Key Features

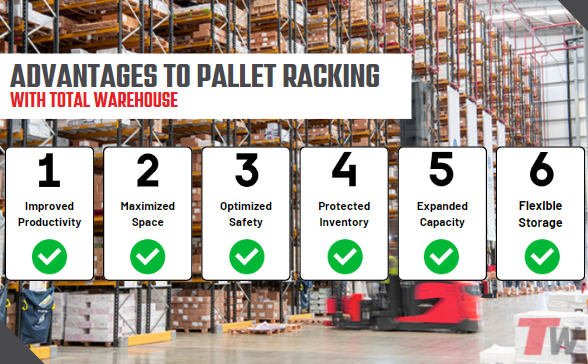

Advantages to Pallet Racking Systems

Identifying the right pallet racking system optimizes loading, unloading, and overall warehouse efficiency, but can be a challenging decision.

With our expert guidance, we offer personalized and customized systems for your needs. We design, integrate, and implement top-tier material handling solutions with the latest engineering and technology.

Industrial Pallet Racks in Warehouses

Pallet storage racks are one of the most popular types of warehouse storage systems used today. Because of the wide variety of styles and sizes to choose from, it is commonly used by warehouses and distribution centers for industrial storage, as well as for simple home storage projects.

Total Warehouse carries a wide variety of new and used warehouse storage rack brands and styles to fit any space. We also carry a wide assortment of accessories to add on to or customize any currently installed warehouse rack systems.

Enhance Safety In Your Building

Pallet packing systems are a smart way to enhance safety in your building. By installing clear, properly-sized aisles and pallet shelves, you ensure forklifts can maneuver safely while storing products to code, reducing the risk of accidents. Additionally, these systems help maximize warehouse storage and minimize operational expenses, creating a more efficient and cost-effective operation!

View Our Catalog: Catalog Page

Selecting The Best Pallet Rack

Do you work in or run a warehouse operation? If so, your warehouse is probably full of pallet racks that store all of your precious products and goods. There are many different types of industrial pallet shelvings configurations that can be selected by end users depending on their storage needs.

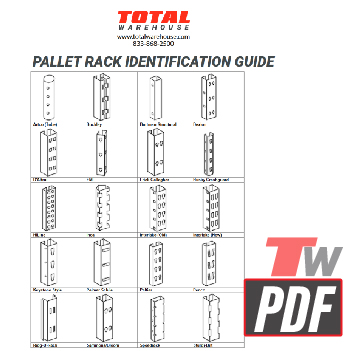

Examples Include: Interlake Old Style Tear Drop, Kingway Tear Drop, USP Tear Drop, Speed Rack Tear Drop, Mecalux Tear Drop, Lyon Metal Tear Drop, Interlake New Style Tear Drop, Space Rack Tear Drop, Bull Dog Tear Drop, Highline, Buckley, Unarco T-Bolt, Penco Slotted, Redi Rack, Frick Gallagher, Keystone, Palletier Old Style, Speed Rack, Husky Slotted, Buckley Master, Republic Keystone, Triple A, Cantennial, EMI Arrowstar, Amerilock, Prest Tear Drop, Palletier New Style, Sammons, EMI, Artco, Unarco 2, Ace Rack, Hiline, Prest Web Style, Strudi Built, Ridge U Rack, Burtman, Palmershile, Speed Rack, Structural Rack, Amerack and MI-Rack

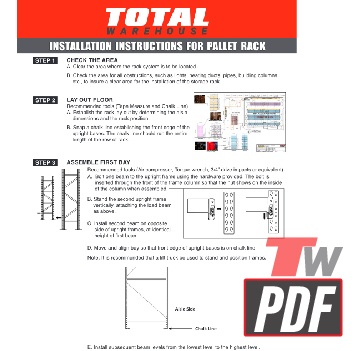

Installing and Dismantling Pallet Rack

Installing or dismantling pallet racks is not a DIY task. With numerous factors to consider, it’s crucial to prioritize safety—for your employees, products, building, and equipment. Avoid risks and hazards by entrusting this project to an experienced crew. Hiring professionals ensures the job is done efficiently and safely.

