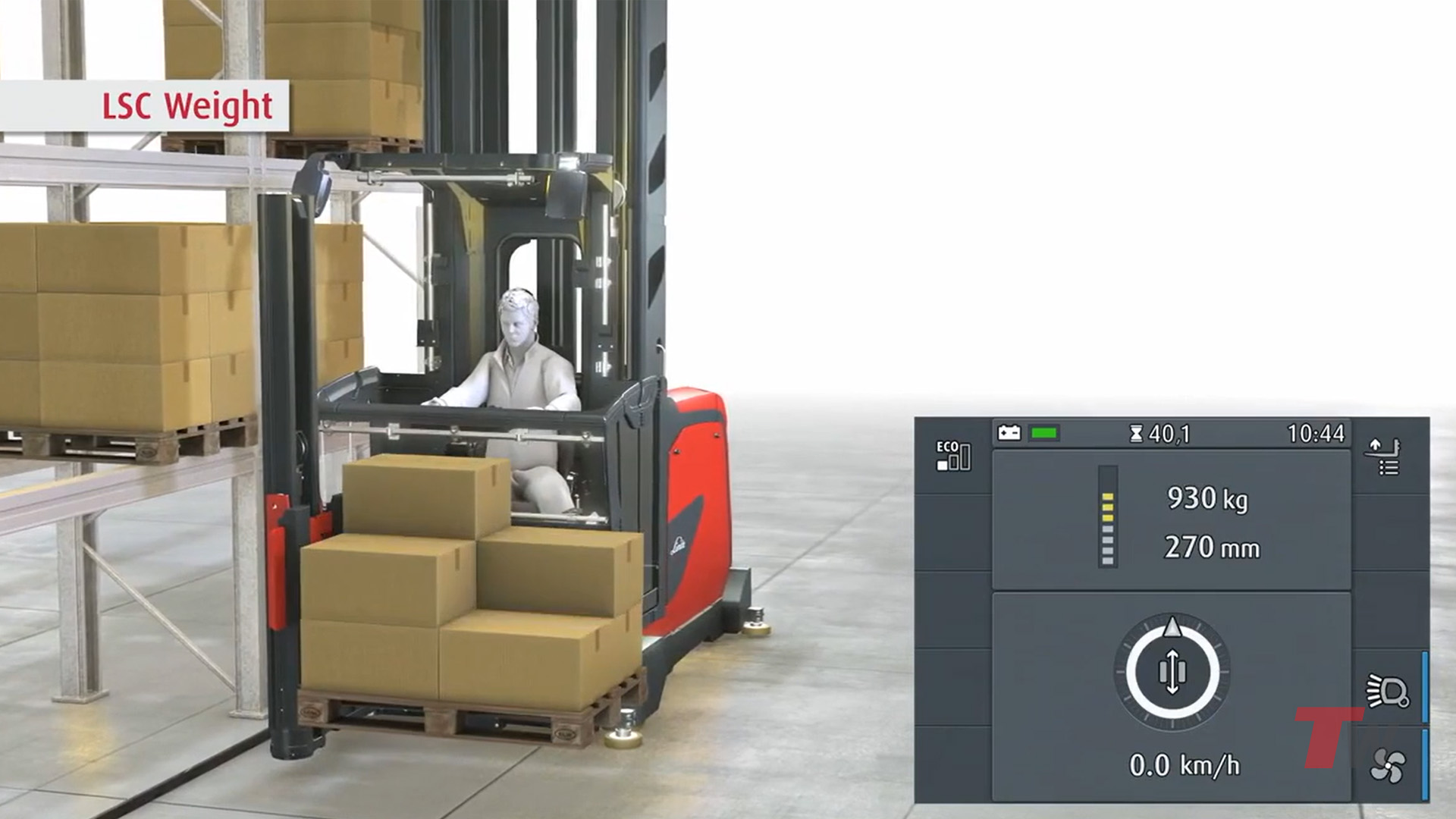

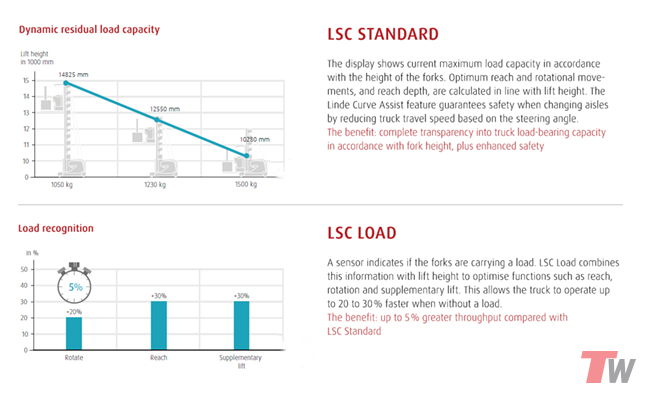

The Linde System Control (LSC) is powerful, pioneering technology to ensure optimum control of its VNA man-up and man-down trucks.

LSC employs a sensor to detect the height of the fork, and calculates the maximum residual load capacity. The speed of the truck is automatically adjusted in accordance with the detected height. This all occurs in real time and is displayed to the operator.

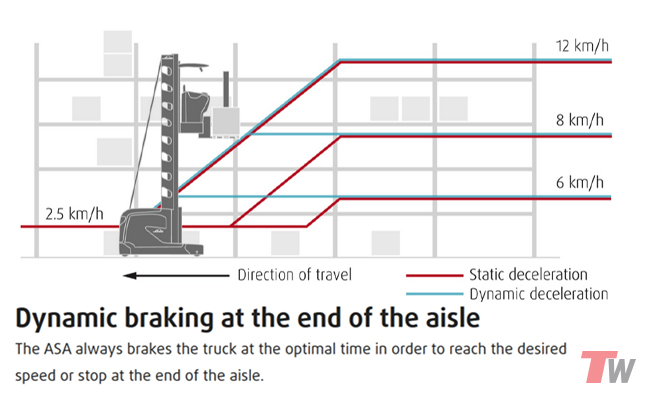

With Linde Material Handling’s Aisle Safety Assistant (ASA), narrow aisle trucks adapt their movements to warehouse conditions, minimizing collision risks and potential damage to goods and infrastructure.

Functioning akin to driver assistance systems in cars, ASA enables narrow aisle trucks to navigate using RFID tags or barcodes, maintaining precise positioning and height awareness throughout the warehouse.

By digitally marking obstacles and integrating truck dimensions, ASA prevents collisions by automatically halting narrow aisle trucks when nearing marked areas, ensuring safe navigation within the warehouse environment.

Integrated diagnostic CAN bus technology minimizes maintenance intervals.

- Easy access to all service relevant components enables quick maintenance and low downtimes.

- The new oil tank is designed for quick access and short maintenance, as well as for optimized foaming behavior.

