Key Features

Why Proper Racking Installation Matters

1. Safety First: Proper pallet racking installation protects workers by reducing the risk of collapses and accidents, creating a secure warehouse environment.

2. Structural Integrity: Well-installed racking ensures durability and stability, preventing costly damage to inventory and equipment.

3. Maximized Space Efficiency: Optimized racking layouts improve organization, increase storage capacity, and enhance workflow efficiency.

4. Regulatory Compliance: Meeting industry safety standards helps pass inspections, avoid fines, and maintain operational legality.

5. Long-Term Cost Savings: Investing in professional racking installation reduces maintenance costs, minimizes downtime, and enhances overall warehouse profitability.

Our Plan for Pallet Rack Installation

Space Assessment:

Measure floor area, ceiling height, and identify obstacles like pillars or beams. Ensure the racking system fits your layout, meets seismic requirements, and can be securely anchored to a stable floor.

Storage Needs:

Evaluate the type, size, and weight of items you’ll store. Choose a racking system that meets your capacity, accessibility, and inventory rotation needs (FIFO/LIFO).

Rack Selection:

Based on space and storage needs, select racks that accommodate your operation’s requirements, including floor capacity, ceiling height, and forklift access. Consider future growth.

Safety Compliance:

Adhere to OSHA and local safety regulations. Train personnel, use PPE, and secure necessary permits with engineer approval before installation.

OSHA requirements for Warehouse Racking

OSHA mandates that warehouse racking systems meet safety standards, including load ratings, stability, and collapse prevention. Regular inspections, maintenance, and adherence to load limits are required. Racking must also avoid obstructing fire safety equipment or exits and must be properly anchored and aligned.

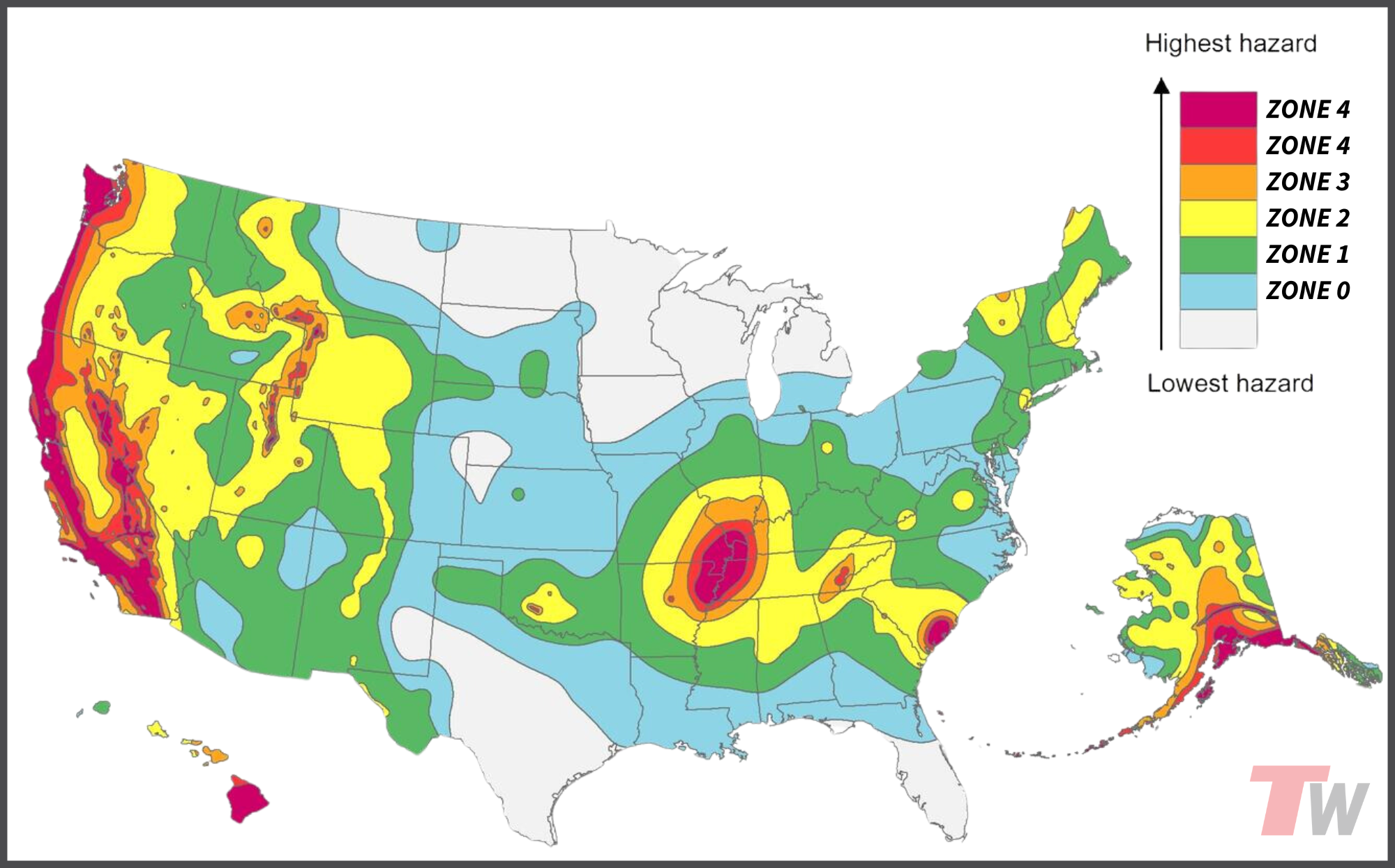

Why Seismic Zones Matters in Warehouse Rack

Seismic zones are crucial for warehouse racking as they determine the level of earthquake resistance required to ensure safety and compliance. Properly designed racking systems in high-risk seismic areas prevent collapses, protecting inventory, employees, and operations. Adhering to seismic standards reduces damage, minimizes downtime, and enhances overall warehouse stability.

Partner with Total Warehouse Engineers for seismic-compliant racking.

Rack Project Process

4 Easy Steps

1. YOU CALL. The first step in the journey towards your incredible new warehouse storage system starts by contacting Total Warehouse.

2. WE ENGINEER. No engineering project is too big or small for Total Warehouse.

3. WE DELIVER. We have a massive stock of all uprights, beams, and decking. Your project will never be stalled by waiting on shipments.

4. WE INSTALL. Our installation teams are professional, punctual, and well-equipped to handle any potential obstacles that may arise during your project.

50 Years Dependability

Transforming Businesses Since 1972

Our experts have years of pallet racking installation experience, including repairing, removing, and fixing pallet rack systems. We can install all types of pallet racking, shelving, conveyors, and other storage equipment.

- Certified and Licensed Professionals

- Project Management Services for All Installations

- Permit Submittal & Acquisition

- Ensure Adherence to OSHA Guidelines

Still not convinced?

Let us help you decide.

The warehouse experts at TOTAL WAREHOUSE have decades of experience with every type of industry and operation. We know the exact equipment and storage system combination needed to increase your output. Give us a call and let's grow your business together.