View Our Engineering Solutions

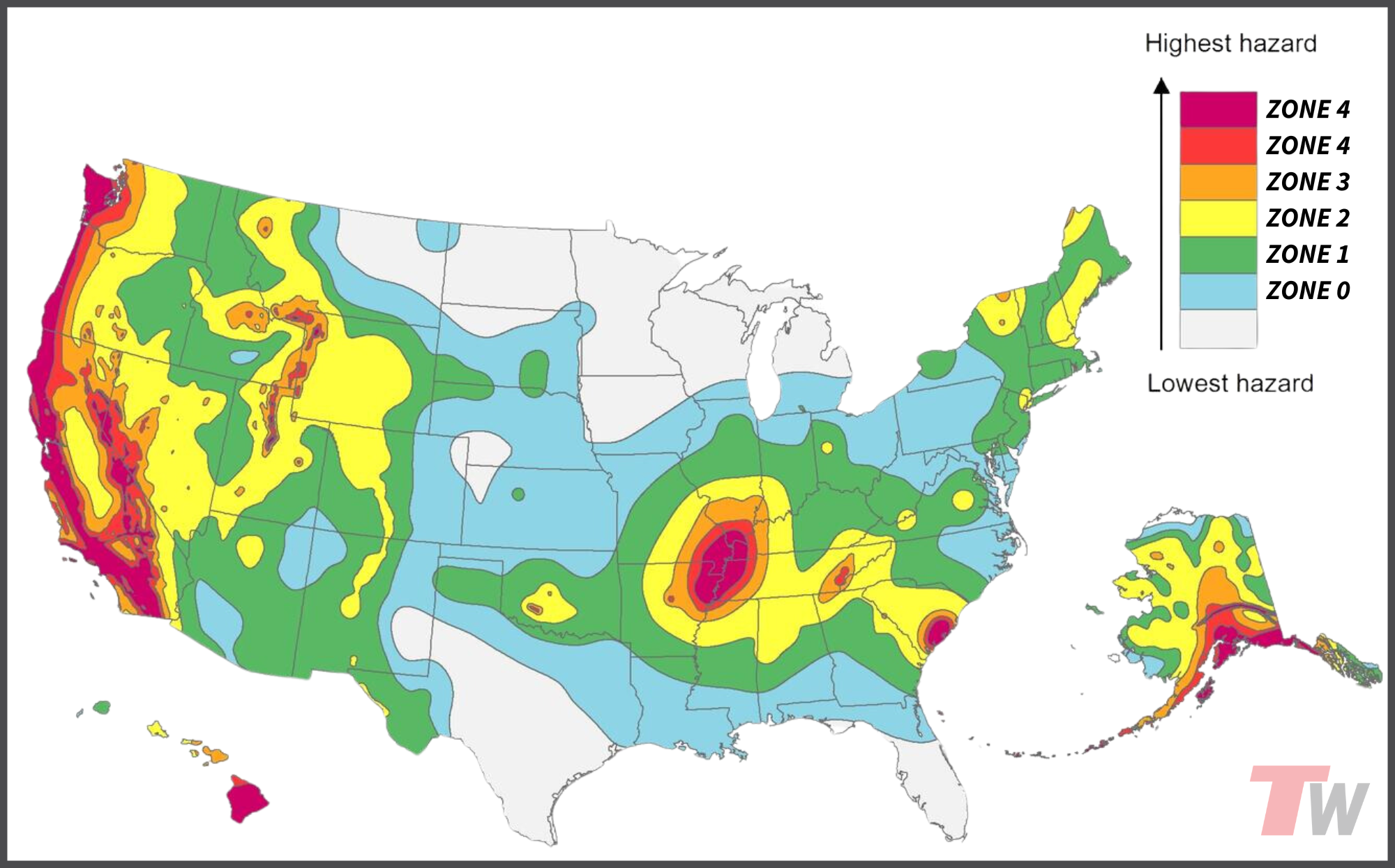

Why Seismic Zones Matters in Warehouse Rack

Seismic zones are crucial for warehouse racking as they determine the level of earthquake resistance required to ensure safety and compliance. Properly designed racking systems in high-risk seismic areas prevent collapses, protecting inventory, employees, and operations. Adhering to seismic standards reduces damage, minimizes downtime, and enhances overall warehouse stability.

Partner with Total Warehouse Engineers for seismic-compliant racking.

Q: What is pallet racking? A: Pallet racking is a storage system designed to hold palletized goods in a warehouse, optimizing vertical space and maximizing storage density.