Q: What is a turret truck (VNA truck)? A: A turret truck, also known as a very narrow aisle (VNA) truck or swing-reach truck, is a forklift designed for extremely narrow aisles in warehouses, maximizing storage density.

Q: How does a turret truck differ from a standard forklift? A: Unlike standard counterbalance forklifts, turret trucks operate in much narrower aisles (narrow aisle forklifts) due to their rotating forks.

Q: What is a man-up turret truck? A: A man-up turret truck lifts the operator with the load, providing better visibility for high-level order picking.

Q: What is a man-down turret truck? A: A man-down turret truck keeps the operator at ground level, suitable for certain warehouse applications.

Q: What are the advantages of using turret trucks? A: Turret trucks increase storage capacity, improve space utilization, and enhance warehouse efficiency in high-density storage.

Q: What is the minimum aisle width for a turret truck? A: Turret trucks can operate in aisles as narrow as 5.5 to 6 feet, significantly reducing aisle width compared to standard forklifts.

Q: What is the lifting capacity of a turret truck? A: Lifting capacity varies depending on the model, but they are designed for heavy-duty material handling in narrow aisles.

Q: How do turret truck forks rotate? A: Turret truck forks rotate 90 or 180 degrees, allowing them to pick and place loads without turning the entire truck.

Q: What is the typical mast height of a turret truck? A: Mast height varies, enabling access to high-level racking systems in warehouses.

