Key Features

The Electric Advantage

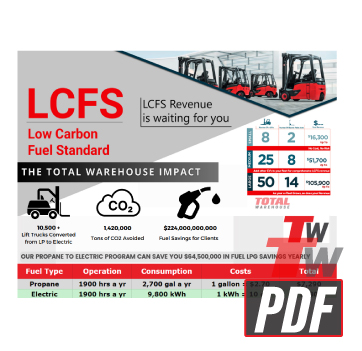

Electric forklifts, now 65% of the market, are replacing propane models with zero emissions and cost-saving benefits.

- Lower Cost of Ownership: Save on fuel, maintenance, and repairs despite higher upfront costs.

- Improve Operator Comfort: Quieter, smoother, and cooler operation to reduce operator fatigue.

- Zero Carbon Emissions: Cleaner environment with 100% emission reduction.

- Minimal Maintenance: Less parts and no oil changes = lower costs and more uptime.

Opportunity Charging

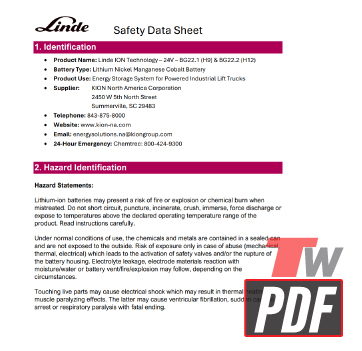

Lithium-ion battery technologies are ideal for multi-shift operations due to their ability to accept frequent opportunity charging at high rates throughout the shift without affecting the battery’s performance.

- Li-Ion increases uptime, allowing 1 battery to achieve more run time

- Outperforms lead acid batteries

- Save on replacements and service

Learn More: Opportunity Charging In Your Warehouse

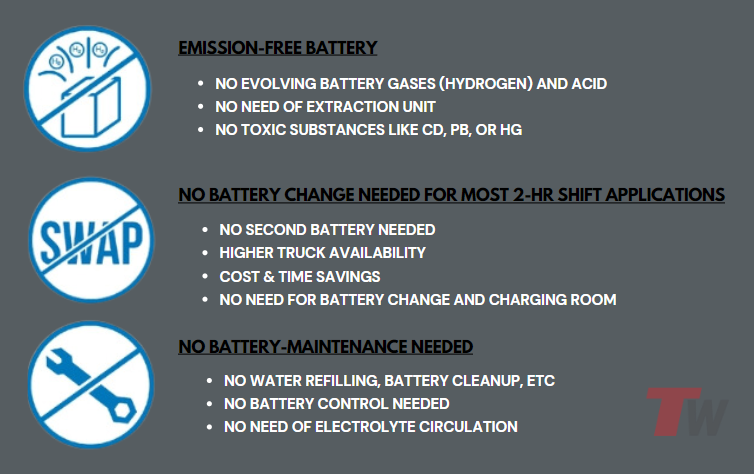

Innovative & Economical

Conventional lead-acid batteries comes with a whole series of maintenance and handling costs, which are completely eliminated with Li-ION batteries. These include the cost of a second battery, personnel costs for replenishing the batteries with water, and battery replacement.

- No need for battery swapping or downtime.

- More run time in a 24 hour period

- More cost efficient than lead acid, saving on replacements and service

- Performs better in low temperature environments

Learn More: Explore the Power of Lithium Ion Batteries and Chargers

Fast Recharging & High Energy Efficiency

Achieves a full charge cycle within 1 hour. Depending on the intensity of the operation, all that’s needed is a quick recharge during the lunch break and the vehicles are ready to go for several more hours.

- Cn be recharged even during short breaks

- Costly and time-consuming battery changes are no longer necessary

- High degree of system efficiency

- Combination of Linde Li-ION battery and Linde charger increases the energy yield by 30% compared to lead-acid batteries. This leads to lower energy costs.

Learn More: Explore the Power of Lithium Ion Batteries and Chargers

Economic Sustainability

- With the world’s population increasing and environmental problems from energy use and industry becoming more severe, it’s crucial to stop further harm.

- Our responsibility is to safeguard a healthy planet for our future and reduce harm to nature’s diverse ecosystems.

- For businesses, sustainability means operating in ways that don’t harm the environment and ensuring future growth without causing too much damage.

Learn More: Green Warehouse

Zero Emission Forklift Mandate

With the Zero Emission Forklifts Regulation, CARB plans to ban sales of all new forklifts that are not zero-emission by 2026 to improve air quality and reduce pollution.

- Starting in 2026, businesses cannot purchase or lease new internal combustion (IC) engine forklifts

- Mandates the replacement of propane forklifts with zero-emission engines such as electric

Learn More: Zero-Emission Forklift Regulation – Fleet Impact?

How Can Total Warehouse Help?

Expert Consultation: We provide the right electric forklifts and ensure compliance with CARB regulations.

Zero-Emission Options: Our electric forklifts meet zero-emission standards and fit your fleet needs.

Incentives: We guide you through state incentives, tax credits, and rebates.

Transition Support: We support in phasing out old forklifts for electric models and upgrading infrastructure.

Learn More: Total Warehouse’s Electric Energy Solutions

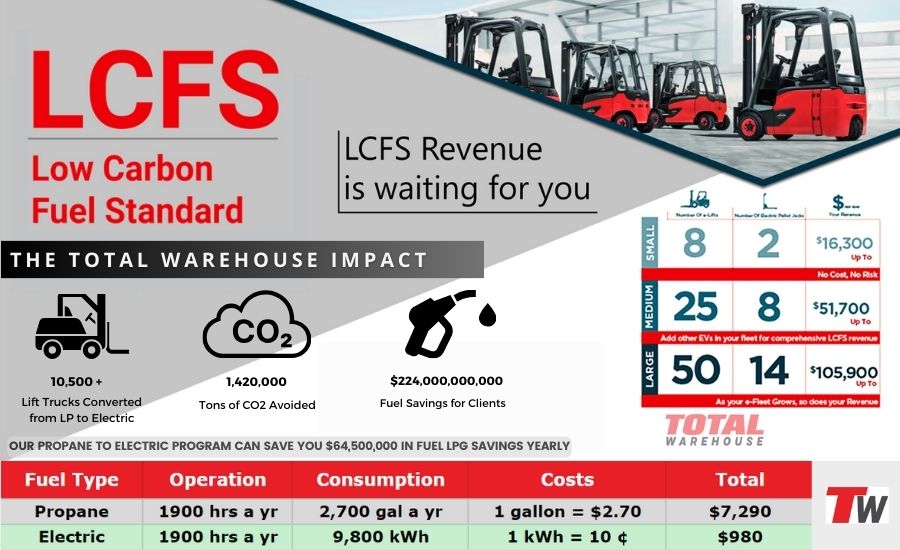

The Energy Costs Comparison Calculator

Estimate Your Savings by Transitioning from Propane to Electric Energy

Considering a shift to electric? Our Cost Savings Calculator offers a straightforward, data-informed comparison tailored to your fleet’s usage—giving you a clear view of the potential savings in fuel, maintenance, and overall operating costs.

LINDE Li-ION Chargers

Complete Energy Solution

Combine Linde Li-ION battery and Linde charger to increase energy yield by 30% compared to lead-acid batteries, increase vehicle availability and make operations more economical, efficient, safe, and sustainable.

- Reduce Fuel Costs by Up To 75%

- Perform Maintenance With 60% Fewer Parts

- Typical ROI Is Less Than 2 Years

- Vehicle control and battery management are perfectly aligned – using CAN bus interface.

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.