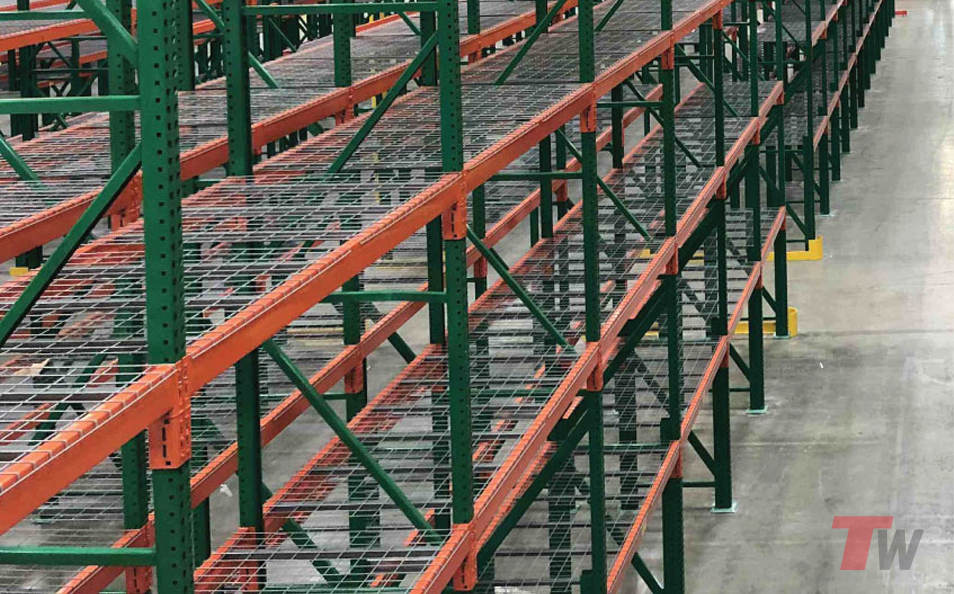

Q: What are the main components of a pallet racking system? A: The key components of pallet racking include: Upright frames are the vertical supports that provide the backbone of the structure. Beams are the horizontal members that connect to the uprights to create load-bearing levels. Safety accessories such as wire decking, backstops, and post protectors increase safety and prevent damage.

Q: What are the benefits of using pallet racking? A: Pallet racking offers several advantages: It increases storage space by maximizing vertical space, allowing you to store more within your existing footprint. It improves organization by creating designated storage areas for different products, promoting efficiency. It enhances accessibility by facilitating easy loading and unloading of pallets using forklifts. It increases safety by reducing the risk of product damage and accidents compared to floor stacking.