Q: What type of training is required to operate a turret truck? A: Specialized turret truck operation training is essential due to the truck’s unique features and narrow aisle operation.

Q: What are the key safety considerations for turret truck operation? A: Safety considerations include aisle clearance, floor conditions, load stability, and proper fall protection in man-up trucks.

Q: What are common causes of turret truck accidents? A: Common causes include collisions with racking, tipping due to uneven loads, and falls from man-up platforms.

Q: How is a turret truck powered? A: Most turret trucks are electric, powered by batteries, promoting environmentally friendly warehouse operations.

Q: What is the battery life of a turret truck? A: Battery life depends on usage and maintenance, but proper battery management is crucial for continuous operation.

Q: How is a turret truck battery charged? A: Turret truck batteries are charged using industrial battery chargers designed for high-capacity batteries.

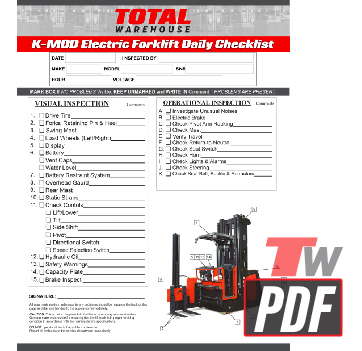

Q: What is the maintenance schedule for a turret truck? A: Regular preventative maintenance, including daily checks and periodic servicing, is essential for optimal performance.

Q: Where can I find turret truck parts? A: Turret truck parts can be sourced from material handling equipment suppliers and specialized forklift parts dealers.

Q: How much does a new turret truck cost? A: The price of a turret truck varies based on specifications and features, generally costing more than standard forklifts.

Q: Where can I rent a turret truck? A: Turret trucks are available for rent from material handling equipment rental companies.

Q: What are the advantages of renting a turret truck? A: Renting offers flexibility and avoids the upfront cost of purchasing, suitable for short-term needs.

Q: What is the difference between a turret truck and a reach truck? A: Reach trucks extend forks forward, while turret trucks rotate forks, allowing for narrower aisle operation.

Q: What is the role of a turret truck in warehouse optimization? A: Turret trucks play a key role in optimizing warehouse space and improving storage density.

Q: How do turret trucks improve logistics efficiency? A: By maximizing storage capacity, turret trucks streamline material flow and enhance logistics operations.

Q: What is the impact of turret trucks on supply chain management? A: Efficient warehouse operations with turret trucks contribute to a more effective supply chain.

Q: Are there automated turret trucks? A: Yes, automated guided vehicles (AGVs) are increasingly used in conjunction with or as replacements for traditional turret trucks.

Q: What are the benefits of automated turret trucks (AGVs)? A: AGVs improve efficiency, reduce labor costs, and enhance safety through automated material handling.

Q: How do turret trucks interact with warehouse racking systems? A: Turret trucks are designed to operate within specific narrow aisle racking systems for optimal storage.

Q: What are the different types of warehouse racking used with turret trucks? A: Common racking types include selective pallet racking and double-deep racking configured for narrow aisle operation.

Q: How does a turret truck handle different types of loads? A: Turret trucks can handle various pallet sizes and load types with appropriate fork adjustments and attachments.

Q: What are some common turret truck attachments? A: Attachments include specialized forks, clamps, and other devices for handling specific materials.

Q: What is the importance of floor conditions for turret truck operation? A: Smooth and level floors are crucial for stability and safe operation of turret trucks.

Q: How do uneven floors affect turret truck stability? A: Uneven floors can cause tipping and instability, posing safety risks during operation.

Q: What are the OSHA regulations related to turret truck operation? A: OSHA sets safety standards for forklift operation, including specific requirements for narrow aisle trucks.

Q: How do I get certified to operate a turret truck? A: Certified training programs are available through various organizations and material handling equipment dealers.

Q: What is the lifespan of a turret truck? A: With proper maintenance, turret trucks can have a long lifespan, providing years of reliable service.

Q: What are the long-term cost benefits of using turret trucks? A: While the initial investment is higher, long-term benefits include increased storage capacity and improved efficiency.