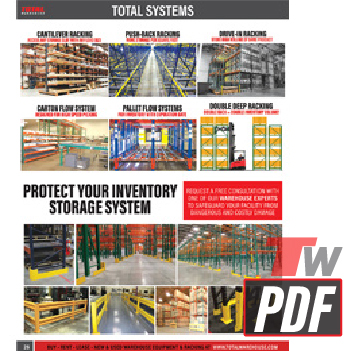

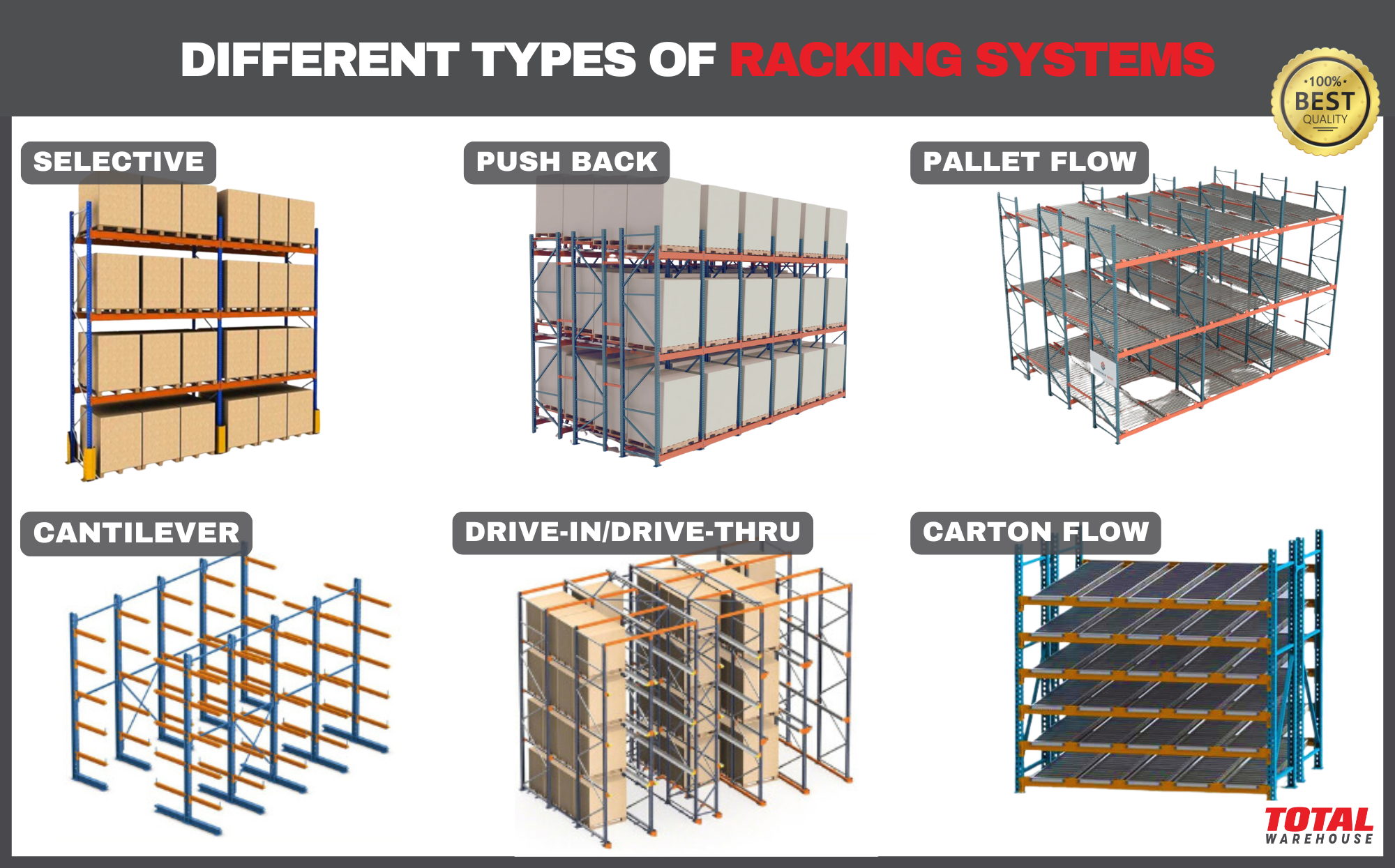

Q: What is selective pallet racking? A: Selective pallet racking is the most common type, providing direct access to every pallet, making it ideal for diverse inventory with frequent picking.

Q: What is drive-in/drive-thru racking? A: Drive-in racking allows forklifts to enter the rack system for high-density storage, but limits access (Last-In, First-Out). Drive-thru allows entry and exit from both sides.

Q: What is push-back racking? A: Push-back racking uses a system of inclined rails and carts for medium-density storage and Last-In-First-Out (LIFO) retrieval.

Q: What is pallet flow racking? A: Pallet flow racking has gravity-fed rollers or rails, creating First-In, First-Out (FIFO) retrieval. It is ideal for time-sensitive inventory.

Q: What is double deep pallet racking? A: Double deep pallet racking is a storage system where pallets are stored two rows deep, back-to-back, increasing storage density. This setup requires specialized forklifts to access the back row, making it more space-efficient than single-deep racking. It usually operates on a Last In, First Out (LIFO) basis, though First In, First Out (FIFO) is possible with careful management. It’s a cost-effective solution for warehouses that prioritize storage capacity over immediate pallet selectivity.

Q: What other types of specialty pallet racking systems are available? A: There are many other specialized pallet racking systems, including cantilever racking for long, bulky loads, mobile pallet racking for maximizing space in areas with limited floor space, and carton flow racking for high-volume order picking of smaller items.

Q: How do I determine the right pallet racking size for my warehouse? A: To determine the right pallet racking size, consider the ceiling height and clear height under obstructions, pallet dimensions, forklift specifications, floor loading capacity, and inventory volume and throughput.

Q: What is the difference between teardrop pallet racking and structural pallet racking? A: Teardrop racking is the most versatile, offering easy beam adjustment using a teardrop-shaped hole design. Structural racking uses bolted connections, often for heavier loads or seismic areas.

Q: What materials are pallet racking systems made from? A: Pallet racking systems are primarily made from high-strength steel. Coatings like powder coating or galvanization offer additional durability.

Q: Are there any safety regulations for pallet racking? A: Yes, both OSHA and industry-specific standards like RMI (Rack Manufacturers Institute) provide guidelines for safe pallet rack design, installation, and use.

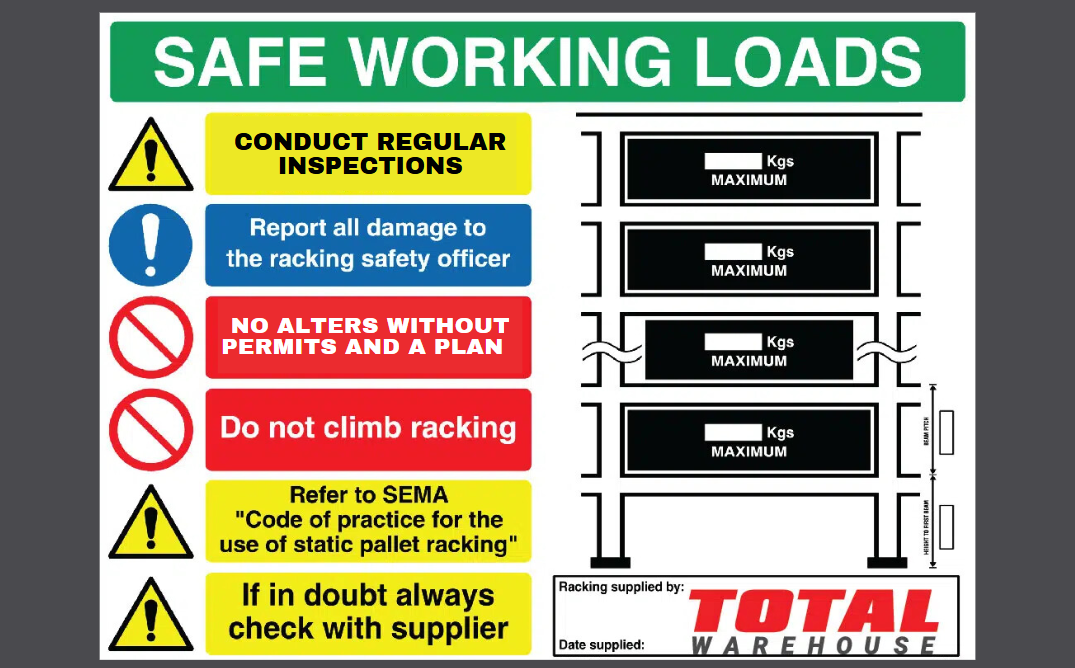

Q: How can I prevent pallet racking damage? A: To prevent pallet racking damage, regularly inspect the system by qualified personnel, use appropriate safety accessories, ensure proper forklift operator training, and do not overload racks beyond their weight capacity.

Q: What are some common signs of pallet rack damage? A: Common signs of pallet rack damage include bent or deformed uprights or beams, damaged connections or bracing, loose or missing safety components, and leaning or instability in the rack structure.

Q: What’s the difference between pallet racking and shelving? A: Pallet racking is designed for storing full pallets, typically accessed with forklifts. Shelving is for smaller items or cases and is often hand-loaded.

Q: What types of industrial storage racks are available? A: Common industrial storage racks include wire shelving, rivet shelving, and bulk storage racks.

Q: What factors should I consider when choosing shelving for my warehouse? A: When choosing shelving, consider the item size and weight, space constraints, adjustability, and accessibility.

Q: Can I use pallet racking for hand-picking? A: Yes, you can use pallet racking for hand-picking with the addition of accessories like wire decking for safe walking surfaces and dividers to organize items on the lower levels.

Q: Do I need a permit to install pallet racking? A: Permit requirements vary by location, so check with your local building department for specific regulations in your area.

Q: Can I install pallet racking myself? A: While basic assembly is possible, it’s generally recommended to have professional installation for large-scale racking systems to ensure safety and structural integrity.

Q: How much does pallet racking cost? A: The cost of pallet racking depends on factors such as the type of racking system, size and capacity requirements, and whether you’re purchasing new or used equipment, as well as installation costs.

Q: Where can I buy pallet racking? A: You can buy pallet racking from specialized material handling equipment suppliers, used equipment dealers, and online marketplaces, though you should verify the condition and specifications carefully when purchasing used equipment.

Q: Can I buy used pallet racking? A: Yes, buying used pallet racking can be a cost-effective option, but you should ensure it has been inspected by a qualified professional and that it meets your specifications.