Q: How do turret trucks contribute to sustainable warehousing practices? A: Electric-powered turret trucks reduce emissions and promote environmentally friendly operations.

Q: What is the resale value of a used turret truck? A: Resale value depends on the age, condition, and model of the truck, but well-maintained units retain value.

Q: How do I choose the right turret truck for my warehouse? A: Factors to consider include aisle width, lifting capacity, mast height, and specific application requirements.

Q: What are the latest advancements in turret truck technology? A: Advancements include improved battery technology, automation features, and enhanced safety systems.

Q: What is the role of technology in modern turret truck operation? A: Technology plays a crucial role in improving efficiency, safety, and data tracking in modern turret trucks.

Q: How are turret trucks used in cold storage warehouses? A: Specialized turret trucks are designed for operation in cold storage environments with temperature-controlled features.

Q: What are the challenges of operating turret trucks in cold storage? A: Challenges include battery performance in low temperatures and operator comfort.

Q: How do turret trucks improve order picking efficiency? A: Man-up turret trucks provide excellent visibility for efficient order picking at high elevations.

Q: What are the different types of turret truck control systems? A: Control systems vary, including traditional levers and more advanced joystick controls.

Q: How does the weight of the load affect turret truck stability? A: Overloading can cause instability and tipping, emphasizing the importance of adhering to capacity limits.

Q: What are the different types of tires used on turret trucks? A: Tire types vary depending on the floor surface and operating environment.

Q: How do I inspect a turret truck before operation? A: Pre-operation inspections should include checks of tires, forks, mast, controls, and safety features.

Q: What should I do if a turret truck malfunctions during operation? A: Operators should follow established safety procedures and report any malfunctions immediately.

Q: How can I improve turret truck operator productivity? A: Proper training, efficient warehouse layout, and effective communication can enhance operator productivity.

Q: What is the relationship between turret trucks and warehouse design? A: Warehouse design should consider the specific requirements of turret truck operation, including aisle width and racking layout.

Q: How do turret trucks impact warehouse throughput? A: By maximizing storage capacity and improving efficiency, turret trucks enhance warehouse throughput.

Q: What is the difference between a swing mast truck and a turret truck? A: While similar, swing mast trucks typically swing the entire mast assembly, while turret trucks rotate the forks.

Q: What are the advantages of using a swing mast truck? A: Swing mast trucks can offer flexibility in certain applications, but turret trucks generally excel in very narrow aisles.

Q: How do turret trucks contribute to reducing product damage? A: Precise handling and controlled movements minimize the risk of damage to goods during storage and retrieval.

Q: What is the importance of proper load distribution on a turret truck? A: Even load distribution is essential for maintaining stability and preventing tipping.

Q: How do turret trucks operate in congested warehouse environments? A: Their narrow aisle capabilities allow them to operate efficiently even in congested spaces.

Q: What are the challenges of operating turret trucks in older warehouses? A: Older warehouses may have limitations in floor conditions or ceiling height that can affect turret truck operation.

Q: How do turret trucks contribute to improved inventory management? A: By maximizing storage capacity and optimizing storage locations, turret trucks facilitate better inventory control.

Q: What are the different types of turret truck guidance systems? A: Guidance systems include wire guidance, rail guidance, and laser guidance, ensuring precise movement in narrow aisles.

Q: How does wire guidance work in turret trucks? A: Wire guidance uses an embedded wire in the floor to guide the truck along a predetermined path.

Q: How does rail guidance work in turret trucks? A: Rail guidance uses rails embedded in the floor to provide precise tracking for the truck.

Q: How does laser guidance work in turret trucks? A: Laser guidance uses lasers and reflectors to guide the truck along a defined path.

Q: What are the advantages of using guidance systems in turret trucks? A: Guidance systems improve accuracy, reduce operator fatigue, and enhance safety in narrow aisle operations.

Q: How do I select the right guidance system for my turret truck? A: The choice of guidance system depends on factors such as warehouse layout, floor conditions, and operational requirements.

Q: What is the impact of turret trucks on labor costs? A: By maximizing storage capacity and improving efficiency, turret trucks can reduce the need for additional warehouse space and labor.