Q: Should I rent or buy pallet racking? A: When deciding to rent or buy pallet racking, consider factors such as the duration of need, your budget, the flexibility to change your setup, and whether you want long-term ownership of the equipment.

Q: Can pallet racking be customized? A: Yes, many pallet racking systems can be customized with different sizes and configurations, safety accessories, and colors and finishes to match your branding or warehouse environment.

Q: What is the lifespan of a pallet racking system? A: A well-maintained pallet racking system can last for many years, as long as regular inspections and proper usage are maintained.

Q: How do I clean and maintain my pallet racking system? A: General maintenance includes regularly cleaning to remove dust and debris, periodically tightening bolts and connectors, and replacing damaged components promptly.

Q: Where can I find more information about pallet racking, industrial storage racks, and warehouse shelving? A: Helpful resources include the Total Warehouse website, material handling industry publications and blogs, and manufacturers’ websites and product literature.

Q: Can I relocate my pallet racking system? A: Yes, most pallet racking systems can be disassembled and relocated, though it’s recommended to seek assistance from a professional installer for a safe process, particularly for complex or large systems.

Q: Do pallet racks need to be anchored? A: Yes, anchoring pallet racks to the floor is essential for stability and preventing tipping hazards, especially in seismic zones or with heavy loads.

Q: How often should I inspect my pallet racking? A: Regular inspections are crucial for maintaining pallet rack safety. This includes daily informal visual checks by forklift operators, weekly or monthly formal checks by a designated safety person, and comprehensive yearly inspections by a qualified rack inspector.

Q: What should I look for during a pallet rack inspection? A: A thorough pallet rack inspection should focus on identifying damaged or deformed components, missing or loose safety components, signs of overloading or improper loading practices, and the overall stability of the rack structure.

Q: Can I repair damaged pallet racking? A: Minor damage may be repairable with approved replacement parts and procedures, but major damage or compromises to the structural integrity often require full component replacement.

Q: What are some environmental factors to consider with pallet racking? A: Environmental factors to consider include temperature fluctuations, moisture and humidity, and exposure to chemicals, all of which can affect the materials and performance of the pallet racking system.

Q: Can I use pallet racking outdoors? A: Yes, some outdoor-rated pallet racking systems are designed for outdoor use, typically with galvanized or other weather-resistant coatings.

Q: What is wire decking and what are its benefits? A: Wire decking is a mesh-like surface that fits onto pallet rack beams. Its benefits include improved safety by preventing pallets or items from falling through, enhanced airflow, and better visibility for inventory and safety checks.

Q: Are there different types of wire decking? A: Yes, wire decking comes in various styles, including flush decking, waterfall decking, and channel style decking, each with different features and compatibility with specific beam types.

Q: How do I choose the right wire decking for my pallet racking? A: When choosing wire decking, consider the weight capacity, beam type compatibility, and any fire safety requirements, such as sprinkler clearance.

Q: Can I use pallet racking in a cold storage warehouse? A: Yes, specialized pallet racking designed for cold storage environments may be necessary, often with coatings to resist condensation and potential rust.

Q: What is the difference between roll-formed and structural pallet racking? A: Roll-formed pallet racking is made from thinner steel that’s shaped into uprights and beams, making it generally lighter and less expensive. Structural pallet racking uses heavier gauge steel and bolted construction, offering higher load capacities.

Q: Are there any tax advantages to buying pallet racking? A: Yes, pallet racking may qualify for tax deductions or accelerated depreciation as business equipment, so consult with a tax advisor for specific information.

Q: How can I calculate how much storage capacity my pallet racking system will provide? A: To estimate storage capacity, consider the number of available pallet positions, the usable depth of storage per beam level, and the number of levels within the height restrictions of your warehouse.

Q: Is there a weight limit for pallets stored on pallet racking? A: Yes, each beam level has a specific weight capacity, and it’s crucial to adhere to these limits to prevent overloading and potential collapses.

Q: What is a pallet support bar and when do I need one? A: Pallet support bars are placed between beams to provide additional support for pallets, particularly those with open bottoms or uneven weight distribution.

Q: How much space should I leave between pallet loads? A: Maintaining a small gap, generally a few inches, between pallets improves airflow, reduces the risk of damage, and can help with fire safety.

Q: Do different forklifts have different pallet racking requirements? A: Yes, the type of forklift influences the necessary aisle widths between racking, as specifications like turn radius and reach height should be considered.

Q: Can I mix and match different brands of pallet racking? A: Mixing brands is sometimes possible, but compatibility can be a challenge, so it’s recommended to seek professional advice to ensure components align correctly and that load capacities are not compromised.

Q: What are some accessories that can be added to pallet racking? A: Common pallet racking accessories include row spacers, backstops/beam guards, column/post protectors, and wire dividers.

Q: How do I ensure my warehouse complies with pallet racking safety regulations? A: To improve compliance, use racking from reputable manufacturers, have professional installation, train employees on safe loading and operation, and conduct regular inspections and maintenance.

Q: Can I integrate pallet racking with conveyors? A: Yes, pallet racking can often be integrated with conveyor systems for automated loading or unloading, streamlining the flow of goods in your warehouse.

Q: What types of flooring are best for use with pallet racking? A: Concrete floors are ideal for their durability and ability to support the weight of loaded pallet racks, as long as the floor is level and free of major cracks or damage.

Q: How much aisle space do I need for my pallet racking? A: The required aisle space depends on factors such as the type of forklift, pallet size, racking configuration, and workflow, with wider aisles often better for frequent picking.

Q: Can I change the configuration of my pallet racking after it’s installed? A: Many pallet racking systems, particularly those with teardrop connections, are designed for adjustability, allowing you to modify beam heights or add accessories as your needs change.

Q: What should I consider when designing a pallet racking layout? A: When designing a pallet racking layout, you should aim to maximize storage density within your space constraints, optimize traffic flow for efficiency and safety, match storage type to your inventory needs, and accommodate forklift requirements.

Q: Is there software that can help me design a pallet racking layout? A: Yes, specialized warehouse design software often offers modules for pallet rack layout planning, helping you visualize different configurations and optimize your space.

Q: Can I use pallet racking to help with inventory management? A: Yes, pallet racking can support inventory management strategies by assigning specific locations, implementing FIFO or LIFO systems, and using barcoding or labeling for easier tracking.

Q: What are some common mistakes to avoid with pallet racking? A: Common mistakes to avoid include overloading, improper loading, forklift damage, and neglecting regular maintenance and inspections.

Q: How can I improve the efficiency of my pallet racking operations? A: To improve efficiency, optimize the layout for your product mix and turnover, implement a warehouse management system, use appropriate safety accessories to reduce damage and delays, and train employees on proper pallet handling and safety procedures.

Q: Can I use pallet racking in a seismic zone? A: Yes, but seismic-rated pallet racking, specifically engineered and braced to withstand seismic forces, is crucial in earthquake-prone areas.

Q: Are there energy-efficient options for pallet racking? A: While the racking itself might not directly consume energy, your choice of racking can impact warehouse energy efficiency by maximizing density to reduce space that needs to be heated or cooled, integrating lighting for safe picking, and enabling automation for potential energy savings.

Q: How does pallet racking affect my warehouse lighting? A: Pallet racking layout can significantly impact lighting, as tall racks and narrow aisles may create shadows, requiring consideration of aisle lighting and the use of wire decking, which allows more light to pass through than solid shelving.

Q: Does pallet racking require fire sprinklers? A: In many cases, yes. Fire codes often mandate sprinklers in warehouses with pallet racking, especially for storing combustible materials.

Q: How do I incorporate fire safety into my pallet racking design? A: When incorporating fire safety, consult fire codes, choose between in-rack sprinklers or standard ceiling systems, consider flue spaces within the racking for sprinkler access, and ensure forklifts and aisles don’t obstruct sprinkler coverage.

Q: What is the environmental impact of pallet racking? A: Pallet racking can have both positive and negative environmental impacts, with the positives including improved space usage that can reduce the overall facility footprint, and the negatives including the impact of manufacturing, though steel is highly recyclable, making used racking an eco-friendly option.

Q: What is the future of pallet racking? A: Key trends in pallet racking development include increased automation, a focus on adaptability and reconfigurability, and the incorporation of smart sensors and technology for load monitoring and safety.

Q: I’m a small business owner with limited storage space. Is pallet racking right for me? A: For smaller operations, pallet racking might not be the most suitable option, as smaller quantities may not fully utilize high-density pallet racking. Lighter-duty or used racking might be more cost-effective, or you could explore alternatives like high-density shelving if pallet handling isn’t essential.