Q: How do turret trucks contribute to a safer work environment? A: By reducing the need for manual handling and minimizing congestion, turret trucks enhance workplace safety.

Q: What are the ergonomic considerations for turret truck operators? A: Ergonomic design features, such as adjustable seats and intuitive controls, help reduce operator fatigue and improve comfort.

Q: How do turret trucks interact with warehouse management systems (WMS)? A: Integration with WMS allows for optimized storage locations, efficient order picking, and real-time inventory tracking.

Q: What are the benefits of integrating turret trucks with WMS? A: Integration improves efficiency, accuracy, and visibility throughout the warehouse operation.

Q: How do turret trucks contribute to improved customer service? A: By optimizing warehouse operations and ensuring timely order fulfillment, turret trucks support enhanced customer service.

Q: What are the future trends in turret truck technology? A: Future trends include increased automation, improved battery technology, and enhanced safety features.

Q: How do turret trucks compare to other types of narrow aisle equipment? A: Turret trucks offer unique advantages in very narrow aisles compared to other equipment like reach trucks or order pickers.

Q: What are the limitations of using turret trucks? A: Turret trucks require specialized training, specific aisle configurations, and smooth floor conditions.

Q: How do I assess the suitability of turret trucks for my warehouse operations? A: A thorough analysis of storage needs, aisle widths, and operational requirements is essential.

Q: What are the key performance indicators (KPIs) for turret truck operation? A: KPIs include throughput, utilization, and safety metrics.

Q: How do I measure the effectiveness of turret truck operations? A: Tracking KPIs and analyzing operational data can help measure effectiveness.

Q: What are the best practices for managing a fleet of turret trucks? A: Best practices include regular maintenance, operator training, and efficient scheduling.

Q: How can I optimize the layout of my warehouse for turret truck operation? A: Careful planning of aisle widths, racking configurations, and traffic flow is crucial.

Q: What are the different types of turret truck forks available? A: Different fork lengths, widths, and profiles are available to accommodate various load types.

Q: How do I choose the right forks for my turret truck? A: The choice of forks depends on the type of loads being handled and the racking system used.

Q: What are the different types of turret truck masts available? A: Different mast configurations offer varying lift heights and reach capabilities.

Q: How do I choose the right mast for my turret truck? A: The choice of mast depends on the required lift height and the height of the racking system.

Q: What are the different types of turret truck tires available? A: Tire types include solid tires, pneumatic tires, and polyurethane tires, each suited for different floor conditions.

Q: How do I choose the right tires for my turret truck? A: The choice of tires depends on the floor surface, operating environment, and load weight.

Q: What are the environmental considerations for turret truck operation? A: Electric-powered turret trucks contribute to reducing emissions and promoting sustainable operations.

Q: How can I reduce the environmental impact of turret truck operations? A: Efficient battery management, proper maintenance, and optimized routing can minimize environmental impact.

Q: What are the social considerations for turret truck operation? A: Ensuring operator safety, providing proper training, and promoting a positive work environment are important social considerations.

Q: How can I improve the social impact of turret truck operations? A: Investing in operator training, promoting safety awareness, and fostering a positive work culture can enhance social impact.

Q: What are the economic considerations for turret truck operation? A: Evaluating the costs and benefits of using turret trucks is essential for making informed investment decisions.

Q: How can I maximize the economic benefits of turret truck operations? A: Optimizing storage capacity, improving efficiency, and reducing operating costs can maximize economic returns.

Q: What are the legal requirements for operating turret trucks? A: Operators must be properly trained and certified according to relevant safety standards and regulations.

Q: How can I ensure compliance with legal requirements for turret truck operation? A: Implementing proper training programs, conducting regular inspections, and maintaining accurate records are essential.

Q: What are the ethical considerations for turret truck operation? A: Operating turret trucks safely and responsibly, respecting workplace safety rules, and promoting ethical business practices are important.

Q: How can I promote ethical conduct in turret truck operations? A: Establishing clear ethical guidelines, providing ethics training, and fostering a culture of accountability can promote ethical behavior.