- Learn about the different types of pallet racking systems including drive-in, selective, etc

- Learn about the different pallet racking styles including teardrop, structural, etc

Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

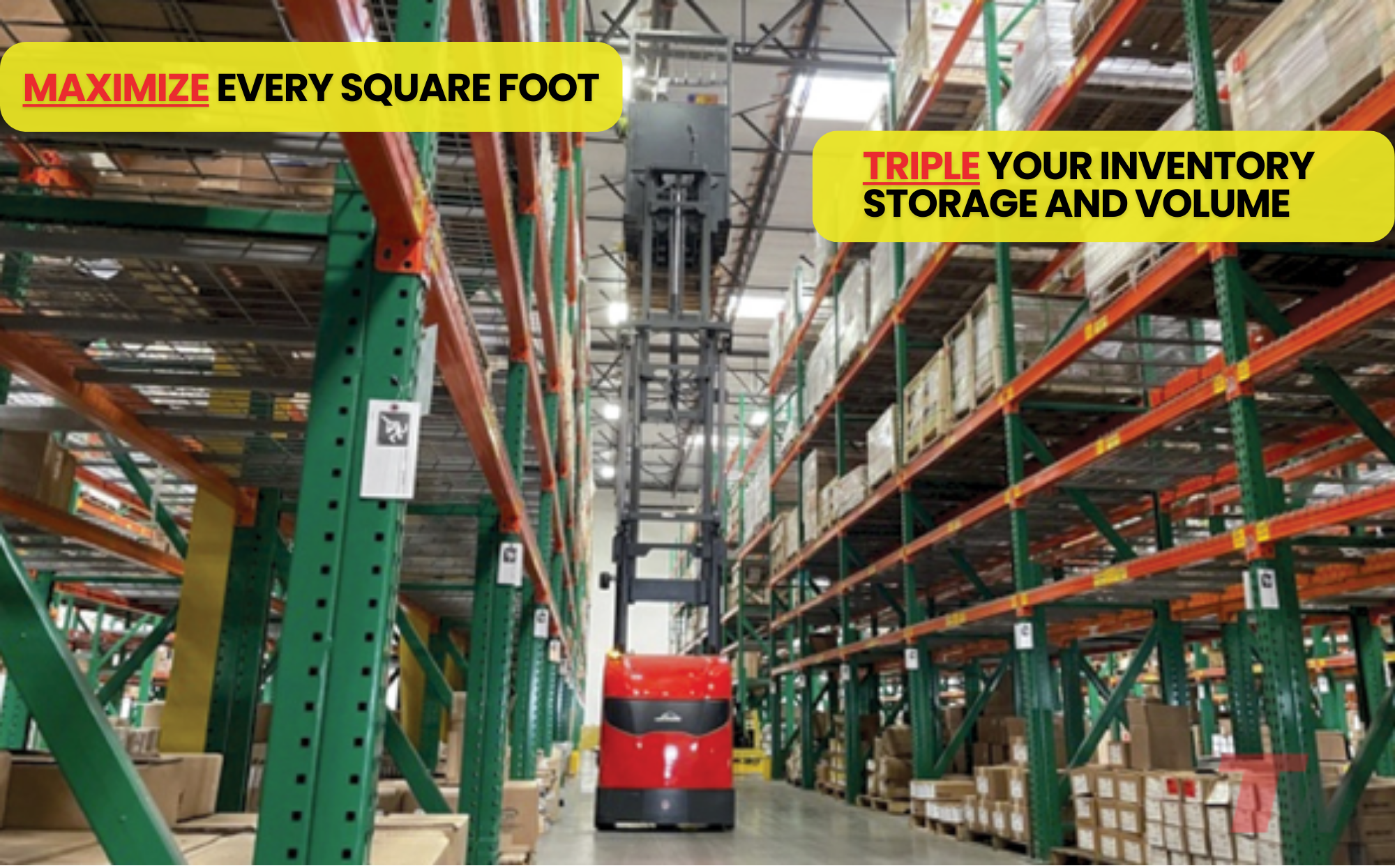

Space Saving

Are You Maximizing Your Sq Ft?

A key advantage to using a pallet racking system is their space-saving design, optimizing vertical storage in warehouses. This efficiency boosts profits by expanding storage capacity, enhancing ease of pallet maneuvering, and ensuring safety, especially for heavy stock.

- Enables easy access to highest number of SKU’s

- Efficient maneuvering of forklift trucks in wide aisles

- Use vertical space effectively with a simple component profile.

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.