Q: What is the role of leadership in promoting safe and efficient turret truck operations? A: Strong leadership is essential for setting safety standards, providing resources, and fostering a culture of safety and efficiency.

Q: How can I improve communication regarding turret truck operations? A: Clear communication protocols, regular safety meetings, and effective feedback mechanisms can enhance communication.

Q: What is the importance of continuous improvement in turret truck operations? A: Continuously seeking ways to improve safety, efficiency, and productivity is essential for long-term success.

Q: How can I foster a culture of continuous improvement in turret truck operations? A: Encouraging employee feedback, implementing process improvements, and tracking key performance indicators can promote continuous improvement.

Competitive Rates for Turret Trucks

Available for Rent, Lease, and Sale

Total Warehouse has a massive rental fleet ready to be delivered to your business at a moment’s notice. We offer daily, weekly, and monthly rental rates that allow you to maximize operations at the bare minimum cost. We have you covered with the top material handling products for operational optimization that is customized to your specific needs.

| Model | Capacity (lbs) | Lift (ft) | Battery voltage / rated capacity |

| KTURRET_5231_0.7 | 1400 | 18' | 48 V |

| KTURRET_5231_0.9 | 1800 | 23' | 80 V |

| KTURRET_5231_1.5 | 3000 | 51' | 80 V |

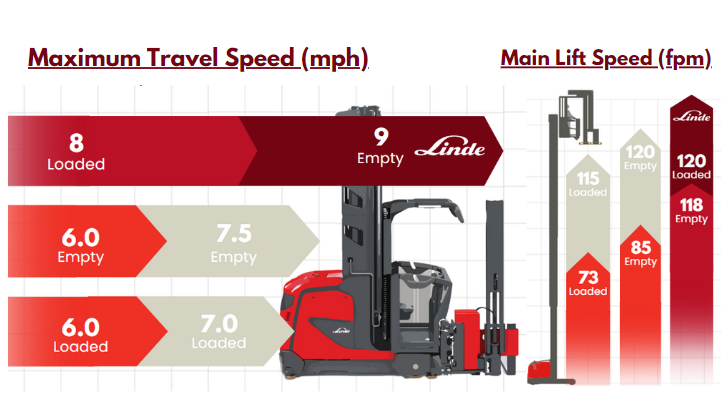

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

Strong motors enable high lift- and driving-speeds, while the ergonomic control panel enables quick load handling with minimal hand movement. Assisting systems like LSC or the Aisle Safety Assist support the operator for maximum throughput in safe operation. The innovative Active Stability Control assistance system ensures a smooth and fast travel speed even on floors that do not comply with VDMA guidelines. The electro-mechanical sensors identify and automatically compensate for unevenness of the floor to achieve maximum handling performance.

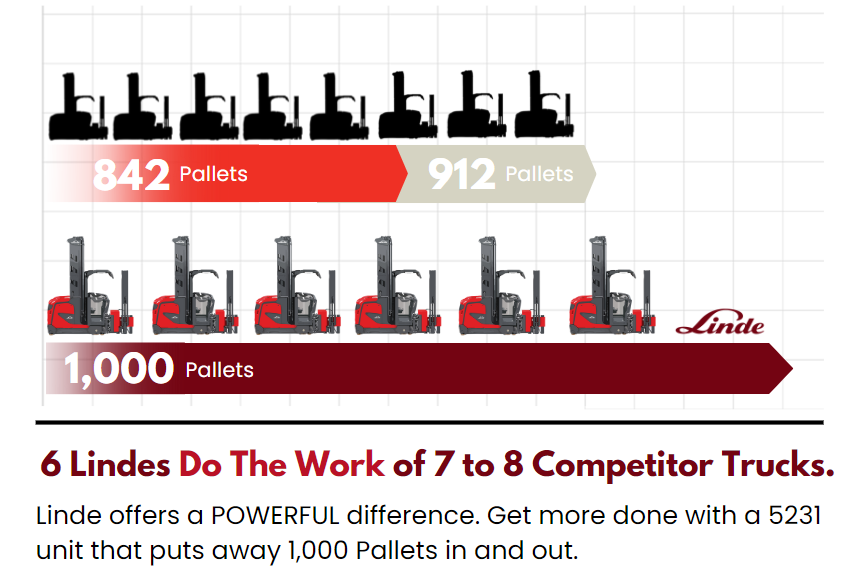

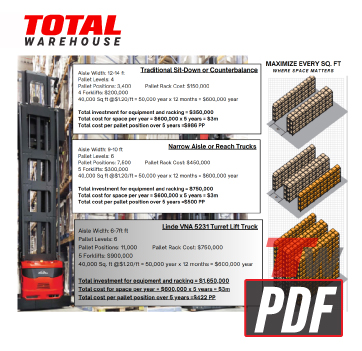

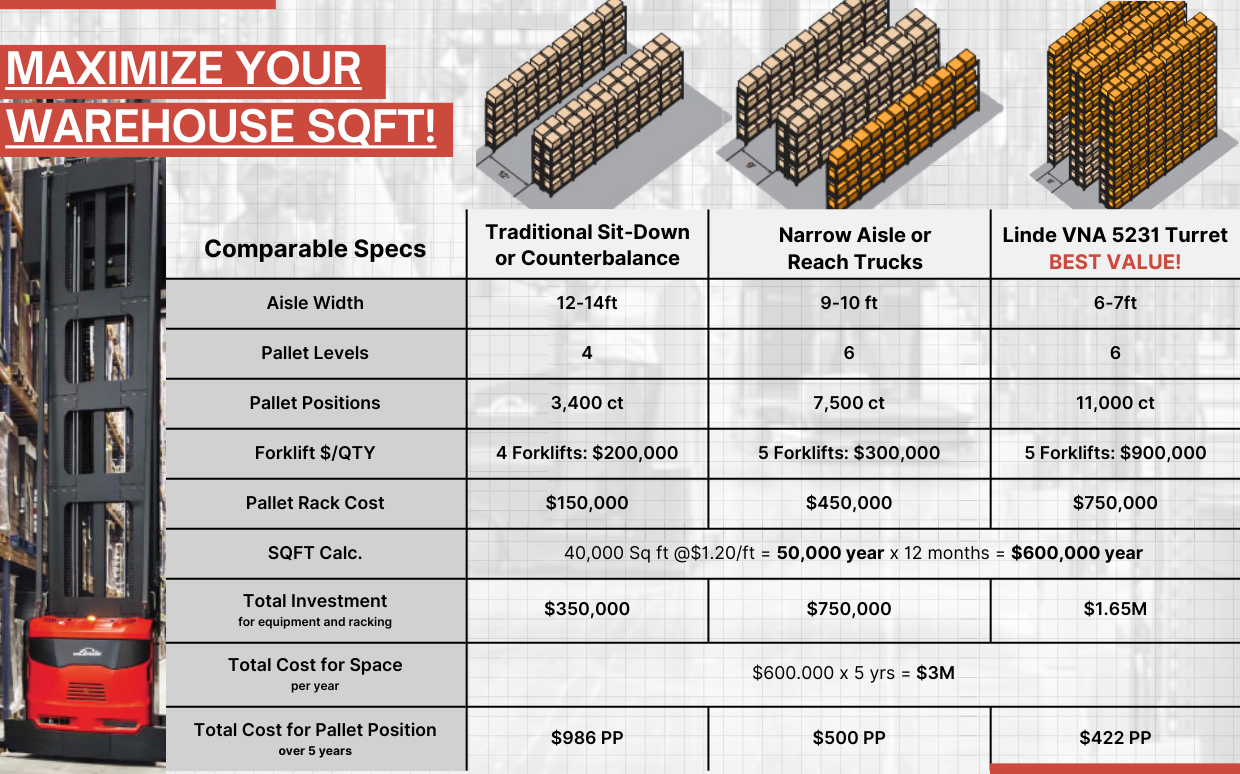

VNA Turret Truck

Make Every Square Foot Count

Amplify your storage capacity utilization with the LINDE VNA 5231 Turret Truck. Increasing your pallet positions will bring great value to your bottom line.

- Increase Pallet Levels

- Increase Pallet Positions

- Increase Capacity

- Get The Most Out Of Your Investment

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.